As technology advances, the manufacturing industry has seen a significant shift towards the use of 3D printing and CNC machining. Both of these methods have their advantages and disadvantages, and knowing when to switch from 3D printing to CNC machining can be a difficult decision to make.This article explores the benefits and drawbacks of using 3D printing and CNC machining in the manufacturing industry. It examines the strengths and weaknesses of each method and provides guidance on when to switch from 3D printing to CNC machining or vice versa.

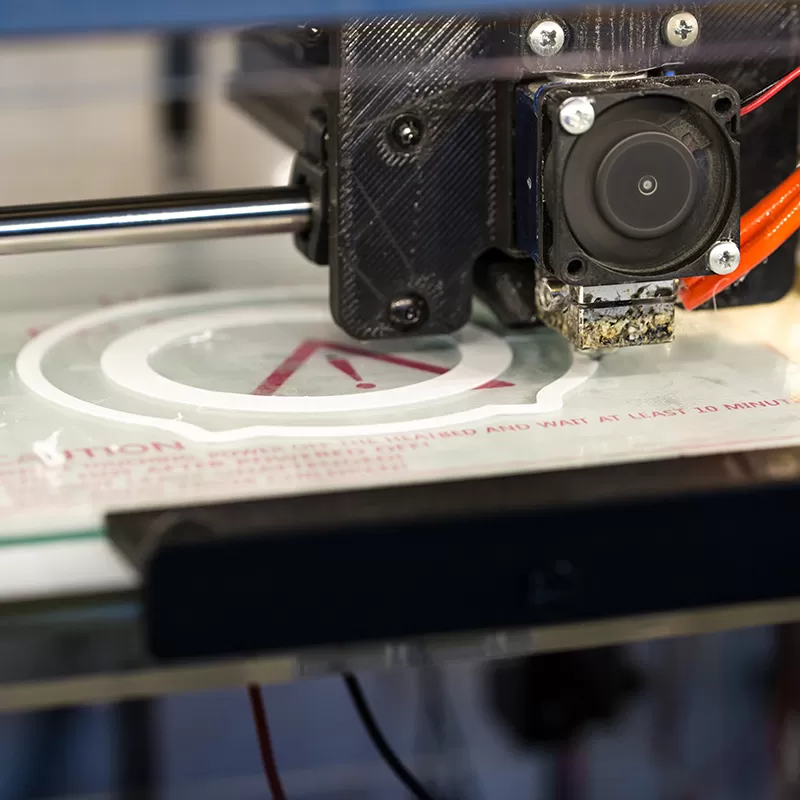

3D printing is a process that creates a three-dimensional object from a digital model by laying down successive layers of material until the object is complete. It is ideal for rapid prototyping and small production runs, as it is quick and cost-effective. It allows for complex designs to be created with ease and has a relatively low setup cost. However, the quality of the final product is often not as high as that produced by CNC machining, and the materials used may not be as durable.

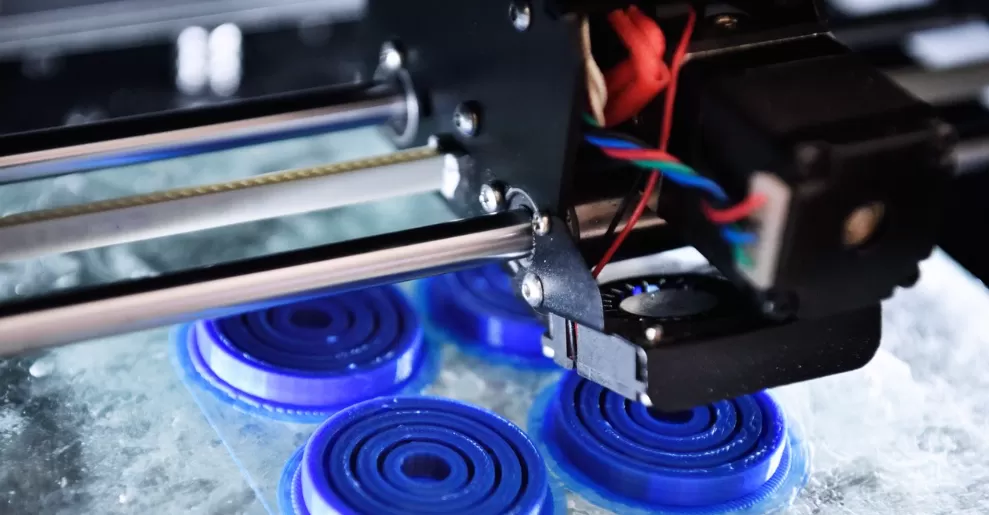

On the other hand, CNC machining is a subtractive manufacturing process that removes material from a solid block of material to create a final product. It is better suited for larger production runs and creating high-quality, durable products. It can produce complex designs with a high degree of accuracy and precision, and the final product is often stronger and more reliable than that produced by 3D printing. However, CNC machining requires a higher setup cost and can be time-consuming.

For instance, 3D printing is more suitable for products that don’t require high levels of strength or durability. If you are looking to produce a product that is not subjected to high-intensity usage, then 3D printing may be the best option for you. 3D printing is also great for creating customized objects, as it allows for the creation of unique shapes and designs that may not be possible with CNC machining.

CNC machining, on the other hand, is better suited for larger production runs that require a higher level of accuracy and precision. It is also ideal for creating objects made from materials that require high strength and durability, such as metal or carbon fiber. CNC machining can produce parts that are stronger and more reliable than parts created by 3D printing, making it the better option for products that require high-intensity usage.

So, when should you switch from 3D printing to CNC machining? The answer depends on your specific needs and requirements. If you are creating a small batch of products or need a quick prototype, 3D printing may be the best option. However, if you require a high-quality, durable product or are producing a larger quantity, CNC machining may be the better choice.

Ultimately, the decision to switch from 3D printing to CNC machining should be based on a careful consideration of your needs, budget, and timeline. Both methods have their strengths and weaknesses, and choosing the right one for your project can make all the difference in the success of your manufacturing process.

In summary, 3D printing and CNC machining are both valuable tools in the manufacturing industry, and each has its place in the production process. By understanding the strengths and weaknesses of each method, you can make an informed decision about when to switch from 3D printing to CNC machining and vice versa.