Custom Parts. Precision Delivered.

From prototyping to full-scale production, LS Manufacturing delivers high-quality custom parts with preci-sion. We offer CNC machining, sheet metal fabrication, 3D printing, and more. Instant quoting, fast turnaround, global delivery.

- 80+ materials, 40+ surface finishes

- 25% more affordable | No MOQ required

- Delivery in as fast as 1 day

- ISO 9001:2015, ISO 13485, ISO 14001, and IATF 16949 certified

Start Prototyping Today!

Upload your design files for instant pricing and free DFM analysis.

Get instant pricing, project lead times, and DFM feedback.

STEP | STP | SLDPRT | STL | DXF | IPT | X_T | X_B | 3DXML | CATPART | PRT | SAT | 3MF | JT files

File size: ≤15MB

If file>15MB plese send to info@longshengmfg.com All uploads are secure and confidential.

All uploads are secure and confidential.

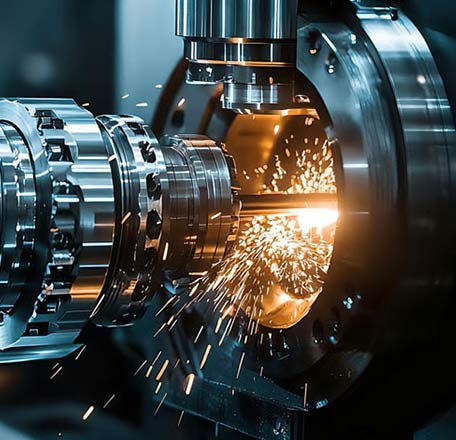

Our Manufacturing Capabilities

With over 15 years of manufacturing experience, we handle cnc parts with tolerance of up to 0.005mm, same day quotation, and 72 hours delivery. We have produced over 80,000 different parts of different quantity. Our aim is to provide top quality and high efficiency metal parts machining services for prototyping as well as mass production customers.

How To Order Parts

Your time is precious, and we are well aware that you want efficient delivery. We streamline the innovation cycle into four simple but effective steps. In just 3 days, you can have flawless parts! Start your machining project now!

Upload CAD File

Upload designs for one or multiple parts.

Free Quote & DFM Analysis

Receive quote and Design for Manufacturing feedback.

Order Confirmation & Start Production

Confirm order details. Manufacturing starts immediately with sorting options available.

Quality Inspection & Report

Rigorous quality checks performed. Detailed inspection report provided.

Fast Shipping

Your parts delivered to your address within days.

From Rapid Prototyping To Production

LS Manufacturing supports your complete product lifecycle with flexible manufacturing solutions for every scale.

Rapid Prototyping

Transform design concepts into physical samples in days. Verify your design quickly before committing to full production.

- Instant quotes

- Fast DFM feedback

- High-quality samples

- Quick design validation

Low-Volume Manufacturing

Cost-effective soft tooling bridges the gap between prototyping and final production. Launch products faster with minimal upfront investment.

- Lower tooling costs

- Fast DFM feedback

- Fast turnaround

- Market validation before scaling

On-Demand Production

Scalable manufacturing for production runs. Our engineering team optimizes quality and cost for your specific requirements.

- DFM optimization support

- Dedicated project management

- Quality inspection & reports

- Consistent batch quality

Why you can trust LS Manufacturing ?

We strictly implement ISO quality standards and maintain ISO 9001:2015 certification. Our advanced production capabilities feature precision tooling, in-house measurement and testing equipment, and rigorous quality control to ensure every part meets your exact specifications.

Instant Quoting

Upload CAD files for quote within hours. Transparent pricing with detailed cost breakdown.

15+ Years Industry Experience

Expert engineers with comprehensive manufacturing expertise. From concept to production, we deliver solutions across multiple processes for prototypes and mass production.

80,000+ Projects Delivered

Proven track record with global customers. ±0.005mm″ tolerance capability. Fast turnaround, reliable delivery.

Dedicated Support

24/7 engineering support. Professional DFM feedback. Customized solutions for your specific needs.

Rigorous Quality Control for Precision Parts

LS Manufacturing’s experienced quality control team utilizes advanced equipment including CMMs and other precision inspection tools. We perform comprehensive First Article Inspection (FAI) to verify every batch meets design specifications.

- Our thorough inspection services cover the entire manufacturing process to ensure every part delivered is consistent and reliable.Skilled QC team overseeing production.

- High-precision CMM inspection

- Strict First Article Inspection (FAI) process

- Comprehensive inspection services

- ISO 9001:2015, ISO 13485, ISO 14001, and IATF 16949

Choose LS Manufacturing for your CNC machining needs and experience our commitment to quality through our rigorous quality control processes. Contact us today to discuss your project and see how we can help you achieve your goals.

High Quality On Time Delivery

Experience our commitment to unparalleled precision and superior quality control. We utilize cutting-edge inspection equipment in our CNC machining process to ensure every part meets rigorous industry standards and exceeds customer expectations. Take a closer look at our leading-edge inspection tools that make our precise, reliable, and efficient manufacturing possible.

Quality Control And Testing

· Advanced facilities

· On-site quality engineers

· Inspection reports for every

Professional Engineering Team

· Customized solutions

· Professional support 24/7

Refund And Repair Policy

· Handle issues within 3 days

· Professional after-sales service team

After-Sales Service Guarantee

. Rapid issue resolution

. Professional support team

. Quality guarantee coverage

Client's Reviews

Listen to our customers’ voices! We have received praise and satisfactory evaluations from many customers.

Put Your parts Into production Today

All information and uploads are secure and confidential.

Industry Applications

LS Manufacturing serves diverse industries, including automotive, aerospace, medical devices, and consumer electronics.

Our advanced technology and expertise ensure high-quality, customized solutions for each sector's unique needs.

Automotive Industry

▲Project Background: Leading automaker required precision parts for a new electric vehicle platform.

Challenge: Components needed to meet stringent quality standards, compressed timelines, and cost optimization targets.

Solution: We delivered high-precision CNC machined parts utilizing advanced tooling and streamlined production workflows.

Results: Project completed ahead of schedule with all quality and performance metrics met, ensuring successful vehicle launch.

Medical Devices

▲Project Background: Medical device manufacturer needed precision components for an innovative surgical tool.

Challenge: Parts demanded superior precision, biocompatibility properties, and compliance with regulatory requirements.

Solution: We supplied precision CNC-turned components from medical-grade materials, meeting all biocompatibility and regulatory specifications.

Results: Surgical instruments successfully launched and performed reliably throughout clinical trials.

Consumer Electronics

▲Project Background: Consumer electronics leader needed complex parts for a next-generation smartwatch device.

Challenge: Components required extreme precision combined with premium surface finishes for compact, design-forward applications.

Solution: Advanced micro-machining techniques delivered intricate components with flawless finishes meeting all design and functional requirements.

Results: Smartwatch parts shipped on schedule, driving successful product launch and strong market reception.

Aerospace

▲Project Background: Aerospace manufacturer needed high-strength, lightweight components for satellite applications.

Challenge: Parts required extreme durability and compliance with rigorous aerospace certification standards.

Solution: High-grade titanium components manufactured using advanced CNC techniques ensuring strength, reliability, and precision.

Results: Satellite components achieved all performance standards and demonstrated exceptional reliability in orbital operation.

Industrial Equipment

▲Project Background: Industrial machinery manufacturer required precision components for advanced production systems.

Challenge: Parts needed superior durability to withstand intensive operational demands and ensure continuous machinery performance.

Solution: High-strength steel precision components manufactured to meet demanding industrial application requirements.

Results: Production system components improved machinery efficiency and extended service life, boosting overall productivity.

Precision Manufacturing Capabilities

Download Our Brochure to Get a Full

Overview of Our Manufacturing Capabilities

Access our technical documentation, covering all core processes, tolerance standards, material options, and industry case studies, to help you quickly evaluate project feasibility.

What's in the manual?

·High-definition product images and 3D cross-sections.

·Detailed process capabilities and tolerance standards, e.g., 5-axis CNC accuracy, injection mold lifespan.

·Comprehensive material options and surface finishes, e.g., titanium, PEEK, anodizing, sandblasting.

·Quality system certifications (ISO 9001) and industry case studies.

·A complete guide to our process from rapid prototyping to mass production.

Lead Capture Form

Simply enter your email to get the download link instantly

FAQ

1. What services does LS Manufacturing offer?

LS Manufacturing provides CNC machining, plastic injection molding, metal stamping, sheet metal fabrication, and various surface finishing solutions.

2. Can you manufacture custom parts based on my design?

3. Which industries do you serve?

4. How can I request a quote?

5. What is your typical lead time?

6. Do you offer prototyping services?

7. Can you handle low-volume production?

8. What surface finishes do you provide?

9. How do you ensure product quality?

10. Do you ship internationally?

News & Blog

The Ultimate Guide to Custom Gears: Optimize Design, Performance & Cost

CNC Turning Services in Georgia: Rapid Delivery and Local Support

From Design to Production — Fast, Reliable, Confidential.

- All information and uploads are secure and confidential.