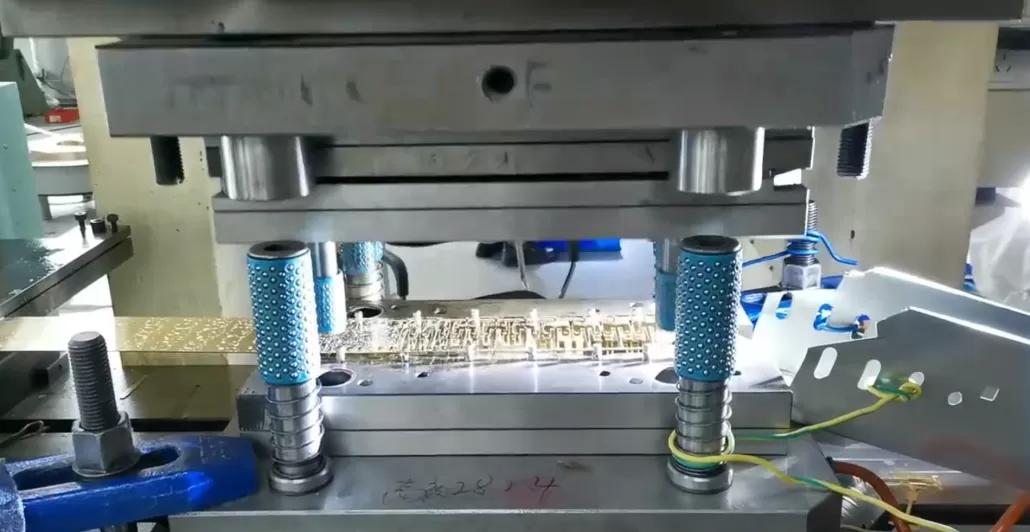

Metal stamping forming is an industrial process which is widely used in fabrication, manufacturing, and construction industries. It involves the use of specialized machinery to transform sheets of metal into desired shapes and sizes.

If you are considering metal stamping forming for your company, it is important to understand the various manufacturing processes involved. In this article, we’ll be discussing the eight most commonly used manufacturing processes for metal stamping forming. From simple cutting and punching to more complex operations like coining and bending, each of these processes plays a critical role in the successful production of high-quality metal products.

1.Blanking

Blanking is the process of cutting a flat piece of sheet metal into a specific shape. This process is achieved by using a blanking die and a punch. The sheet metal is placed between the die and punch, and pressure is applied to create the desired shape.

2.Piercing

Piercing is the process of creating holes in the sheet metal. This process is achieved by using a piercing die and a punch. The sheet metal is placed below the punch and the piercing die is lowered onto it.

3.Bending

Bending is the process of creating a V-shaped or U-shaped channel in the sheet metal. This is achieved by using a v-bending die and a punch. The sheet metal is placed in the die and clamped in place while the punch is lowered onto it to create the desired shape.

4.Drawing

Drawing is the process of creating a part by forming a flat sheet of metal into a three-dimensional shape. This process is achieved by using a drawing die and a punch. The sheet metal is placed in the die and clamped in place while the punch is lowered onto it to create the desired shape.

5.Embossing

Embossing is the process of creating a three-dimensional design on the surface of the sheet metal. This process is achieved by using an embossing die and a punch. The sheet metal is placed in the die and clamped in place while the punch is lowered onto it to create the desired design.

6.Coining

Coining is the process of shaping the edges of the sheet metal. This process is achieved by using a coining die and a punch. The sheet metal is placed in the die and clamped in place while the punch is lowered onto it to create the desired edge shape.

7.Stamping

Stamping is the process of creating a part by stamping the sheet metal with a die. This process is achieved by using a stamping die and a punch. The sheet metal is placed in the die and clamped in place while the punch is lowered onto it to create the desired shape.

8.Forming

Forming is the process of shaping the sheet metal into a curved or angled shape. This process is achieved by using a forming die and a punch. The sheet metal is placed in the die and clamped in place while the punch is lowered onto it to create the desired shape.

In conclusion, metal stamping forming is an important manufacturing process that is used to create a wide range of parts. There are several different manufacturing processes that can be used to achieve the desired result. Choosing the right process for your needs will help you achieve precision parts that meet your exact specifications.