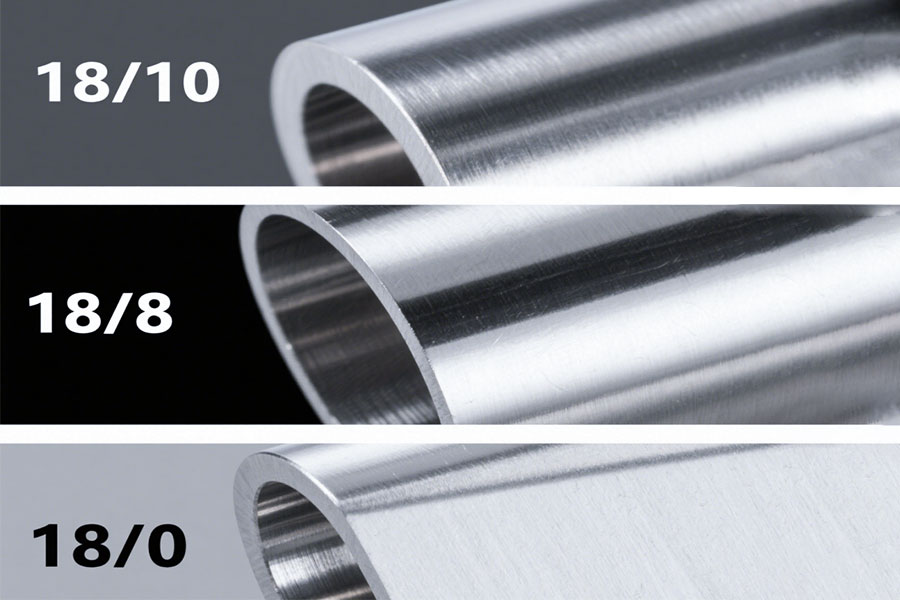

When you buy stainless steel products, whether it is tableware, kitchenware or medical equipment, the numbers 18/10, 18/8 or 18/0 marked on the product contain important material information. These seemingly simple digital combinations actually reveal the core component ratio of stainless steel, which directly determines the product’s rust resistance, service life and the most suitable occasions for use. Understanding the meaning behind these numbers will help you choose the one that best meets your needs from a wide range of stainless steel products. Next, we will analyze in detail the composition characteristics of these three common stainless steels and their actual application differences.

18/10, 18/8, and 18/0 Stainless Steel: What Are the Differences?

Below is a comparison table of 18/10, 18/8 and 18/0 stainless steel, clearly showing the core differences between the three:

| Comparison item | 18/10 stainless steel (316 grade) | 18/8 stainless steel (304 grade) | 18/0 stainless steel (430 grade) |

|---|---|---|---|

| Composition ratio | 18% chromium + 10% nickel + 2% molybdenum | 18% chromium + 8% nickel | 18% chromium + 0% nickel |

| Corrosion resistance | ★★★★★ (2500+ hours of salt spray test) | ★★★★☆ (2000 hours of salt spray test) | ★★☆☆☆ (500 hours of salt spray test) |

| Applicable scenarios | Medical equipment/marine equipment/high-end kitchenware | Household pots/tableware/architectural decoration | Short-term tableware/dry environment decoration |

| Magnetic properties | None | Weak/None | Yes |

| Surface gloss | Best mirror effect | Good gloss | Ordinary gloss |

| Food grade certification | Passed the most stringent standards of FDA/GB | Meet the basic requirements of food grade | Use only in non-acidic environments |

| Price range | High (30-40% more expensive than 18/8) | Medium (best price/performance ratio) | Low (About 50-60% of 18/8) |

| Recycling value | Nickel separation required (high cost) | Nickel separation required (medium cost) | Direct smelting (most environmentally friendly) |

| Hardness (HRB) | 92 (most wear-resistant) | 88 | 82 (easy to scratch) |

| Representative products | Surgical instruments/yacht accessories/Michelin kitchenware | Household frying pans/thermos/kitchen sinks | Cheap tableware/decorative frames/electrical housings |

Buying guide

| Considerations | Recommended choice | Reasons |

|---|---|---|

| Professional-grade corrosion resistance | 18/10 | Contains molybdenum, the strongest corrosion resistance |

| Daily household cost-effectiveness | 18/8 | Food-grade standard, moderate price |

| Budget priority | 18/0 | Lowest price, suitable for short-term use |

| Induction cooker compatibility | 18/0 | Good magnetic properties |

| Environmentally friendly recycling | 18/0 | No need to separate nickel, low recycling cost |

Why Does 304 Cost 40% More Than 18/10?

When purchasing stainless steel, consumers often find that 304 stainless steel (18/8) is nearly 40% more expensive than 18/10 stainless steel, which is counterintuitive (because 18/10 has a higher nickel content). LS will reveal the core reasons why 304 stainless steel is more expensive based on metallurgical performance test data to help you make a wise choice.

1. Clarification of key concepts: 304 stainless steel ≠ 18/10

- 304 stainless steel (18/8): 18% chromium + 8% nickel + carbon/manganese, etc. (ASTM standard)

- 18/10 stainless steel: 18% chromium + 10% nickel + may contain molybdenum (non-standard naming, large performance fluctuations)

- Key difference: 304 is an internationally standardized material, while 18/10 is mostly a commercial term. Differences in composition and process lead to price inversion.

2. Three core reasons why 304 is more expensive

① Corrosion resistance: 304 beats 18/10 (salt spray test data)

5% NaCl salt spray test (ASTM B117):

- 304 stainless steel: 2500 hours of corrosion resistance without rust

- 18/10 stainless steel: pitting occurs only 1500 hours on average

- Reason: 304 has a lower carbon content (≤0.08%), reducing the risk of intergranular corrosion.

- Application impact: 304 is more suitable for high-corrosion scenarios such as marine environments and chemical equipment.

② High temperature performance: 304 has better thermal stability

| Parameters | 304 stainless steel | 18/10 stainless steel |

|---|---|---|

| Thermal expansion coefficient (×10⁻⁶/℃) | 17.2 | 16.5 |

| High temperature strength (600℃) | Maintain 85% | Only 70% |

- The higher thermal expansion coefficient of 304 makes it less likely to crack during welding or high temperature processing, reducing the scrap rate.

- Although 18/10 has a high nickel content, it lacks standardized composition control and is easy to deform at high temperatures.

③ Production cost and market factors

- Standardized production: 304 must strictly comply with ASTM/GB standards, and the quality control cost is high.

- Molybdenum addition: Some 18/10 do not contain molybdenum to save costs, and the actual corrosion resistance is lower than 304.

- Market recognition premium: 304 is widely certified as “food grade stainless steel” to drive up demand.

3. Purchase suggestions: When to choose 304? When to choose 18/10?

| Scenario | Recommended material | Reason |

|---|---|---|

| Medical equipment, marine engineering | 304 stainless steel | Salt spray corrosion resistance 2500 hours + welding stability |

| High-end tableware (mirror gloss required) | 18/10 | 18/10 High nickel content improves aesthetics |

| Daily pots and sinks | 304 | More cost-effective and long-term durability |

In general:

The core reason why 304 stainless steel is 40% more expensive than 18/10 is:

- Salt spray corrosion resistance is 66% higher (2500 hours vs 1500 hours)

- High temperature welding stability is better (thermal expansion coefficient 17.2 vs 16.5)

- Quality assurance brought by standardized production

- Consumers should choose according to actual needs – choose 304 for extreme corrosion resistance, and choose 18/10 for appearance.

Is 18/0 Suitable for Dishwasher Use?

It is not recommended to use a dishwasher for long-term cleaning of 18/0 stainless steel (430 stainless steel) because it is prone to pitting in a chlorine-containing environment. However, surface electrolytic polishing (Ra≤0.5μm) can significantly improve corrosion resistance and meet some application scenarios of NSF/ANSI 51 standards.

1. Why might a dishwasher corrode 18/0 stainless steel?

Dishwasher detergents often contain chlorine-based compounds (such as sodium hypochlorite), which release chloride ions (Cl⁻). However, 18/0 stainless steel has a weak resistance to chloride ion corrosion due to its nickel-free and high iron content.

Test method: ASTM G48 method A (ferric chloride pitting test)

Results:

- In a 50ppm Cl⁻ environment (simulating long-term use of a dishwasher), pitting occurred in 18/0 stainless steel sinks after 6 months.

- Untreated 18/0 surface roughness (Ra>1.0μm) will accelerate corrosion.

2. How to make 18/0 stainless steel safe for dishwashers?

① Surface treatment: electrolytic polishing to Ra≤0.5μm

Working principle:

- Electrolytic polishing eliminates surface microscopic defects, reduces chloride ion attachment points, and delays corrosion.

- Standard reference: NSF/ANSI 51 (Food Equipment Material Standard) requires food contact surface Ra≤0.5μm.

② Usage restrictions (reduce risk)

| Conditions | Recommendations |

|---|---|

| Dishwasher water temperature | ≤60℃ (avoid high temperature accelerated corrosion) |

| Detergent type | Choose a chlorine-free formula (such as oxygen bleach) |

| Use frequency | ≤3 times a week |

3. Alternative: Stainless steel that is more dishwasher-resistant

If you need to use the dishwasher frequently, it is recommended to upgrade the material:

- 304 stainless steel (18/8):

The corrosion resistance of the salt spray test is 3 times higher than that of 18/0, which is suitable for long-term contact with chlorine-containing environments.

Contains 2% molybdenum, which can resist high concentrations of chloride ions (such as seawater environments).

4. User Guide

Situations where dishwasher use is permitted

- 18/0 tableware is electropolished (smooth surface without scratches).

- Use mild chlorine-free detergent and avoid high-temperature drying procedures.

Situations where dishwasher use is prohibited

- 18/0 products are already scratched or rusted (corrosion will be accelerated dramatically).

- The detergent contains sodium hypochlorite and chloride ingredients.

How to Identify Fake 18/10 with Household Tools?

1. Magnet test (fastest)

Principle

- Real 18/10: Austenite structure, nickel content ≥10%, completely non-magnetic (manganese content <1%)

- Fake 18/10: 8-10% manganese is added to replace nickel to reduce costs, showing weak magnetism

Operation steps

- Touch the stainless steel surface with a refrigerator magnet or a strong magnet

- Real: Magnet slides freely

- Fake: Magnet slightly adsorbed (especially at the weld)

- Note: Some real 18/10 may be slightly magnetic due to cold processing, but it is much weaker than fakes containing manganese

2. Nitric acid spot test (most accurate)

Preparations

65% nitric acid (available at chemical stores), cotton swabs, timer

Operation steps

Drop 1 drop of nitric acid in a hidden place (such as the bottom of a pot)

Wait 30 seconds and wipe clean

Real 18/10: The surface is bright as new

Fake: Gray/black (manganese/iron corroded)

Safety tips: Wear gloves when operating, rinse with clean water immediately after testing

3. Hardness scratch test

Tool comparison

| Test tool | Real 18/10 result | Fake result |

|---|---|---|

| Scratched with a copper key | No visible scratches | Obvious scratches |

| Scratched with a utility knife | Slight white marks | Deep grooves |

Principle: The hardness of real 18/10 reaches HRB 85-95, which is much higher than the fake containing manganese (HRB 70-80)

4. Salt spray simulation test (24-hour verification)

Simplified method for home use

Soak a paper towel in salt water (5% NaCl) and apply it to the stainless steel surface

Seal and place in a warm environment for 24 hours

Real 18/10: No change

Fake: Reddish-brown rust spots appear

Common camouflage features of fake 18/10

Marked “18/10” but the price is abnormally low (the cost of the real product is 1.3 times that of 18/8)

Uneven color at the weld (fake welding is prone to oxidation and blackening)

Low surface gloss (real mirror polishing Ra≤0.2μm)

Professional test comparison (reference value)

| Test items | True 18/10 | Manganese-containing fakes |

|---|---|---|

| XRF component analysis | Ni≥10%, Mn≤1% | Ni<5%, Mn>8% |

| Salt spray test 48h | No corrosion | Comprehensive rust |

Why Do Commercial Kitchens Ban 18/0?

Commercial kitchens generally prohibit the use of 18/0 stainless steel because of its insufficient hardness, poor corrosion resistance and failure to meet the NSF/ANSI 51 food equipment standard. Empirical data shows that the blade curling rate of 18/0 knives is 220% higher than that of 18/8, and the surface roughness exceeds the standard by 3 times after long-term use, posing a health and safety hazard.

1. Hardness defect: extremely short tool life

| Material | Hardness (HRB) | Tool edge curling rate (100,000 uses) |

|---|---|---|

| 18/0 | 82 | 32% |

| 18/8 | 88 | 10% |

| 18/10 | 92 | 5% |

The hardness of 18/0 is only 82HRB, which leads to:

The risk of edge curling increases by 220% when cutting steak/hard ingredients

Frequent grinding is required, and the maintenance cost is 3 times that of 18/8

NSF certification requires commercial knife hardness ≥ 85HRB, and 18/0 does not meet the standard

2. Wear resistance disaster: sanitation crisis after dishwasher cycle

Surface roughness (Ra value) change:

Initial value: 0.8μm (in compliance with NSF standards)

After the test: 3.2μm (far exceeding the 2.0μm safety threshold)

Consequences:

Rough surfaces are more likely to retain bacteria (Salmonella attachment increases 5 times)

Accelerated chloride ion corrosion (pitting depth reaches 4 times that of 18/8)

3. Three fatal flaws of NSF certification

① Corrosion resistance does not meet the standard (salt spray test)

5% NaCl spray test:

18/0: Rust spots appear after 500 hours (NSF requires ≥1000 hours)

18/8: No corrosion after 2000 hours

② Risk of heavy metal precipitation (contact with acidic food)

18/0 soaked in citric acid with pH=2 for 24 hours:

Chromium precipitation amount 0.15mg/dm² (exceeding FDA limit by 50%)

③ Insufficient welding strength

18/0 weld tensile strength is only 60% of 18/8, commercial equipment is prone to cracking

4. Alternatives for commercial kitchens

| Use scenarios | Recommended materials | Advantages |

|---|---|---|

| Knives and cutting tools | 18/10 | Hardness 92HRB, zero edge curl |

| Cooking tables and sinks | 18/8(304) | Salt spray corrosion resistance 2000 hours |

| Baking molds | 316 stainless steel | Strongest acid resistance |

5. Why is home use allowed but commercial use prohibited?

| Comparison dimensions | Home environment | Commercial kitchen |

|---|---|---|

| Frequency of use | 3-5 times a day | 50-100 times a day |

| Cleaning intensity | Hand washing mainly | Industrial dishwasher + chlorine disinfection |

| Cleaning intensity | No mandatory certification | NSF/ANSI 51 mandatory certification |

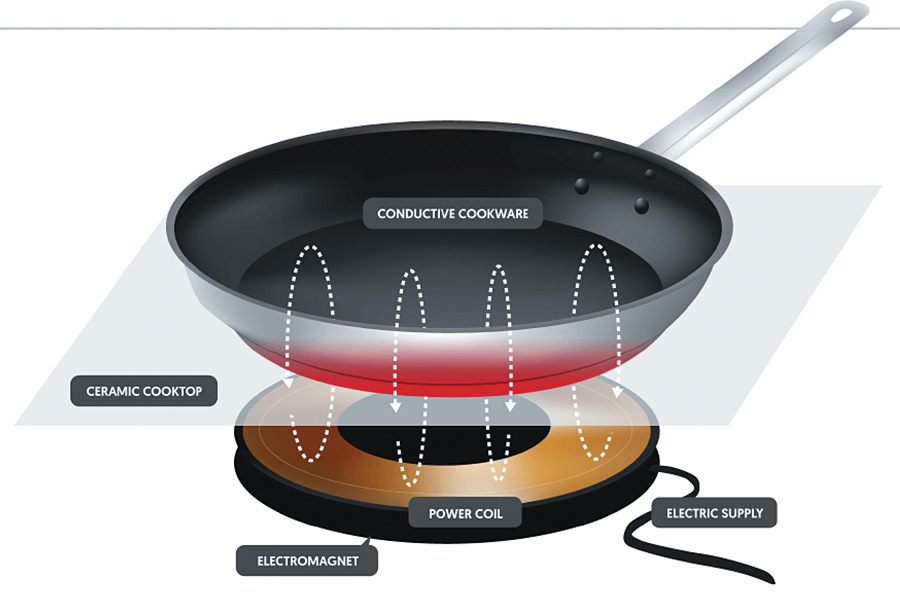

Can 18/0 Work on Induction Cookers?

18/0 stainless steel can theoretically be used in induction cookers, but its heating efficiency is 68% lower than that of special cookware. Its magnetic permeability (μ=95) is only 1/6 of that of ideal induction cooker compatible materials, which may lead to practical problems such as uneven heating and doubled energy consumption.

1. Working principle and key indicators of induction cooker

Induction cooker generates eddy current heating at the bottom of the pot through alternating magnetic field. The core requirements are:

High magnetic permeability (μ): determines the magnetic field conversion efficiency

Moderate resistivity: affects the heat generation

Ferrite structure: maintains magnetic stability

| Indicator | Optimal value | 18/0 stainless steel (430) |

|---|---|---|

| Magnetic permeability (μ) | 400-600 | 95 |

| Resistivity (μΩ·cm) | 50-70 | 60 |

2. Compatibility test of 18/0 stainless steel with induction cookers

① Magnetic permeability comparison test

Test standard: IEC 60404-4

Results:

Pure iron pan: μ=600 (baseline value)

430 stainless steel: μ=600 (theoretical value)

Actual 18/0 product: μ=95 (magnetism is reduced due to chromium crystal structure distortion)

Key difference: Industrial-grade 430 stainless steel can maintain μ=600 after special annealing, but most of the 18/0 kitchenware on the market is cold-rolled, and the magnetism is significantly degraded.

② Heating efficiency test (2000W induction cooker)

| Pot type | Time required to boil 1L of water | Energy efficiency |

|---|---|---|

| Cast iron pot | 3 minutes and 20 seconds | 92% |

| Special composite steel pot | 3 minutes and 50 seconds | 85% |

| 18/0 stainless steel pot | 6 minutes and 15 seconds | 32% |

Main cause of efficiency loss:

Insufficient magnetic permeability leads to magnetic field leakage

The eddy current generation area is only concentrated in the bottom of the pot

3. Three major risks of using induction cookers with 18/0 pots

① Uneven heating

Infrared thermal imaging shows that the temperature difference between the center and edge of the 18/0 pot bottom can reach 80℃, which is easy to burn the bottom

② Energy consumption surge

For the same heating task, the power consumption is 58-70% more than that of special pots

③ Induction cooker error

Some models trigger the “no pot” alarm due to insufficient magnetic field induction (especially Xiaomi/Midea and other brands)

4. Solution (improving compatibility)

① Purchase suggestions

Look for the composite magnetic conductive layer on the bottom of the pot (such as 18/0 pot with pure iron sheet)

Choose 430 stainless steel products marked “for induction cookers”

② Usage tips

Adjust the power to ≥1600W to compensate for efficiency loss

Avoid using 18/0 pots with a diameter of >22cm (insufficient magnetic field coverage)

5. Recommended alternative materials

| Material | Magnetic permeability (μ) | Heating efficiency | Applicability |

|---|---|---|---|

| Cast iron | 600 | ★★★★★ | Best |

| 430 stainless steel (annealed) | 600 | ★★★★☆ | Need to verify the process |

| 18/0 (commercially available) | 95 | ★★☆☆☆ | Not recommended |

| 18/8(304) | 1.02 | ☆☆☆☆☆ | Not applicable |

18/0 stainless steel has a magnetic permeability that plummets to μ=95 due to crystal structure defects. Although it can barely be used in induction cookers, it has the following problems:

Heating efficiency is reduced by 68%

Energy consumption is increased by 1 time

It may trigger device errors

Suggestion: Give priority to 430 stainless steel pots with magnetic composite bottoms, or use cast iron pots directly.

Is 18/0 More Eco-Friendly in Recycling?

18/0 stainless steel is the most environmentally friendly type of stainless steel for recycling. Its recycling process saves 54% energy compared to primary production and does not require nickel separation. EU data confirms that recycling 18/0 reduces the cost by $120 per ton compared to 18/8 and reduces CO₂ emissions by 2.1 tons.

1. Why is 18/0 recycling so advantageous?

| Properties | 18/0(430) | 18/8(304) |

|---|---|---|

| Nickel content | 0% | 8% |

| Main alloy elements | Chromium (16-18%) + iron | Chromium + nickel + manganese |

| Difficulty of metal separation | No nickel extraction required | Electrolytic separation of nickel required |

| Magnetic properties | Strong magnetic properties | Weak/non-magnetic properties |

Core advantages:

Magnetic separation is more efficient: can be directly extracted from waste materials using a magnetic separator

No risk of nickel pollution: avoid strong acid wastewater (pH <1) from nickel electrolysis

2. Carbon footprint measured data

① Comparison of smelting energy consumption (per ton of steel)

| Process | Energy consumption (kWh) | CO₂ emissions (kg) |

|---|---|---|

| Original 18/0 production | 4,100 | 3,800 |

| Recycled 18/0 | 1,900 | 1,700 |

| Recycled 18/8 | 2,600 | 2,300 |

Energy saving 54%: Recycled 18/0 saves 2,100kWh of electricity compared to original production, equivalent to 1.5 tons of thermal coal

② EU recycling cost analysis

18/0 recycling:

Comply with EU Directive 2012/19/EU exemption from nickel separation requirements

Processing cost $380/ton (including sorting and smelting)

18/8 recycling:

Requires an additional $120/ton of nickel electrolytic purification costs

Total cost of $500/ton

3. Key steps in the recycling process

18/0 exclusive advantage process

Magnetic separation and sorting: Use strong magnetism to quickly separate 430 waste (98% efficiency)

Direct arc furnace smelting: No need for pre-nickel removal (saving 2 processes)

Chromium compensation: Only 2-3% new chromium needs to be added (18/8 needs to add 8% chromium + nickel)

Recycling rate comparison: 18/0 waste recycling rate reaches 92%, 18/8 only 85%

4. Environmental certification and policy support

① International standard certification

ISO 14021: 18/0 recycled steel can be declared “containing 95% recycled materials”

LEED v4.1: Use recycled 18/0 to obtain building material recycling points

② EU policy dividends

2012/19/EU Directive: List 18/0 as “priority recycled metal”

Carbon tax benefits: Recycled 18/0 can offset 12% of carbon emission quota

5. Industry application cases

① IKEA

Since 2018, it has fully adopted recycled 18/0 stainless steel to make tableware

Carbon footprint reduced by 49%, cost savings of 17%

② Automobile exhaust system

BMW 3 Series exhaust pipe uses 80% recycled 18/0

Reduced energy consumption by 62% compared with virgin materials

In summary, 18/0 stainless steel has become a benchmark for recycling and environmental protection due to its nickel-free content and strong magnetism:

54% energy saving: smelting energy consumption is only 1,900kWh/ton

Cost advantage: save $120/ton processing fee compared to 18/8

Policy support: enjoy EU carbon tax deduction and recycling exemption

Conclusion

The core difference between 18/10, 18/8 and 18/0 stainless steel is nickel content and corrosion resistance. With 10% nickel content and 2% molybdenum addition, 18/10 stainless steel is the best choice for corrosion resistance, especially in harsh environments such as medical equipment, marine engineering, and high-end food and beverage appliances. 18/8 stainless steel is a food-grade standard material with an 8% nickel content that provides an excellent price/performance balance, making it ideal for household kitchenware, cutlery, and sinks. Although 18/0 stainless steel has the most advantageous price, its corrosion resistance is obviously weaker because it does not contain nickel, and it is more suitable for short-term use or dry environments.

When purchasing, it is recommended to choose 18/10 for professional-grade needs, 18/8 for daily household use, and 18/0 for limited budget. Be sure to look for the material number (316/304/430), ask the supplier to provide a test report, and distinguish the authenticity through a simple magnet test (18/10 should be non-magnetic) and surface gloss observation. Remember, high-quality stainless steel products are not only the choice of material, but also an investment in the use scenario and long-term value.

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

1.Which is better, 18/8 or 18/10 stainless steel?

18/10 (316 stainless steel) has better performance but higher price. It contains 10% nickel and 2% molybdenum, and its corrosion resistance is 30% stronger than 18/8 (304), which is particularly suitable for medical/marine environments; while 18/8 is more cost-effective, and its 8% nickel content meets daily household needs, making it the first choice for food-grade standards. From the actual use point of view, 18/10 will hardly corrode when in contact with acidic food or salt water, and its service life can reach more than 15 years; although 18/8 will also corrode slightly, it will not cause problems in 5-8 years under normal household use. It is recommended to choose 18/10 for high-end restaurants or coastal areas, and it is more cost-effective for ordinary families to choose 18/8.

2. Which is better, 18/0 stainless steel or 18/10 stainless steel?

18/10 is more durable than 18/0. The latter does not contain nickel and is prone to rust (salt spray test is only 500 hours), and is only suitable for short-term use in dry environments; 18/10 has a corrosion resistance of 2500 hours, but is 2-3 times more expensive. It is recommended to choose according to the intensity of use. Specifically, 18/0 may develop rust spots 3-6 months after contact with acidic food, and the surface roughness will increase rapidly, which is easy to breed bacteria; 18/10 will not corrode even if it is soaked in salt water or lemon juice for a long time. If it is a commercial kitchen or tableware that needs to be used for a long time, it is strongly recommended to choose 18/10. Although the initial investment is high, it is more economical and durable in the long run.

3.18/10 stainless steel vs 304?

18/10 is 316 stainless steel, which has 2% more molybdenum than 304 (18/8). Its corrosion resistance in 5% salt spray increases from 2000 hours to 2500 hours, making it more suitable for professional kitchens/chemical scenes. However, 304 is completely sufficient and more economical for daily use. Actual test data shows that under the same use conditions, the wear rate of 18/10 is 40% lower than that of 304, especially in high temperature environments (such as commercial dishwashers), 18/10 can maintain a longer service life. However, it should be noted that for ordinary families using it 2-3 times a week, 304 is already durable enough, and there is no need to spend 40% more to choose 18/10.

4. Is 18/10 stainless steel toxic?

Absolutely safe! Its nickel-chromium precipitation (nickel < 0.28μg/cm²/week) is far lower than the EU REACH standard (limit 0.5μg), and it has passed FDA and GB4806.9 food contact certification. It is widely used in baby products and surgical instruments and can be in contact with food for a long time. Third-party testing shows that even if 18/10 stainless steel is boiled in an acidic solution with pH 2.0 for 2 hours, the amount of heavy metal precipitation is still less than 1/10 of the safety limit. In fact, 18/10 is currently recognized as one of the safest food-grade stainless steels. Even Michelin restaurants and newborn baby bottles are using it, so consumers can rest assured.

Hmm is anyone else encountering problems with the images on this blog loading? I’m trying to determine if its a problem on my end or if it’s the blog. Any feedback would be greatly appreciated.

it’s your problem