What is sheet metal fabricators?

Sheet metal fabrication is an umbrella term for a group of processes that use sheet metal to build machines and structures. It can be a complex process involving many different professionals. Businesses that specialize in sheet metal fabrication are commonly referred to as fabrication shops, or fab shops for short. So whether you are looking for sheet metal fabrication in China, we can accommodate your needs and assist with guidance on manufacturing and best practices.

Metal has been hand-hammered into sheets and used for architectural purposes since ancient times. Water-powered rolling mills replaced hammering in the late 17th century. This method of flattening metal used large rotating iron cylinders to press metal pieces into sheets. The metals used were lead, copper, iron, zinc, and later steel. Tin was frequently used to coat iron and steel sheets to prevent rusting. This tin-coated sheet metal was called “tinplate.”

Sheet metal became popular in the United States in the 1870s, used for shingle roofing, stamped ornamental ceilings, and exterior façades. With further advances in sheet metal production in the 1890s, the promise of being cheap, durable, easy to install, and fireproof gave the middle class a significant appetite for sheet metal products.

What does Sheet Metal Fabrication mean?

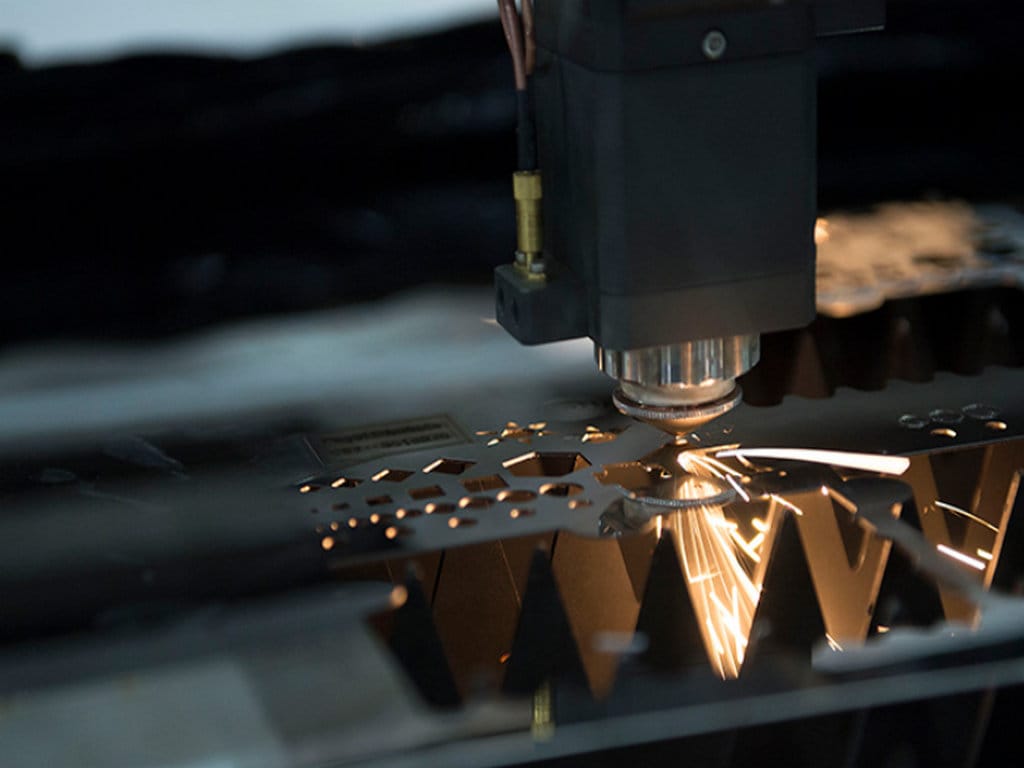

Well simply put – Sheet Metal Fabrication is the process of manufacturing sheet metal to make them conform to specific shapes. This takes place through a series of manufacturing processes like cutting, bending, shaping, punching, and welding. Another related practice is a custom fabrication – which LS technology is all about – meaning the creation of new custom parts using novel combinations of these processes mentioned.

Why Sheet Metal Fabricators are so important?

Once you realize how many things around you are made of metal, you can’t help but see it.

Our economy relies on metal fabrication processes. Without it, we wouldn’t be able to run our electrical systems or create the parts that keep our houses, kitchens, businesses, computers and vehicles operational. All this work is completed by metal fabricators — highly skilled specialists who are trained to cut and manipulate metal to the desired shapes.

Types of Sheet Metal Fabrication Metals

Sheet metal can come in a wide variety of types, and fabrication can adapt the metal to whatever purposes you may need. Types of common metals used in sheet metal fabrication include:

- Steel – all four classifications of steel are prominent for robust strength, ductility, and resistance to corrosion

- Aluminum – a relatively lightweight metal with high strength

- Magnesium – a shiny, lightweight, and strong metal with low density making it adequate for structures that require stiffness

- Bronze – a very high ductile metal with a low melting point

- Copper – a soft and malleable metal with heat and electrical conductivity

Types of Metal Fabrication Processes

The journey from sheet metal to metal products starts with CAD engineering. After making the models, each part goes through the necessary sheet metal fabrication processes. The most common ones are:

- Cutting – Shear, CNC Punch presses, Lasers, Waterjet, plasma

- Bending – Press brakes, folding machines, panel benders

- Welding – Mig, Tig, robotic, laser

- Hardware insertion – Haeger Presses

- Grinding & Graining – cleaning up welds, belt sanding to put nice grained finish.

Custom sheet metal fabrication at LS technology

Metal fabrication starts with an idea, typically born out of necessity, that involves a piece of metal suited for some particular task. Here at LS technology we have senior and experienced 3D-CAD developers that can take your existing or new ideas to the next level.

While some companies may have the capability to handle standard metal fabrication in-house, most companies don’t have the in-house machinery and expertise to accomplish custom designs. Here at LS technology we can custom design, manufacture and assemble your products in our factory – NO OUTSOURCING involved.

Top-quality fabrications are only possible when you begin with top-quality parts. LS technology has modern CNC machinery, skilled employees and unwavering commitment necessary to manufacture perfect parts every time. We understand the importance of custom metal fabricated for your metal product in our shop.

Conclusion

You can rely on LS technology for:

- An exceptional customer experience

- Custom/Standard Products

- We are a Siemens Approved Manufacturer

- We are ISO 9001:2015 Certified

- Our Panels are type tested

- A Trusted Partnership – with no proprietary products of our own, we are totally dedicated to helping you succeed

- Top quality products

- Highly skilled professionals & craftsmen

- Fast delivery

LS technology located in Dongguan China is a leader in metal fabrication services. Our innovative team is particularly adept at taking existing technologies and modifying or customizing them to meet unique customer needs. With over 10 years of laser and program management expertise, our full-service offerings include state of the art laser, forming, machining, welding and more.

If you have questions regarding metal fabrication and laser cutting services, call us.