CNC (Computer Numerical Control) machining is an essential process in the manufacturing of medical parts. This technology has significantly improved the accuracy, efficiency and cost-effectiveness of part production over manual operations. CNC machines are used to create intricate parts and components for medical equipment, drug delivery systems, implants and prosthetics, as well as specialized orthopedic instruments.

The Benefits of CNC Machining for Medical Applications

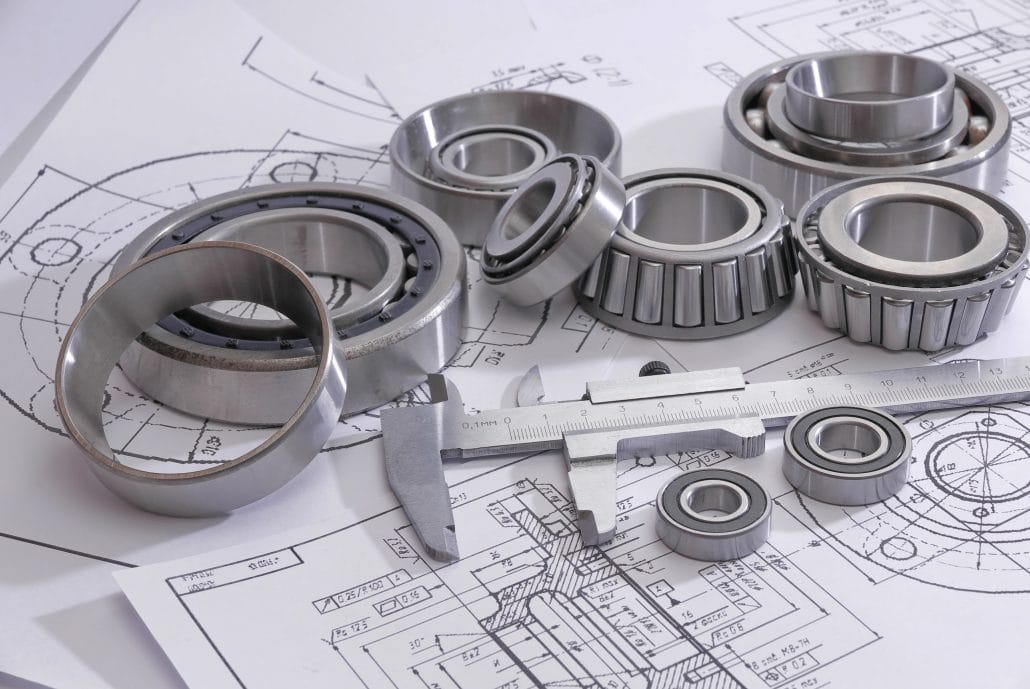

CNC machine parts manufacturers provide an array of services that can benefit medical device production. Using high-precision CNC machining services, manufacturers can produce parts to exacting specifications with minimal tolerance variations. The machined parts have excellent surface finish and are resistant to corrosion and wear.

CNC machining also allows for greater flexibility in designing parts and components for medical applications. With the use of advanced CAD/CAM (Computer Aided Design/Computer Aided Manufacturing) software, engineers can quickly and easily modify existing designs and create new ones. CNC machining also enables complex shapes and intricate details to be produced with ease.

In addition, CNC machining can be used to produce a wide variety of metal and plastic parts. For example, sheet metal machining parts centers can create intricate pieces such as brackets and housings for medical equipment and devices. CNC machining can also be used to produce custom parts from a variety of materials including aluminum, brass, titanium and stainless steel.

Since CNC machining allows for the precise control of many parameters related to the machining process, manufacturers can be assured of producing parts with consistent quality and a high degree of repeatability. This makes it easier to mass-produce parts with the same design and dimensions, which can reduce overall production costs.

Types of CNC Machining for Medical Applications

There are a variety of CNC machining services available for medical applications. These include:

CNC Milling Parts Machining Services: CNC milling is used to produce parts with flat or curved surfaces, angles, grooves, slots and holes. CNC milling machines are equipped with high-speed spindles that spin at high speeds to create parts with intricate shapes.

Sheet Metal Machining Parts Center: Sheet metal parts such as brackets and enclosures can be manufactured using CNC machines. Sheet metal machining centers offer the advantages of accuracy and speed, as well as the ability to produce complex shapes.

CNC Turned Parts Machining Services: CNC turning is used to produce cylindrical and conical parts with a high degree of accuracy. CNC lathes are used to produce parts with features such as threads, grooves, gear teeth and keyways.

CNC Grinding Parts Machining Services: CNC grinding is used to produce parts with a high degree of surface finish and accuracy. CNC grinding machines are used to produce parts with features such as pins, cones, and deep chamfers.

CNC Wire EDM Parts Machining Services: CNC wire EDM is used to cut complex shapes and tight tolerances with superb surface finish. This process is often used to machine intricate shapes that cannot be produced with conventional methods.

Conclusion

CNC machining is an essential process for medical device production. It offers a range of benefits including accuracy, speed, flexibility, and cost-effectiveness. CNC machining services such as CNC milling, turning, grinding and wire EDM can be used to produce parts with intricate shapes and high degrees of surface finish and accuracy. In addition, CNC machining parts services can be used to produce custom parts from a variety of materials, including metals and plastics.