What is CNC Machining?

CNC machining, also known as computer numerical control machining, is a manufacturing process that utilizes computers to control machine tools. It was originally developed in the early 1950s to make complex shapes and components from materials like metal and plastic. With CNC machining, the user is able to create a variety of components with different shapes, sizes, and tolerances. Since the introduction of CNC technology, it has become one of the most popular processes used in manufacturing today.

How Does CNC Machining Work?

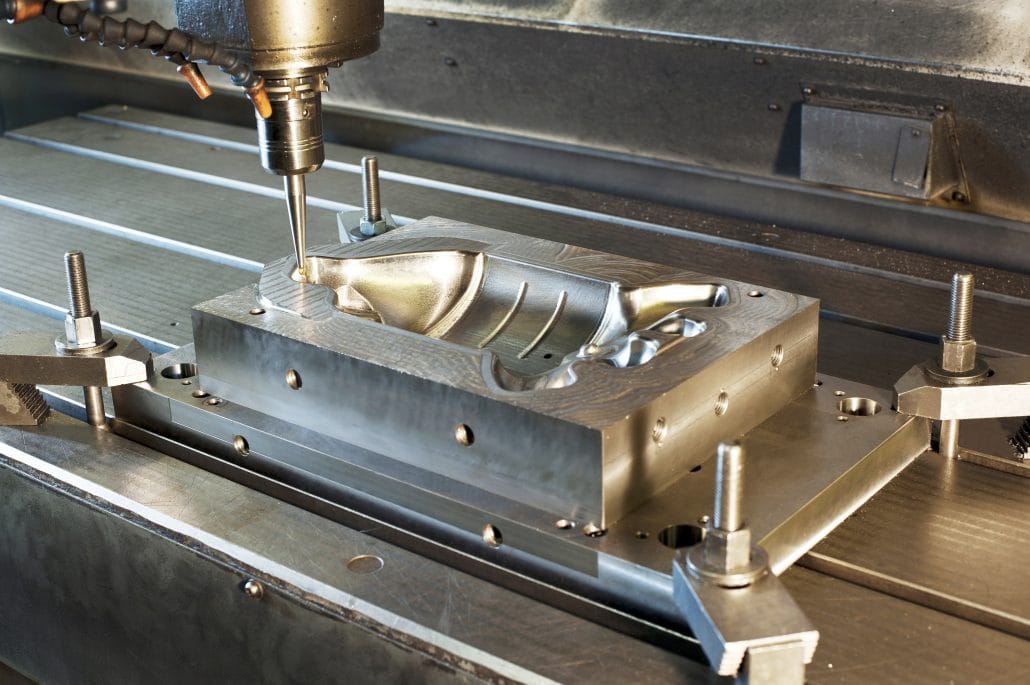

In CNC machining, the user creates a design using Computer Aided Design (CAD) or Computer Aided Manufacturing (CAM) software. The design is then sent to a CNC machine, where the tools are set up and the machine is programmed. After programming has been completed, the machine begins cutting the material according to the specifications of the design.

The CNC machine is typically composed of several different components that work together to create the desired shape and size of the product being machined. These components include the spindle, the tooling system, the drive system, and the work table.

The spindle is the main cutting tool of the machine and is responsible for holding and rotating the cutting tool at high speeds. The cutting tool itself is typically attached to the spindle via an indexable tool holder, which allows for quick and easy changes of tools. The drive system is made up of servo motors, commonly referred to as stepper motors, which control the movements of the cutting tool and work table.

The work table is the platform on which the material being machined is placed. Depending on the type of machine, there are typically several options for securing the material in place. These options include clamps, vacuum tables, or fixtures.

The tooling system is responsible for guiding the cutting tool along the designated path. This is done by the use of linear guides, ball screws, and linear motors. In addition to these components, there are also sensors and controllers, which are responsible for monitoring the progress of the machining operation.

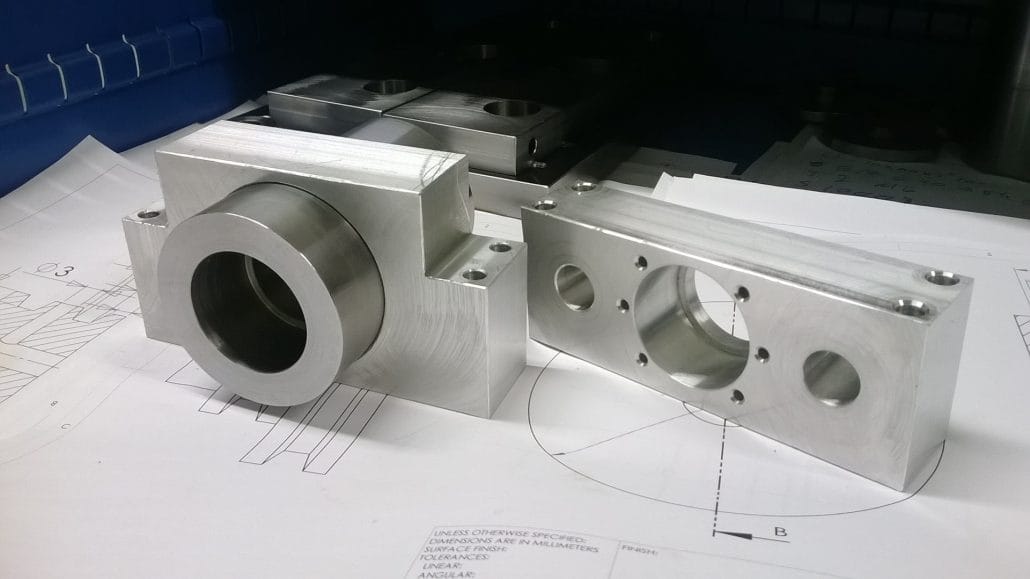

Once the machining operation is finished, the part is inspected for accuracy and quality. This is typically done with a coordinate measuring machine (CMM). The CMM can measure the dimensions of the part against the designed parameters and indicate any discrepancies.

Advantages of CNC Machining

CNC machining offers numerous benefits to the user. First and foremost, the process is highly accurate and repeatable. The cutting tools used in the process are highly precise and can produce components with very tight tolerances. This accuracy is also due in part to the programming of the CNC machine itself, as it ensures that the cutting tool follows the exact path specified by the programmer.

CNC machining is also cost effective, as it allows for the production of many parts in a short amount of time. This is especially true when compared to the traditional manual machining process, which is often slower and more costly.

Another important benefit of CNC machining is its flexibility. Unlike manual machining, which typically involves the use of a single cutting tool, CNC machining can accommodate multiple cutting tools and materials. This allows for more freedom in the design of components, as different materials and cutting tools can be used depending on the desired outcome.

Finally, CNC machining is safe and reliable. Since all of the machining operations are conducted under computer control, human error is eliminated and the risks associated with the process are greatly reduced.

Conclusion

CNC machining is a versatile and efficient manufacturing process that has revolutionized the way manufacturers produce components. The process offers numerous benefits, including cost savings, accuracy, repeatability, flexibility, and safety. As the technology continues to evolve, it is likely that CNC machining will become increasingly popular among manufacturers.

Related product processing customized services:

CNC Machine Parts Manufacturer

CNC Milling Parts Machining Service

High -Precision CNC Turning Machine Parts

Sheet Metal Machining Parts Center