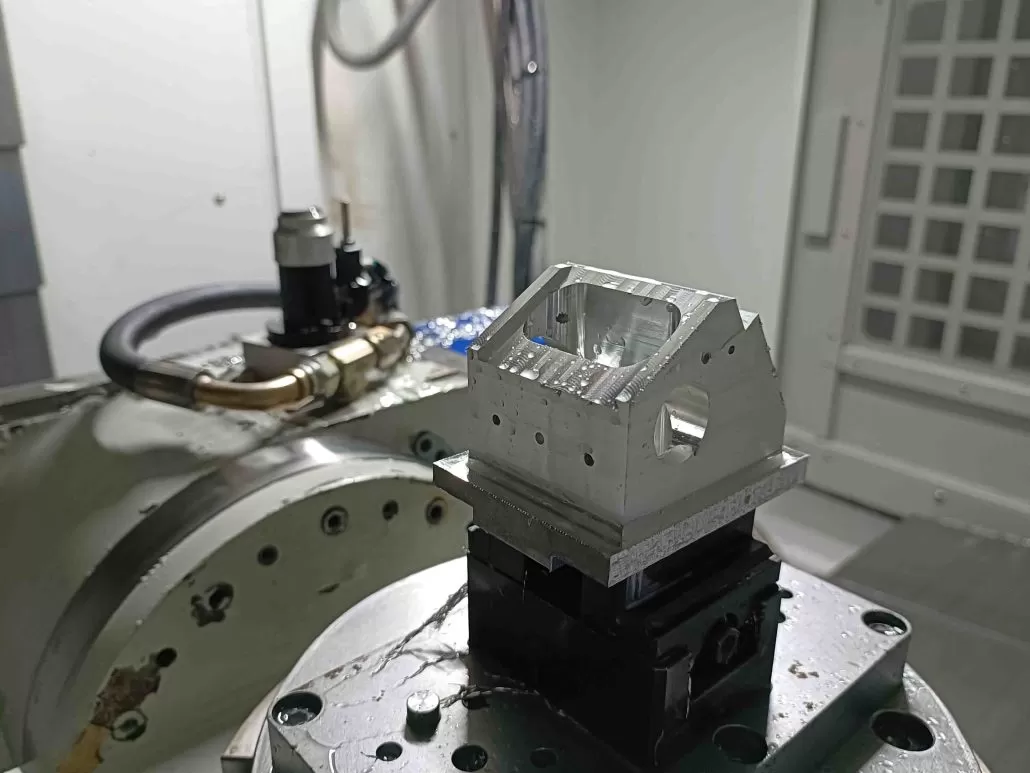

CNC machining refers to the use of computer numerical control (CNC) machines to manufacture parts and components for various industries. These machines use pre-programmed software to control the movement of cutting tools and other machine components, resulting in highly precise and accurate parts.

CNC machining is an essential part of modern manufacturing processes as it allows for the production of complex parts with high accuracy and repeatability. The use of CNC machines has revolutionized the manufacturing industry by increasing productivity, reducing waste, and improving overall quality.

what is CNC machining

CNC (Computer Numerical Control) Machining is a manufacturing process that uses computer software to control the movement of machines and tools to create custom parts and components. CNC machines are programmed to perform precise cuts and movements to produce parts with high accuracy and repeatability. This technology is commonly used in the aerospace, automotive, and medical industries to create complex parts that would be difficult or impossible to make by hand. CNC machines can work with a variety of materials, including metals, plastics, and wood.

10 CNC machining experience summary

To become a competent CNC machinist, one needs a combination of technical knowledge and practical skills. In this section, we will take a closer look at ten key experiences related to CNC machining that are necessary for success in this field.

1. Understanding of CNC programming languages such as G-code and M-code.

CNC machines operate using a set of commands that are inputted via a programming language. G-code and M-code are two of the most commonly used programming languages in CNC machining. A good CNC machinist should have a deep understanding of these programming languages to be able to produce accurate and precise parts.

2. Proficiency in operating CNC machines, including lathes, mills, and routers.

Operating a CNC machine requires a high level of skill and precision. A good CNC machinist should be proficient in operating various types of CNC machines such as lathes, mills, and routers. They should also be able to set up and configure these machines to produce parts accurately.

3. Ability to read technical drawings and blueprints.

A CNC machinist should be able to read and interpret technical drawings and blueprints accurately. This skill is essential for understanding the specifications of the part that needs to be produced and for creating a program that will result in the desired outcome.

4. Knowledge of cutting tools and their applications.

CNC machines use cutting tools to shape and form the raw material into the desired shape. A good CNC machinist should have a deep understanding of the different types of cutting tools and their applications. This knowledge is essential for choosing the right tool for the job and ensuring that the part is produced accurately.

5. Familiarity with various types of materials, including metals, plastics, and composites.

CNC machining involves the production of parts using various types of materials such as metals, plastics, and composites. A good CNC machinist should have a deep understanding of the properties of these materials and how they behave during the machining process.

6. Understanding of machine calibration and maintenance procedures.

CNC machines require regular calibration and maintenance to ensure that they function correctly. A good CNC machinist should have a deep understanding of the calibration and maintenance procedures for the machines they operate.

7. Experience with quality control and inspection methods, including the use of measuring tools.

Quality control and inspection are essential parts of the CNC machining process. A good CNC machinist should have experience with quality control and inspection methods such as the use of measuring tools. This experience is essential for ensuring that the parts produced meet the required specifications.

8. Knowledge of CAD/CAM software and its integration with CNC machines.

CAD/CAM software is an essential tool for CNC machinists as it allows them to create the programs needed to produce the desired parts. A good CNC machinist should have a deep understanding of CAD/CAM software and its integration with CNC machines.

9. Ability to troubleshoot and diagnose machine malfunctions.

CNC machines can experience malfunctions that can affect the production process. A good CNC machinist should have the ability to troubleshoot and diagnose these malfunctions quickly and efficiently. This skill is essential for minimizing downtime and ensuring that the production process runs smoothly.

10. Strong communication and collaboration skills, as CNC machining often involves teamwork and coordination with other departments.

CNC machining is often a collaborative process that involves multiple departments within an organization. A good CNC machinist should have strong communication and collaboration skills to ensure that the production process runs smoothly and that everyone involved is on the same page.

Overall, CNC machining requires a combination of technical knowledge, practical skills, and attention to detail. With the right training and experience, CNC machinists can produce high-quality parts that meet the specifications of their clients and industries.