This article discusses the ongoing debate surrounding the use of 3D printing and CNC machining in rapid prototyping. While both technologies have their strengths and weaknesses, it is unlikely that 3D printing will completely replace CNC machining anytime soon. In fact, many rapid prototyping companies use both technologies in tandem to produce high-quality parts quickly and efficiently.

Will 3D Printing Replace CNC Machining Rapid Prototyping?

The world of rapid prototyping has been evolving rapidly over the past few years. With the advent of 3D printing technology, there has been a lot of debate about whether it will replace CNC machining in rapid prototyping.

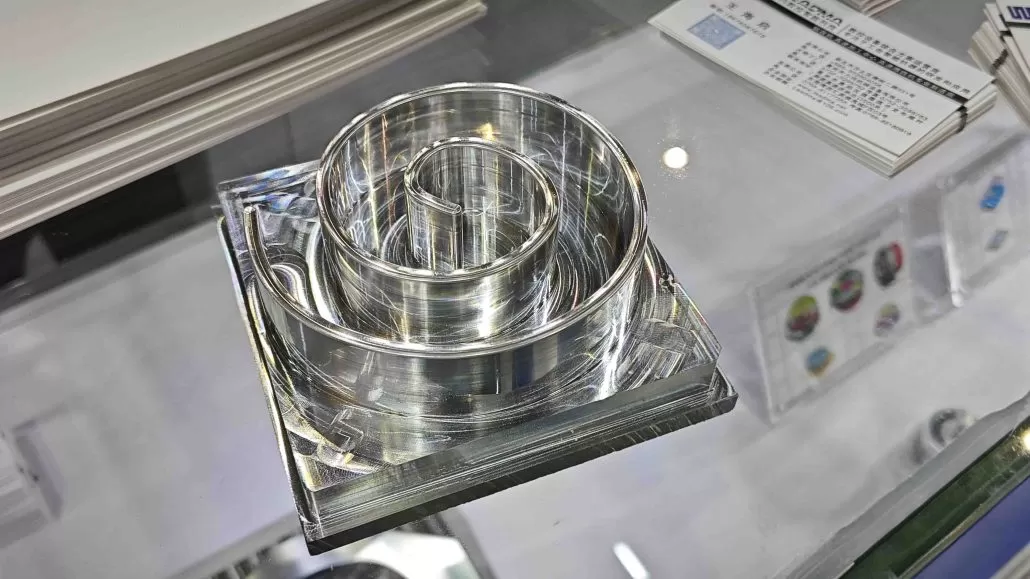

To answer this question, we need to look at the strengths and weaknesses of both technologies. CNC machines are great for producing high precision parts with very tight tolerances. They are also great for producing large quantities of parts quickly. However, they are limited by their ability to produce complex shapes.

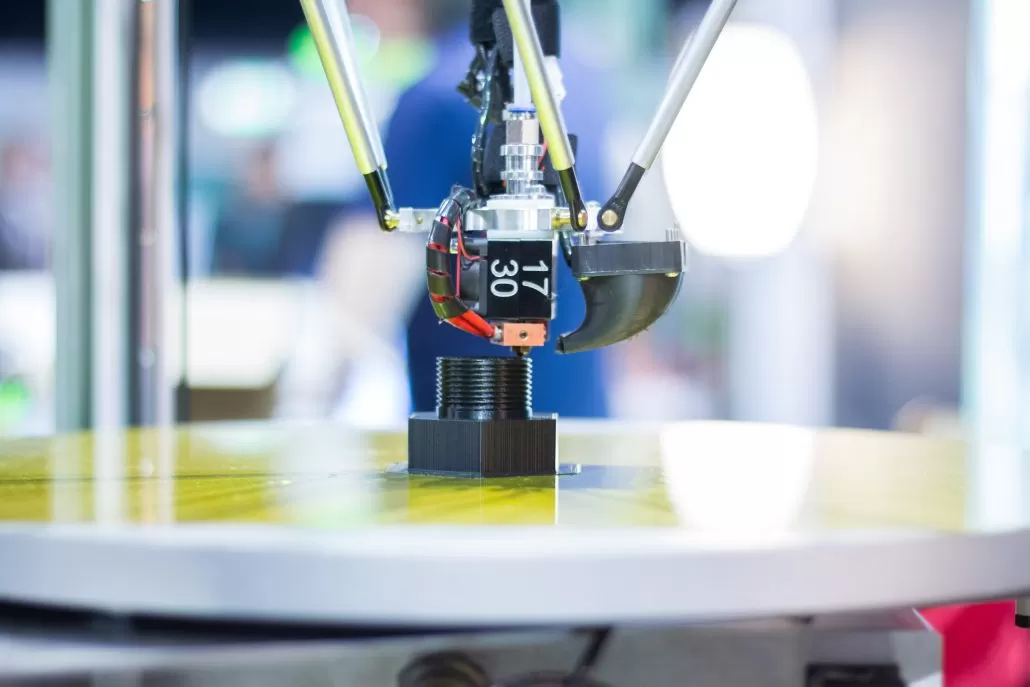

3D printing service, on the other hand, is great for producing complex shapes with ease. It is also great for producing small quantities of parts quickly. However, it is limited by its ability to produce parts with high precision and tight tolerances.

So, to answer the question, it is unlikely that 3D printing will completely replace CNC machining in rapid prototyping. Both technologies have their strengths and weaknesses, and are best suited for different types of parts and projects. In fact, many rapid prototyping companies use both technologies in tandem to produce high-quality parts quickly and efficiently.

In conclusion, while 3D printing has certainly revolutionized the world of rapid prototyping, it is unlikely that it will completely replace CNC machining anytime soon. Both technologies have their place in the world of rapid prototyping and will continue to coexist for the foreseeable future.

CNC Machining and 3D Printing: Which is Better?

In the field of rapid prototyping, there have been many changes in recent years. With the emergence of 3D printing technology, there has been a lot of debate about whether it will replace CNC machining.

To answer this question, we need to look at the strengths and weaknesses of both technologies. CNC machines are great for producing high precision parts with very tight tolerances. They are also great for producing large quantities of parts quickly. However, they are limited by their ability to produce complex shapes.

On the other hand, 3D printing is great for producing complex shapes with ease. It is also great for producing small quantities of parts quickly. However, it is limited by its ability to produce parts with high precision and tight tolerances.

Therefore, we need to understand the advantages and disadvantages of each technology in order to make wise decisions when choosing between them. CNC machining is a traditional method that uses precision automated machine tools to cut materials and manufacture the required parts. It uses highly accurate tools and techniques to produce high-quality parts. However, the main disadvantage of CNC machining is that it requires the manufacture of cutting tools, which may take longer and cost more. Additionally, CNC machining typically requires more post-processing and Surface Finishing Services work to perfect the quality of the part surface.

3D printing is a relatively new method that uses a computer to control the printer to print the required parts. It can produce complex geometric shapes that traditional CNC machining cannot achieve. Additionally, 3D printing does not require the manufacture of cutting tools, so it can produce the required parts more quickly and allow for more design changes during the production process. However, the main disadvantage of 3D printing is that the parts it produces typically have lower precision and strength, and it takes longer to produce large quantities of parts.

Overall, CNC machining and 3D printing both have their advantages and disadvantages, and may be more suitable in different situations. When making decisions, we need to consider the applicability of each technology based on factors such as the type, quantity, quality, and time required for the parts. In fact, many rapid prototyping companies use both CNC machining and 3D printing technologies simultaneously to meet the different needs of their customers. Therefore, there is no one technology that is better than the other, and it is important to make wise choices based on the actual situation.

CNC Machining and 3D Printing: Which is Cheaper?

In the field of rapid prototyping, both CNC machining and 3D printing have their advantages and disadvantages. Cost is an important factor to consider when choosing which technology to use.

CNC machining typically requires expensive machines and tools, and a significant amount of post-processing and finishing work. These costs can affect the final price of the product. However, CNC machining services can usually produce more precise and higher quality parts.

3D printing typically requires less equipment and material costs, making it more cost-effective for small-scale production. However, 3D printing typically requires longer production times and may have more limited options for part quality and material selection.

Therefore, cost considerations must be weighed alongside other factors. Before using CNC machining or 3D printing, the size, shape, quantity, and quality requirements of the parts must be taken into account. In practice, it may be necessary to use both CNC machining and 3D printing simultaneously to meet different requirements.

Overall, the choice between CNC machining and 3D printing depends on the specific situation. While 3D printing is typically cheaper, in some cases CNC machining may be more suitable. Therefore, various factors such as cost, quality, speed, and availability must be considered when making a choice.

Is 3D Printing Suitable for Rapid Prototyping?

3D printing is an excellent technology for rapid prototyping. It allows designers and engineers to create physical models of their designs quickly and affordably. With 3D printing, you can produce a prototype in a matter of hours or days, whereas traditional manufacturing methods can take weeks or even months.

One of the biggest advantages of 3D printing for rapid prototyping is its flexibility. You can easily make changes to your design and print a new prototype in a matter of hours. This allows for a more iterative design process, which can lead to better overall designs.

Another advantage of 3D printing for rapid prototyping is its cost-effectiveness. Traditional manufacturing methods require expensive tooling and setup costs, which can be a significant barrier to entry for small businesses and startups. 3D printing, on the other hand, requires little to no tooling and setup costs, making it much more accessible.

Overall, 3D printing is an excellent technology for rapid prototyping. It allows designers and engineers to quickly and affordably create physical models of their designs, iterate on those designs, and ultimately create better products.

Advantages of 3D printing over CNC

There are several advantages of 3D printing over CNC:

- Design Flexibility: 3D printing allows for greater design flexibility because it allows for the creation of complex geometries that would be difficult, if not impossible, to achieve with CNC machining.

- Lower Cost: 3D printing is generally less expensive than CNC machining, particularly for small production runs. 3D printing also eliminates the need for expensive tooling, which can be a significant cost savings.

- Faster Turnaround: 3D printing generally has faster turnaround times than CNC machining, particularly for small production runs. 3D printing also allows for rapid prototyping, which can speed up the product development process.

- Material Efficiency: 3D printing is a more material-efficient process than CNC machining because it only uses the exact amount of material needed to create a part. CNC machining, on the other hand, typically results in a significant amount of material waste.

- Customization: 3D printing allows for greater customization because each part can be easily customized without the need for expensive tooling or reprogramming.

Overall, 3D printing has several advantages over CNC machining, particularly for small production runs and complex geometries.

n conclusion, while the emergence of 3D printing has certainly revolutionized rapid prototyping, it is important to consider the advantages and disadvantages of each technology in order to make informed decisions when choosing between them.

Overall, the choice between CNC machining and 3D printing depends on various factors such as cost, quality, speed, and availability. By understanding the strengths and limitations of each technology, we can make informed decisions and use both technologies in tandem to produce high-quality parts quickly and efficiently.

FAQ

CNC machining is more suitable for producing large quantities of parts due to its ability to produce a large number of parts in a shorter period of time, and the high precision and quality of the parts produced by CNC machining. However, 3D printing is better suited for producing smaller quantities of parts due to its slower production speed.

The quality of parts produced by 3D printing is generally lower than that of parts produced by CNC machining because 3D printed parts usually have lower precision and strength. Additionally, the surface of 3D printed parts usually requires post-processing and finishing work in order to achieve the desired surface quality.

3D printing is generally cheaper than CNC machining due to its lower equipment and material costs. However, 3D printing typically takes longer to produce parts than CNC machining, and the quality and material options of 3D printed parts may also be more limited.

3D printing is better suited for producing complex parts because it can easily produce parts with a variety of shapes. CNC machining is typically not able to produce complex shapes because its tools cannot reach certain angles and positions.

When choosing between 3D printing and CNC machining, many factors should be considered, including the size, shape, quantity, and quality requirements of the parts, as well as equipment and material costs, production time, and post-processing work. Typically, both 3D printing and CNC machining technologies are used simultaneously to meet different needs.