CNC machines have revolutionized the manufacturing industry, allowing for precision machining of a wide variety of materials. In this article, we will discuss five different materials that can be used on CNC machines.

5 different materials that can be used on CNC machines

1. Metals

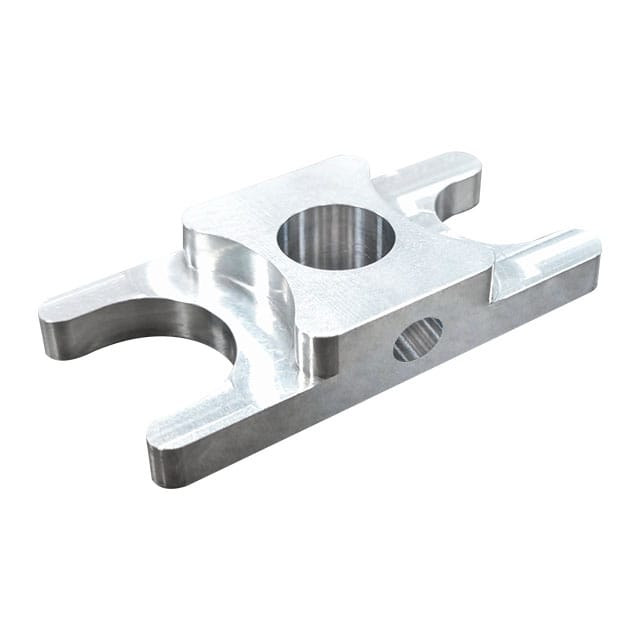

Metals are one of the most commonly used materials in CNC machining. They are strong, durable, and can be machined to very tight tolerances. Common metals used on CNC machines include aluminum, brass, copper, and steel.

2. Plastics

Plastics are another popular material used on CNC machines. They are lightweight, easy to machine, and come in a wide range of colors and finishes. Some common plastics used on CNC machines include acrylic, nylon, and PVC.

3. Wood

Wood is a natural material that can be machined on CNC machines to create intricate designs and shapes. It is commonly used in the furniture industry, as well as in the production of musical instruments and decorative items.

4. Composites

Composites are materials made up of two or more other materials. They are commonly used in aerospace and automotive industries due to their high strength-to-weight ratio. Common composites used on CNC machines include carbon fiber and fiberglass.

5. Ceramics

Ceramics are another material that can be machined on CNC machines. They are commonly used in the production of high-performance parts due to their high strength, hardness, and resistance to wear and corrosion.

CNC machining technology of different materials

CNC technology has revolutionized the manufacturing industry by providing accurate and efficient machining processes. Different materials require different CNC machining techniques to achieve the desired outcome.

Metals

Metals are widely used in various industries due to their unique properties such as durability and strength. CNC machining of metals involves the removal of material by cutting or drilling. The use of lubricants and coolants is essential to prevent overheating and prolong tool life. Common metals that are CNC machining include aluminum, steel, copper, and titanium.

Plastics

CNC machining of plastics involves a wide range of materials such as acrylic, PVC, nylon, and polycarbonate. The machining process involves using high-speed cutting tools to remove material. The process requires a high degree of precision to avoid melting, deformation, or burring of the material. The use of coolants is necessary to avoid overheating of the plastic.

Wood

CNC machining of wood involves the use of specialized cutting tools to carve or engrave wood. The process requires a high level of accuracy to produce intricate designs. The use of coolants is not necessary as wood does not overheat during the machining process. Common wood types that are CNC processed include MDF, plywood, and hardwood.

Composites

Composites are materials made from two or more materials, such as fiberglass and carbon fiber. CNC machining of composites involves the use of specialized cutting tools to remove material. The process requires a high degree of precision to avoid damaging the fibers. The use of coolants is necessary to prevent overheating and delamination of the composite.

CNC machining technology has made it possible to process different materials with a high degree of accuracy and efficiency. The type of material being processed determines the CNC machining technique to be used. Proper selection of cutting tools, lubricants, and coolants is essential to achieving the desired outcome.

In conclusion, CNC machines can be used to machine a wide variety of materials, including metals, plastics, wood, composites, and ceramics. Each material has its own unique properties and advantages, making them suitable for different applications.