In recent years, 5-axis CNC has been increasingly widely used in various fields. In practical applications, whenever people encounter difficulties in efficient and high-quality machining of complex and irregular parts, the 5 axis linkage technology is undoubtedly an important means to solve such problems.

But many people generally believe that 5-axis CNC machining technology is the only means to process continuous, smooth, and complex surfaces. Once encountering unsolvable problems in the design and manufacturing of complex surfaces, they will turn to 5-axis machining technology.

However, 5-axis linkage CNC is the most difficult and widely used technology in CNC technology. It integrates computer control, high-performance servo drive, and precision machining technology, and is applied to efficient, precise, and automated machining of complex surfaces.

Internationally, 5-axis linkage CNC technology is regarded as a symbol of a country’s production equipment automation technology level. Due to its special status, especially its significant impact on aviation, aerospace, and military industries, as well as its technological complexity, Western industrialized countries have always implemented an export license system for 5-axis CNC systems as strategic materials.

What Is 5-Axis CNC Machining

5-axis machining is a mode of CNC machining.

The commonly referred to 5 axis linkage refers to linear interpolation motion performed by selecting any 5 coordinates from the coordinate axes X, Y, Z, A, and B. In other words, 5-axis refers to the three moving axes x, y, and Z plus any two rotating axes. When machining complex geometric parts, 5-axis machining is a machining method. Compared to common 3-axis machining, 5-axis machining requires the tool to be able to position and connect on 5 degrees of freedom.

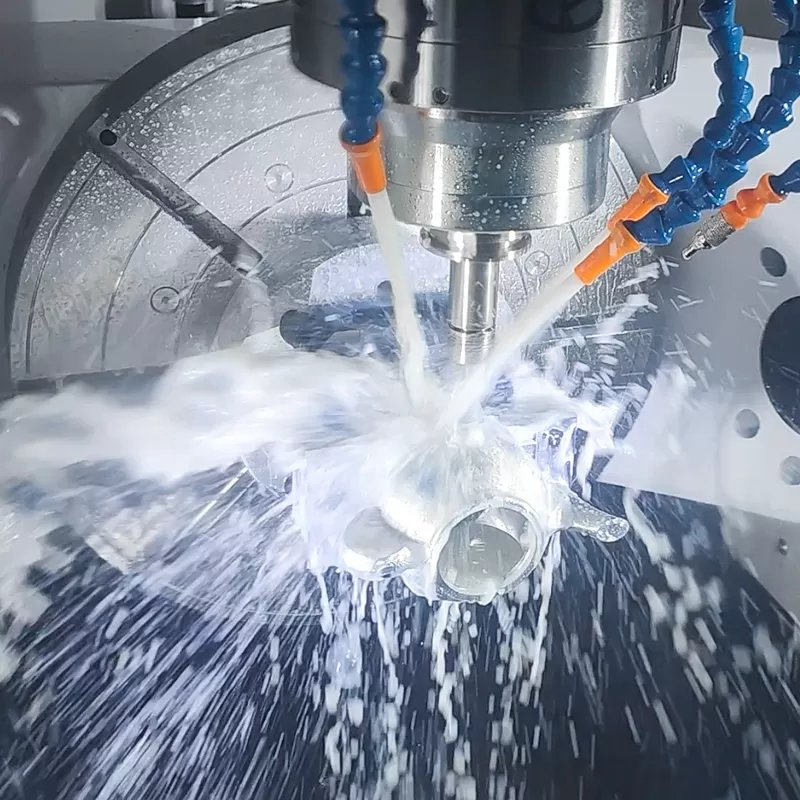

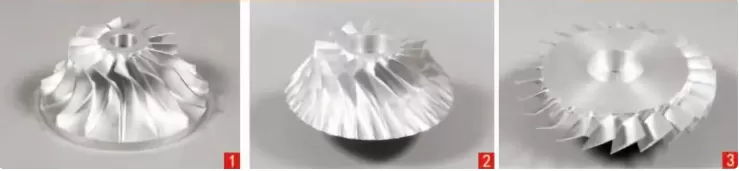

Machine tools used for 5 axis machining are generally referred to as 5 axis machine tools or 5 axis machining centers. 5 axis machining is mainly used in the aerospace field for machining fuselage components with complex surfaces, turbine components, and impellers. Using a 5 axis machine tool, different sides of the workpiece can be machined without moving the workpiece position. This method can significantly improve the efficiency of processing prismatic parts.

Mechanical structure form of 5-axis machine tool

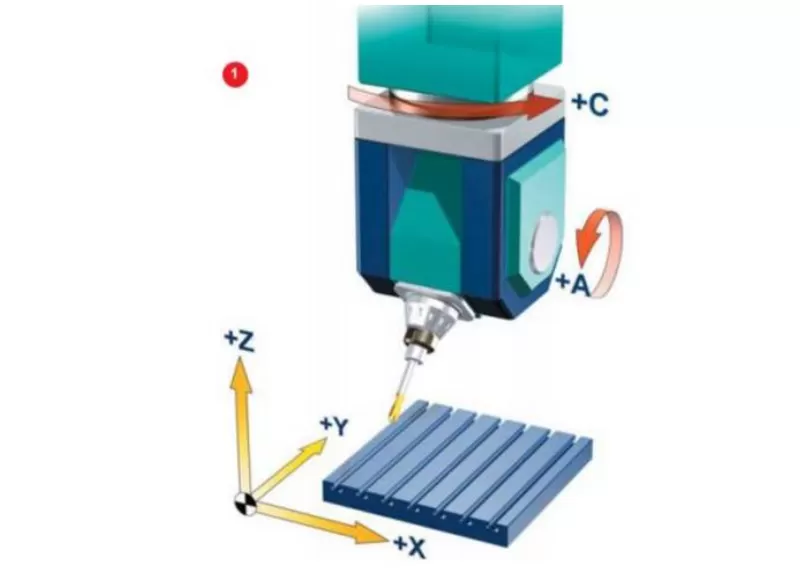

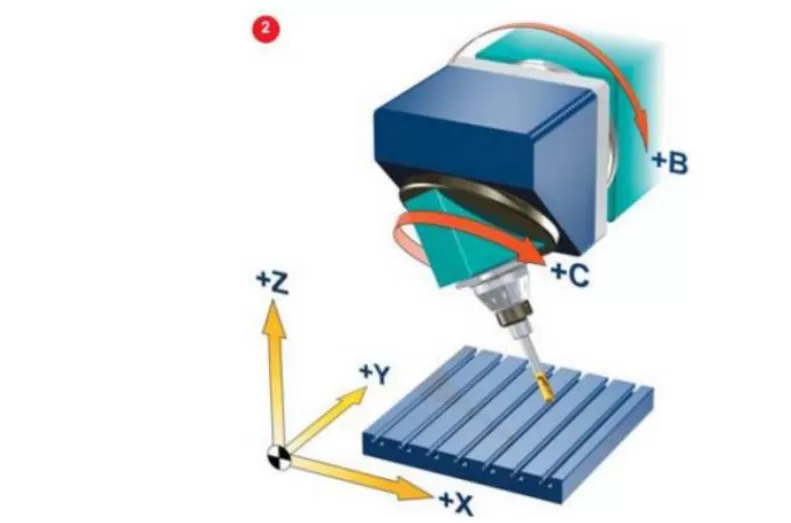

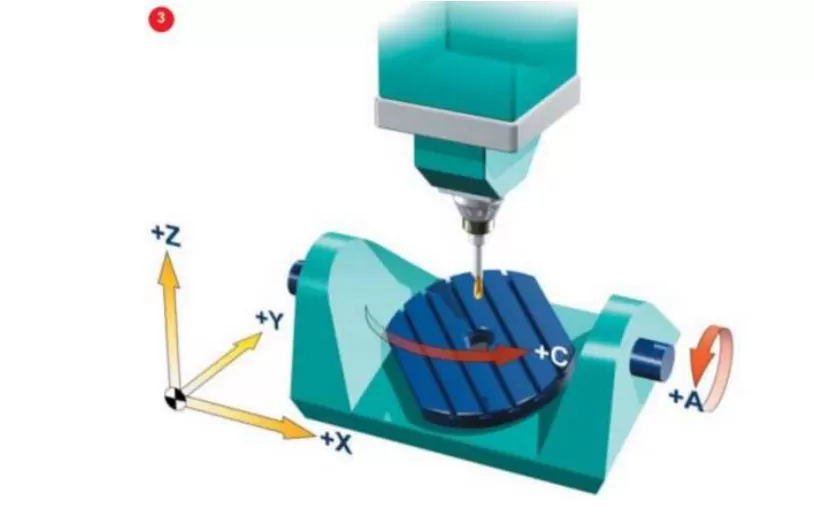

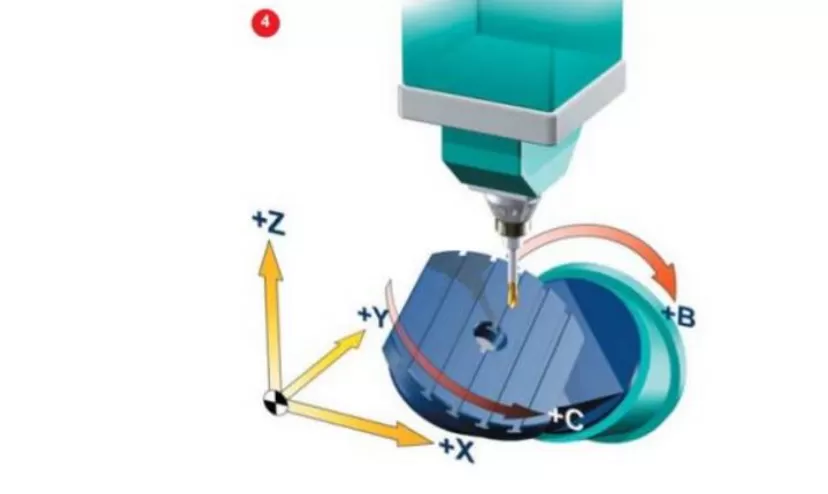

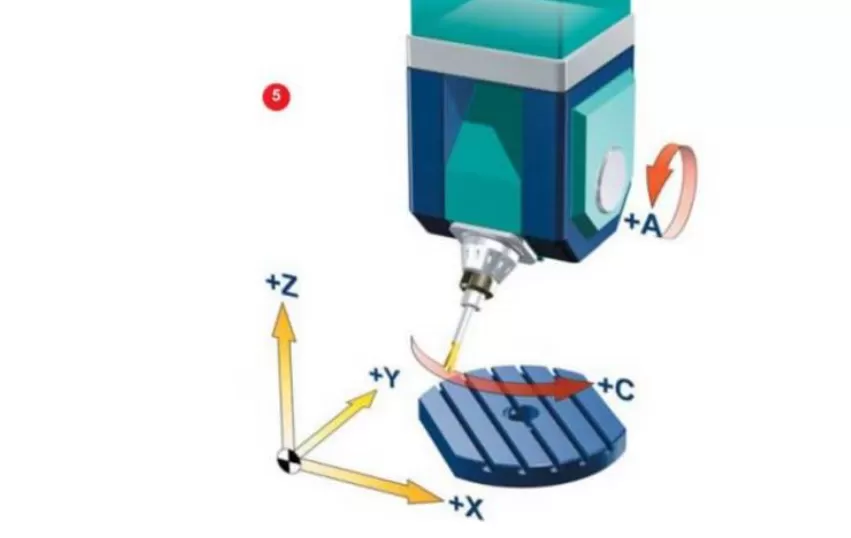

To truly understand 5-axis machining, first we need to understand what a 5-axis machine tool is. A 5-axis machine tool, as the name suggests, refers to adding two rotating axes to the three common linear axes X, Y, and Z. A. The two rotating axes in the B and C axes have different motion modes to meet the technical requirements of various products.

In the mechanical design of 5-axis machining centers, machine tool manufacturers have always been committed to developing new motion modes to meet various requirements. Considering the various types of 5-axis machine tools currently on the market, although their mechanical structures are diverse, there are mainly the following forms:

1.Two rotating coordinates directly control the direction of the tool axis (in the form of a double pendulum head).

2.Two coordinate axes are at the top of the tool, but the rotation axis is not perpendicular to the straight axis (vertical pendulum type).

3.Two rotational coordinates directly control the rotation of space (in the form of a double turntable).

4.Two coordinate axes are on the workbench, but the rotation axis is not perpendicular to the straight axis (vertical workbench).

5.Two rotating coordinates, one acting on the tool and one acting on the workpiece (in the form of one swing and one rotation).

*If the axis of rotation is not perpendicular to the straight axis, it is considered a “vertical” axis.

Numerous advantages of 5-axis CNC machining

Compare with traditional 3-axis equipment. Three axis processing equipment is common in production, including vertical, horizontal, and gantry forms. Common processing methods include end milling cutter edge machining and side edge machining. The profiling processing of ball end knives, and so on.

However, regardless of the form and method, there is a common characteristic that the direction of the tool axis remains unchanged during the machining process, and the machine tool can only achieve the motion of the tool in the spatial Cartesian coordinate system through the interpolation of the X, Y, and Z linear axes. So, when faced with the following products, the drawbacks of low efficiency, poor surface quality, and even inability to process of 3-axis machine tools are exposed.

Compared to 3-axis CNC machining equipment, 5-axis CNC machine tools have the following advantages:

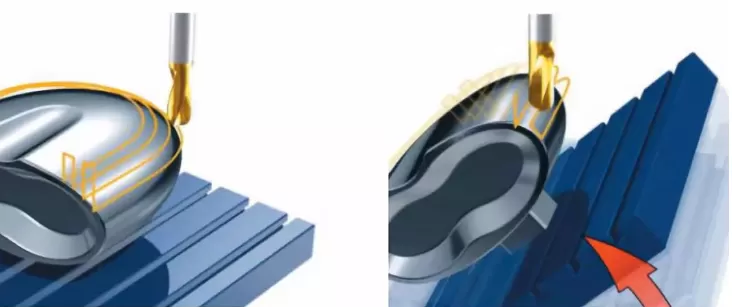

1.Maintain the optimal cutting state of the tool and improve cutting conditions

As shown in the above figure, in the left figure, the 3-axis cutting method gradually deteriorates the cutting state as the cutting tool moves towards the top or edge of the workpiece. To maintain the optimal cutting state here, it is necessary to rotate the workbench. If we want to fully process an irregular plane, we must rotate the workbench multiple times in different directions. It can be seen that the 5-axis machine tool can also avoid the situation where the center point line speed of the ball end milling cutter is 0, achieving better surface quality.

2.Effectively avoiding tool interference

As shown in the above figure, for components such as impellers, blades, and integral bladed discs used in the aerospace industry, the 3-axis equipment cannot meet the process requirements due to interference. And a 5-axis machine tool can meet this requirement. At the same time, the 5-axis machine tool can also use shorter tools for processing, improving system rigidity, reducing the number of tools, and avoiding the generation of specialized tools. For our business owner, it means that in terms of tool costs, 5-axis machine tools will save you money!

3.Reduce clamping times and complete 5 sided machining in one clamping process

As can be seen from the above figure, the 5-axis machining center can also reduce benchmark conversion and improve machining accuracy. In actual machining, only one clamping is required, making it easier to ensure machining accuracy. At the same time, due to the shortening of the process chain and the reduction of the number of equipment in the 5-axis machining center, the number of fixtures, workshop area, and equipment maintenance costs have also decreased. This means that you can complete more efficient and high-quality machining with fewer fixtures, less factory area, and maintenance costs!

4.Shorten the R&D cycle of new products

For enterprises in the fields of aerospace, automotive, and shipbuilding, some new product parts and forming molds have complex shapes and high precision requirements. Therefore, 5-axis CNC machining centers with high flexibility, precision, integration, and complete processing capabilities can effectively solve the accuracy and cycle problems of complex parts machining in the new product development process, greatly shortening the research and development cycle and improving the success rate of new products.

Science popularization: “RTCP” in 5-axis machining

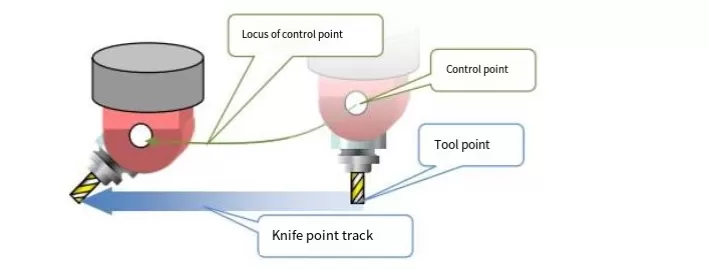

RTCP, in the high-end 5-axis numerical control system, that RTCP is the Rotated Tool Center Point, that is, we often say that the tool point follow function.

In 5-axis machining, when the trajectory of the tool point and the attitude between the tool and the workpiece are pursued, the additional motion of the tool point is generated due to the rotating motion. The control point of the CNC system often does not coincide with the tool point, so the CNC system should automatically correct the control point to ensure that the tool point moves according to the established trajectory of the instruction. This technology is also known in the industry as TCPM, TCPC or RPCP features. In fact, the functional definition of these names is similar to RTCP, strictly speaking, RTCP function is used in the double swing head structure, is the application of the swing head rotation center point to compensate. The function similar to RPCP is mainly applied to the machine tool in the form of double turntable, which compensates for the change of the linear axis coordinates caused by the rotation of the workpiece.

In fact, these functions are all in order to keep the center point of the tool and the actual contact point between the tool and the workpiece surface unchanged.

Common applications of 5-axis CNC machining

Due to its ability to cut at multiple angles and directions, 5-axis CNC machining is suitable for machining complex geometrics and high-precision workpieces. The following are some common application areas of 5-axis CNC machining:

Aerospace industry

In the aerospace field, complex engine parts, turbine blades, aircraft structural parts, etc., need high-precision machining, 5-axis CNC machining can achieve fine processing of these parts, improve the quality and performance of parts.

Automobile manufacturing

Automotive parts often need to have complex surfaces and geometric shapes, 5-axis CNC machining can be used to manufacture engine cylinder heads, body parts, seat structures and so on. This helps to improve the strength, lightweight and aerodynamic performance of automotive parts.

Medical device manufacturing

Medical devices usually require high precision and surface quality, and 5-axis CNC machining can be used to manufacture prosthetic limbs, implantable medical devices, dental equipment, and so on. This ensures the medical safety and comfort of the device.

Art and sculpture

5-axis CNC machining can be used for engraving and art production, which can produce artworks with complex textures, curves and shapes, such as sculptures and engraving works.

Mold making

Manufacturing complex molds and mold core parts require a high degree of precision and surface quality, 5-axis CNC machining can be used to manufacture injection molds, die casting molds, etc., to improve the accuracy and durability of the mold.

conclusion

5-axis CNC machining, as an advanced machining process, is gradually becoming one of the key technologies in the manufacturing industry due to its advantages in complex parts processing, precision control, design freedom, and production efficiency. With the continuous progress and innovation of technology, it is believed that 5-axis CNC machining will demonstrate its strong potential in more fields and bring more possibilities for the development of the manufacturing industry.

Longsheng is the world’s leading CNC machining service provider. With a wide range of 5-axis CNC machines, our robust 5-axis CNC machining services can manufacture high quality, fast lead times and competitive prices for high precision CNC machined parts.

Our highly skilled technicians also provide technical support to help you choose between our range of processing technologies and production-grade materials. Please contact us today so we can discuss your project.

Mobile:+86 18566759667(Gloria Wu)

E-Mail:gloria.wu@longshengmfg.com