Over the previous few many years, 3D printing know-how has undergone speedy growth. It has not solely modified the best way we manufacture objects but in addition expanded the boundaries of design, turning the not possible into attainable. The importance of this know-how is self-evident, showcasing great potential and worth throughout numerous fields comparable to medication, aviation, and development.

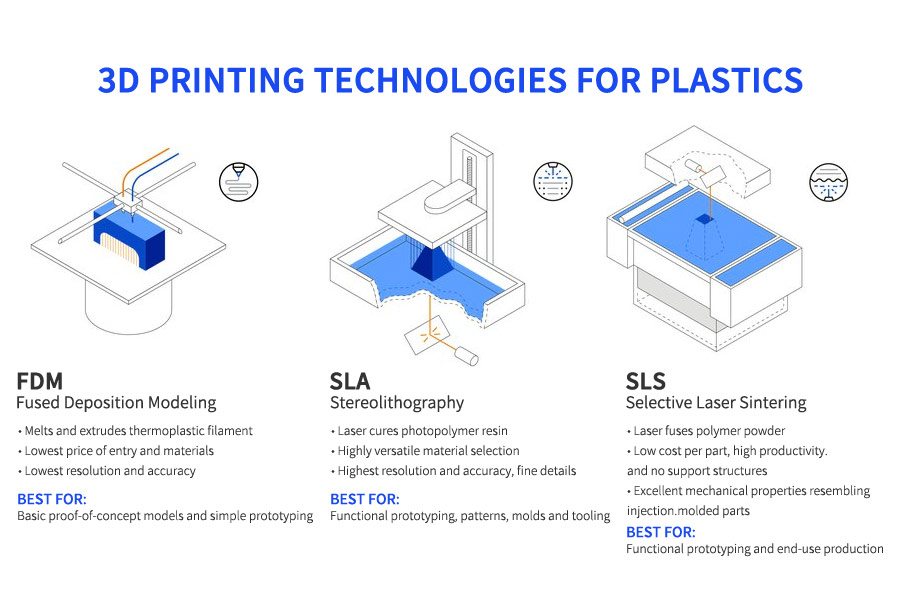

Among the many quite a few 3D printing applied sciences, SLA (Stereolithography), PolyJet, and SLS (Selective Laser Sintering) have emerged because the three mainstream applied sciences within the industry due to their unique printing principles and material dealing with strategies. This text will delve into the working principles, benefits, and downsides of those applied sciences, in addition to their purposes in numerous fields, aiming to offer readers with a transparent comparative perspective.

What’s SLA?

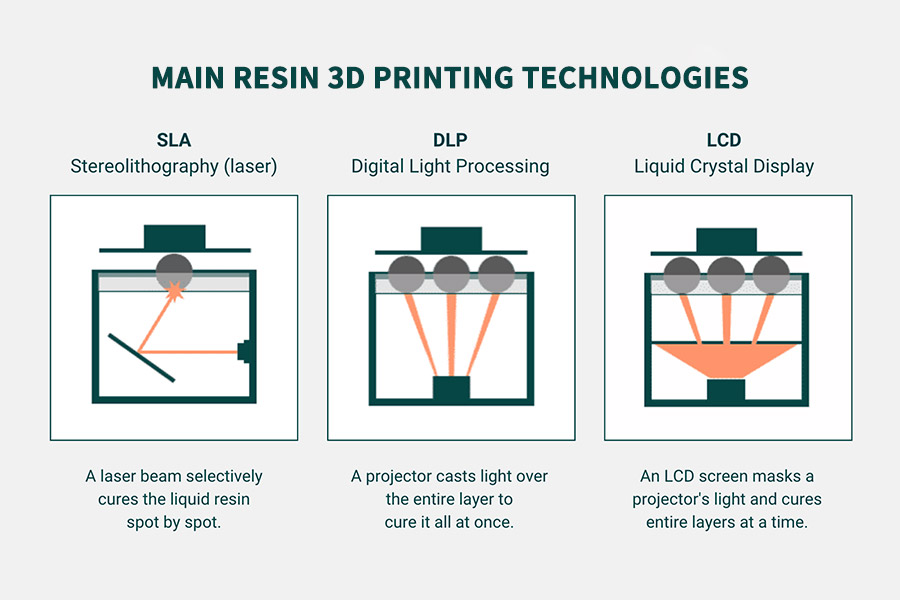

SLA know-how includes utilizing an ultraviolet laser to scan over a vat of liquid photopolymer, solidifying the resin layer by layer. This process is repeated till the whole mannequin is constructed. SLA technology involves a laser beam scanning over the surface of a liquid photosensitive resin, layer by layer, inflicting the resin to solidify and form. Think about utilizing a laser pen to attract on jelly; wherever it touches, it hardens, ultimately making a three-dimensional mannequin.What’s PolyJet?

PolyJet technology works by jetting microscopic droplets of photopolymers onto a construct platform and instantly curing them with ultraviolet gentle. This know-how can use a number of varieties of resins concurrently, permitting for the printing of multi-color or multi-material composite fashions. PolyJet know-how works like a printer, ejecting photopolymer materials onto a construct platform after which instantly curing it with ultraviolet gentle. This process is repeated, layer by layer, like making a cake, stacking up one layer at a time to form complicated fashions.

What’s SLS ?

SLS technology uses powder material, with a laser scanning every layer in keeping with slice knowledge, melting or sintering the powder right into a stable layer. Since every layer of powder helps the one above it, fashions printed with SLS don’t require extra assist buildings. SLS know-how makes use of a laser to sinter (warmth to only beneath the melting level) powdered materials, inflicting the powder particles to bond collectively. It is like utilizing a laser pen to attract on a pile of sand; the grains are heated after which stick collectively, progressively forming the mannequin you need.

SLA VS PolyJet VS SLS

| Expertise | Advantages | Disadvantages |

|---|---|---|

| SLA | Excessive precision, {smooth} floor, good element | Restricted materials decisions, a number of post-processing steps |

| PolyJet | Can print in a number of colours and materials, excessive precision | Increased price, slower printing speed compared to SLS |

| SLS | Excessive materials power, no want for assist buildings, appropriate for batch manufacturing | Rough surface, restricted coloration decisions |

Software Fields of SLA Expertise:

- Jewellery Design: As a consequence of its capacity to print high-precision and smooth-surfaced fashions, SLA is especially appropriate for creating complicated jewellery prototypes.

- Dental and Medical: The precision of SLA printing is apt for producing dental fashions, surgical guides, and different medical instruments.

- Prototyping and Mannequin Making: SLA is the ideal choice for creating detailed prototypes and fashions of artworks.

Software Fields of PolyJet Expertise:

- Multi-Materials and Shade Merchandise: PolyJet can print in a number of colours and materials, making it appropriate for creating complicated prototypes of shopper items.

- Schooling and Analysis: As a consequence of its variety in colours and materials, PolyJet is commonly used for mannequin making in instructing and scientific analysis.

- Design Verification: Designers can use PolyJet to rapidly confirm the looks and really feel of product designs.

Software Fields of SLS Expertise:

- Industrial Parts: SLS-printed parts are excessive in power, making them appropriate for manufacturing purposeful industrial components.

- Automotive Industry: SLS is often used for speedy prototyping and small-batch manufacturing of automotive parts.

- Aerospace: As a consequence of its excessive power and sturdiness, SLS know-how can also be extensively used within the aerospace field.

Materials Compatibility:

- SLA: Primarily appropriate with quite a lot of photosensitive resins, providing totally different mechanical and thermal properties.

- PolyJet: Able to utilizing a number of materials together with clear, versatile, inflexible, or biocompatible materials, and may combine them to create multi-color or multi-material fashions.

- SLS: Primarily makes use of thermoplastic powders like nylon, with fewer choices, however appropriate for functional parts.

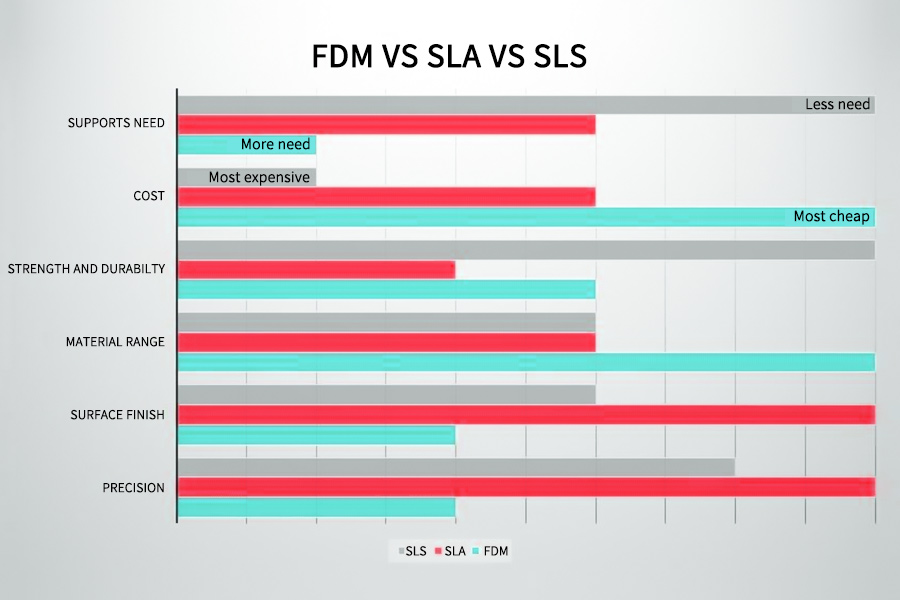

Printing Precision and Floor End:

- SLA: Excessive precision, {smooth} floor, good element illustration, however might require post-processing to take away assist buildings.

- PolyJet: Extraordinarily excessive precision, {smooth} floor, virtually no post-processing wanted, appropriate for complicated fashions and positive particulars.

- SLS: Average precision, barely rough surface, often doesn’t require assist buildings, decreasing post-processing work.

Manufacturing Pace and Value:

- SLA: Slower pace, price will increase with print quantity, appropriate for small batches or products requiring excessive precision.

- PolyJet: Quick pace, however materials and tools prices are greater, appropriate for high-quality prototype production.

- SLS: Average pace, comparatively lower cost, particularly cheaper when printing in massive portions.

Publish-Processing Wants:

- SLA: Requires cleansing and curing, and may have sanding and portray.

- PolyJet: Wants water jetting to take away assist materials, however typically less complicated than SLA.

- SLS: Must take away un-sintered powder, typically adopted by sanding or dyeing.

Components to Take into account When Selecting the Proper Expertise:

- Objective of Printing: Is it for prototype design, inventive creation, or functional parts?

- Materials Necessities: What properties do you want from the fabric? Comparable to power, flexibility, or warmth resistance.

- Precision Wants: How detailed and exact does your mannequin have to be?

- Price range Constraints: What’s your finances vary? Prices can range considerably between applied sciences.

- Publish-Processing Time: How a lot time are you able to put money into post-processing the mannequin?

Future Traits:

- Automation and Intelligence: Future 3D printing applied sciences will turn out to be extra automated, decreasing the necessity for handbook intervention.

- Materials Innovation: The event of latest materials will expand the applications of 3D printing.

- Eco-Friendliness: Eco-friendly materials and recyclability will turn out to be a spotlight of analysis and growth.

- Practical Integration: Printed parts may have extra built-in capabilities, comparable to embedded circuits or sensors.

LongSheng, a 3D printing provider, can present numerous 3D printing companies, together with SLA, PolyJet, and SLS applied sciences.

-

SLA (Stereolithography):

- LongSheng offers high-precision SLA printing services appropriate for fashions requiring positive surfaces and complex particulars.

- LongSheng will make it easier to select the appropriate photosensitive resin material and supply post-processing companies comparable to cleansing, curing, and coloring.

-

PolyJet Expertise:

- LongSheng’s PolyJet service can print multi-material and multi-color fashions, excellent for prototypes and visible fashions.

- They provide a variety of fabric decisions and be sure that the printed fashions have {smooth} surfaces and exact particulars.

-

SLS (Selective Laser Sintering):

- LongSheng’s SLS printing services are suitable for producing functional parts, particularly people who require sturdiness and power.

- LongSheng will help you in selecting the very best thermoplastic powder materials and supply obligatory post-processing, comparable to sanding and dyeing.

This was beautiful Admin. Thank you for your reflections.