It’s worth noting that CNC machining can also be used in conjunction with 3D printing. For example, you could 3D print a part with a rough shape and then use CNC machining to refine the details and achieve a higher level of precision. This approach can help to save time and reduce material costs compared to fully machining a part from scratch.

What is 3D printing service?

3D printing service is a process of creating three-dimensional objects from a digital file using a 3D printer. The 3D printer uses different materials, such as plastic, metal, and ceramics, to build the object layer by layer based on the design specifications. This service is useful for creating prototypes, models, and custom parts for various industries, including automotive, aerospace, healthcare, and education. 3D printing service is becoming more popular due to its cost-effectiveness, speed, and precision compared to traditional manufacturing methods.

How much does a 3D printing job cost?

The cost of a 3D printing job varies depending on several factors such as material, complexity, size, and quantity. Materials can range from inexpensive plastics to more expensive metals and composites. Simple designs with fewer details and smaller sizes are generally less expensive than complex designs with intricate details and larger sizes.

In addition to these factors, the cost of a 3D printing job may also include setup fees, post-processing, and shipping charges. Some 3D printing services charge a flat fee per job, while others charge based on the weight of the final product.

To get an accurate estimate on the cost of a 3D printing job, it is best to contact a 3D printing service provider and provide them with the necessary details about the project. They can then provide a quote based on the specific requirements of the job.

Overall, the cost of a 3D printing job can range from a few dollars to hundreds or even thousands of dollars, depending on the factors mentioned above.

When To CNC Machine Your 3D Printed Parts

If you are looking to create complex geometries or parts that require high strength and durability, 3D printing can be an excellent choice. However, there are certain scenarios when it makes sense to use CNC machining to finish or modify your 3D printed parts.

Here are some common situations when you might want to consider CNC machining your 3D printed parts:

1. Tight Tolerances

While 3D printing has come a long way in terms of accuracy, it can still be challenging to achieve very tight tolerances. CNC machining can be a great way to achieve the level of precision you need for your part.

2. Post-Processing

3D printed parts often require post-processing to remove support material, smooth rough surfaces, or add additional features. CNC machining can be a more efficient way to accomplish these tasks than doing them by hand.

3. Material Selection

While 3D printing offers a wide range of materials to choose from, some applications may require a material that is not available in a printable form. In these cases, CNC machining can be used to create a part from a material that is not available for 3D printing.

4. Strength and Durability

While 3D printing can produce strong parts, the strength and durability of the part can be increased through CNC machining. Machining can help to remove weak points in the part and create a more solid and robust structure.

In conclusion, while 3D printing can be an excellent choice for many applications, there are scenarios when CNC machining can provide additional benefits. If you need tight tolerances, post-processing, unique materials, or increased strength and durability, CNC machining may be the right choice for your 3D printed parts.

Can 3D printed parts be machined?

Yes, 3D printed parts can be machined. While 3D printing technology has come a long way, there are still limitations on the accuracy and surface finish of 3D printed parts. Machining can be used to improve these qualities to achieve a higher level of precision in the final product.

It is important to note that the type of 3D printing process used will affect the machinability of the part. For example, parts printed using Fused Deposition Modeling (FDM) technology may have a rougher surface finish and may require more machining to achieve the desired result.

Additionally, the material used in 3D printing will also impact the machinability of the part. Certain materials such as ABS and Nylon are more easily machined than others like PLA and PETG.

Overall, while 3D printing can be a cost-effective and efficient way to produce parts, machining is often necessary to achieve the level of precision required for many applications.

Can you CNC 3D printed parts?

Yes, it is possible to CNC 3D printed parts. CNC (Computer Numerical Control) machines are capable of cutting and shaping various materials, including plastics like those commonly used in 3D printing

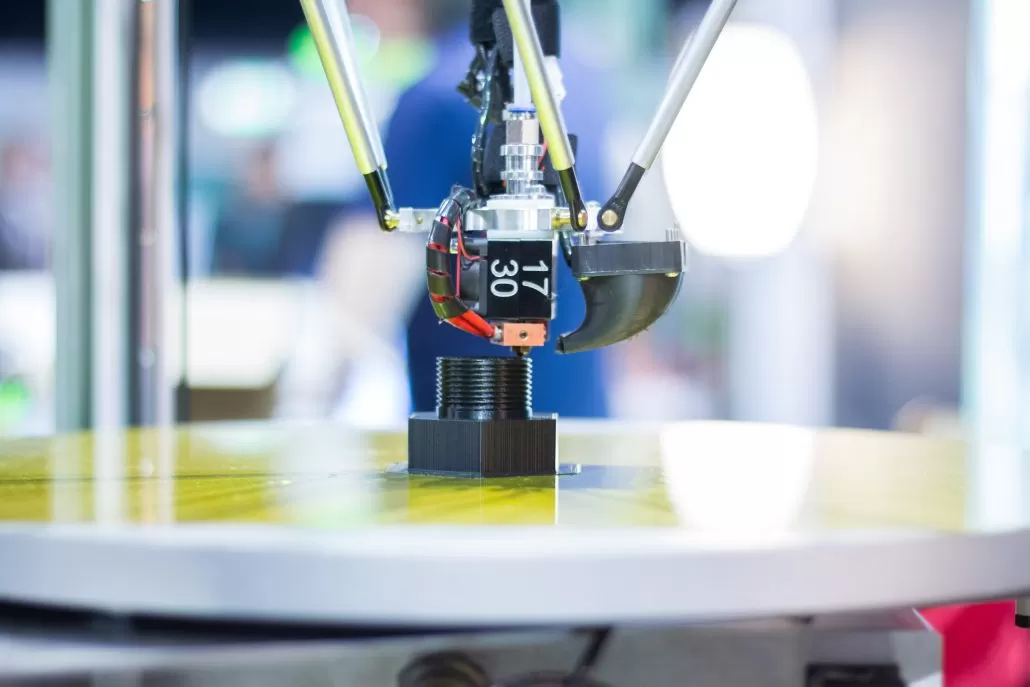

CNC machining is a subtractive manufacturing process that uses pre-programmed computer software to control the movement of cutting tools and machinery. This allows for precise and accurate cutting and shaping of materials, which makes it an ideal process for creating complex geometries and intricate designs.

While 3D printing and CNC machining share some similarities, such as their ability to produce parts with complex geometries, they also have some notable differences. 3D printing is an additive manufacturing process that builds parts layer by layer, while CNC machining removes material from a solid block of material.

It is important to note that the level of precision and detail achieved through CNC machining may differ from that of 3D printing. Additionally, the material properties may also change due to the heat generated during CNC machining. Therefore, it is important to consider the specific requirements of the part before deciding to CNC a 3D printed piece.

Overall, CNC machining can be a useful process for refining and finishing 3D printed parts, especially for those that require tight tolerances or a high level of accuracy. However, it is important to consider the limitations and potential changes to material properties before deciding to CNC a 3D printed part.

Is CNC machining better than 3D printing?

When it comes to manufacturing, both CNC turning parts machining and 3D printing have their own unique set of advantages and disadvantages. CNC machining is a subtractive manufacturing process that uses pre-programmed computer software to control the movement of machinery and tools. On the other hand, 3D printing is an additive manufacturing process that involves building up layers of material to create a final product.

CNC machining is ideal for high volume production runs, as it can produce large quantities of parts quickly and accurately. It is also capable of working with a wide range of materials, including metals, plastics, and composites. CNC machining also produces parts with excellent surface finishes and dimensional accuracy.

On the other hand, 3D printing is ideal for small production runs and prototyping. It is a very flexible manufacturing process that allows for the production of complex geometries that would be difficult or impossible to produce with CNC machining. 3D printing also allows for the production of parts with internal cavities and complex shapes.

Ultimately, whether CNC machining or 3D printing is better depends on the specific needs of the project. CNC machining is better suited for high volume production runs, while 3D printing is better suited for small production runs and prototyping.

What would be some advantages of CNC over 3D printing?

CNC (Computer Numerical Control) and 3D printing are both modern manufacturing techniques used to create complex parts with precision. However, there are some advantages that CNC has over 3D printing.

- Material selection: CNC can work with a wide range of materials, including metals, plastics, and composites, whereas 3D printing is limited to certain types of plastics and resins.

- Strength and durability: Parts made with CNC are generally stronger and more durable than those made with 3D printing due to the higher density and quality of the materials used.

- Surface finish: CNC can produce parts with a smoother surface finish than 3D printing, which can often have visible layer lines and surface imperfections.

- Speed: CNC is generally faster than 3D printing for producing large quantities of parts, as it can create multiple parts simultaneously and does not require time for layer-by-layer printing.

- Precision: CNC can produce parts with higher precision and accuracy than 3D printing, especially for complex geometries and tight tolerances.

Overall, while 3D printing is a useful tool for rapid prototyping and small-scale production, CNC offers a wider range of material options, stronger and more durable parts, smoother surface finishes, faster production times for large quantities, and higher precision for complex geometries and tight tolerances.