In recent years, with the progress of the fourth industrial revolution, the manufacturing industry has also ushered in a period of prosperous development. The rapid development of CNC machining and milling has also injected new sources into all walks of life. Let’s take a look at CNC machining services and their related advantages.

What is CNC Machining?

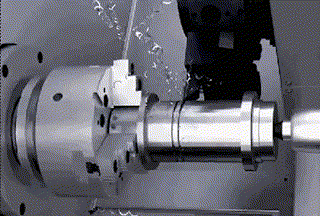

Computer numerical control, referred to as Numerical Control. It is a method that uses digital information to control machine tool movement and processing processes. Among them, CNC machine tools are products that are highly integrated with machinery, electricity, fluids, gas and light, such as CNC lathes, CNC milling machines, CNC boring and milling machines, etc. Compared with traditional mechanical processing, CNC machining has many advantages such as high precision and efficiency, and has become the first choice for manufacturing and processing in all walks of life.

Making surface grooves on a lathe

CNC machining applications

CNC machining has a wide range of applications and is used in many industries in daily life and manufacturing, such as:

| Mechanical parts manufacturing | CNC machining is widely used in the manufacturing of various mechanical parts, such as gears, shafts, bearing seats, etc. These parts often have complex shape and accuracy requirements that CNC machining can easily meet. |

| Aviation and aerospace components | Since aviation and aerospace components have very high requirements for precision and strength, CNC machining is widely used in these fields. For example, aircraft engine blades, rocket engine nozzles, etc. can be produced through CNC processing. |

| Medical device manufacturing | The production of medical devices has high requirements for precision and cleanliness. Using CNC processing can ensure product quality while improving production efficiency. For example, medical implants, prostheses, etc. can be produced through CNC processing. |

| Electronic equipment manufacturing | Electronic equipment has high requirements for the accuracy and stability of components. By using CNC machining, the performance and quality of electronic products can be improved. For example, circuit boards, mobile phone casings, etc. can be produced through CNC processing. |

| Mold manufacturing | Molds are an important part of many industrial products, such as injection molds, die-casting molds, etc. Using CNC processing can improve the manufacturing efficiency and quality of molds, thereby reducing production costs. |

Using this method, manufacturers can create a variety of simple or complex parts that meet customer needs.

What are the Benefits of CNC Machining?

Due to various reasons such as technological development or advancement of the times, CNC machining has become very popular in various industries. Here are 8 main advantages of CNC machine tools.

CNC manual profiling turning

High precision and accuracy

CNC numerical control machining uses advanced computer programming and control technology to accurately control the movement trajectory and processing parameters of the tool, thereby achieving micron-level or higher-level processing. The typical accuracy of today’s CNC machine tools has reached two thousandths to four thousandths of an inch or 0.05 to 0.10 millimeters, and the repeatability accuracy is close to or better than eight thousandths of an inch or 0.02 millimeters. This means that once a program is verified, two, ten or a thousand identical parts can be easily produced with the same accuracy and consistency, achieving mass production and meeting the industry’s stringent requirements for precision parts.

High efficiency

Compared with traditional manual processing methods, CNC processing can realize automated continuous processing, which not only greatly reduces manual operation errors, but also can quickly complete the processing of complex parts, greatly improving production efficiency. At the same time, because the CNC machining center can complete multiple processing tasks at the same time, it can also reduce the clamping and replacement time of workpieces, further improving production efficiency. In addition, CNC machining can also achieve multi-axis linkage and efficiently process complex curved surfaces and shapes, thus improving production efficiency and processing quality, helping companies quickly respond to market demand to enhance competitiveness.

High adaptability

CNC processing can be adapted to various materials, whether they are high hardness materials or brittle materials, including metal, plastic, wood, etc., it can be easily processed. Not only that, CNC can also adapt to the processing of various complex parts. Whether it is a simple straight line, an arc, or a complex curved surface or spatial structure, it can be processed accurately through programming, making product design more free and flexible.

Programmability

CNC machining can control the machine tool through computer programming, so that different machining operations can be achieved. This makes CNC machining very flexible and adaptable to different market needs and different workpiece types. At the same time, since CNC machining is digitally controlled machining, computer simulation technology can be used to simulate the machining process and verify the correctness of the program, thus ensuring machining quality and accuracy.

Strict quality control

The precise control and repeatability of CNC machining make product quality more stable and reliable. And because each part is processed according to the same standards, the quality differences caused by human factors are greatly reduced, which not only improves the product qualification rate and consistency, but also reduces the scrap rate and rework rate.

Promoting the development of intelligence

Through the integration with other advanced technologies such as the Internet of Things and artificial intelligence, CNC processing realizes real-time monitoring, data analysis and optimization adjustment of the processing process, further improving the efficiency and quality of operations and moving the manufacturing industry to a higher level.

environmental protection

The mechanization of CNC processing reduces the waste rate of materials, not only improves material utilization, but also reduces energy consumption, which meets the requirements of sustainable development in today’s society.

Cost savings

Although the initial equipment investment for CNC machining is relatively high, with the popularization and use of CNC machining equipment, the supply will increase and the cost will decrease. Moreover, its efficient processing ability and stable product quality can greatly reduce the costs in the production process, reduce labor costs, material losses, and subsequent processing costs, and improve the economic benefits of enterprises.

What are the drawbacks of CNC machining?

Although CNC machining has many advantages, there are also two drawbacks that need to be noted:

- Need to purchase a large amount of milling machine processing equipment

- High tech maintenance personnel and operators are required

Why choose Longsheng for your CNC machining service?

If you want to customize high-quality CNC machining services, you may wish to consider Dongguan Longsheng Hardware Technology Co., Ltd. We are a professional manufacturer with many years of mature experience in providing CNC machining services. We can produce diameters ranging from 0.030 inches to 2 inches. Works to meet the unique specifications of the most demanding applications. In addition, we are able to deliver quickly in just 10 days, provide one-stop service, and support online customized processing. For more information, simply contact us today or request a quote, a professional technician is waiting for you!

Conclusion

Through the above description, I believe everyone has a certain understanding of the advantages of CNC processing. In short, CNC machining has the advantages of high efficiency, high precision, and high adaptability, making it widely used in modern manufacturing. With the continuous advancement of technology and changing market demands, CNC processing will play a more important role in the future manufacturing industry. If you have any questions, please comment below!

frequently asked questions

What is the role of CNC machining?

CNC machining is a manufacturing process that uses computer numerical control systems to control the movement and operation of machine tools. It is capable of performing various tasks such as precise cutting, shaping, drilling, milling, and turning of a wide range of materials. It can produce complex and highly accurate parts and components with tight tolerances. CNC machining is widely used in industries like aerospace, automotive, electronics, medical, and many others to create high-quality products with consistent quality and performance. It allows for efficient mass production as well as the customization of individual parts, meeting the diverse needs of different applications.

What is CNC vertical milling?

CNC vertical milling is a machining process in which a rotating cutting tool is used to remove material from a workpiece. In a CNC vertical milling machine, the workpiece is held firmly in place on the worktable, while the cutting tool spins and moves vertically along the z-axis and horizontally along the x and y axes, controlled by a computer numerical control system. This enables precise and accurate shaping, drilling, slotting, and other operations to be performed on the workpiece. It is widely used for manufacturing various components, prototypes, and complex geometries in industries such as aerospace, automotive, and mechanical engineering. The ability to program complex tool paths and achieve high precision makes CNC vertical milling a crucial process for producing high-quality and intricate parts.

Briefly introduce the basic process of CNC machining.

The basic process of CNC machining typically involves several steps. First, the design of the part to be machined is created using CAD software. Then, the CAD file is converted into a CNC program that instructs the machine on the specific tool paths and operations. The workpiece is then securely fastened on the machine’s worktable. The CNC machine, guided by the program, starts the machining process, with the cutting tool precisely removing material according to the pre-defined paths. This may include milling, drilling, turning, or other operations. Throughout the process, coolant is often used to cool the tool and workpiece and remove chips. Finally, the machined part is inspected for quality and accuracy to ensure it meets the required specifications.

Resource

Development Trend of NC Machining Accuracy Control Technology for Aeronautical Structural Parts

Pingback: Custom CNC Parts Manufacturing | Precision CNC Machining Services Near You

Thank you for your support and attention, we provide you with valuable content every day.

Thank you for your support and attention, we provide you with valuable content every day.