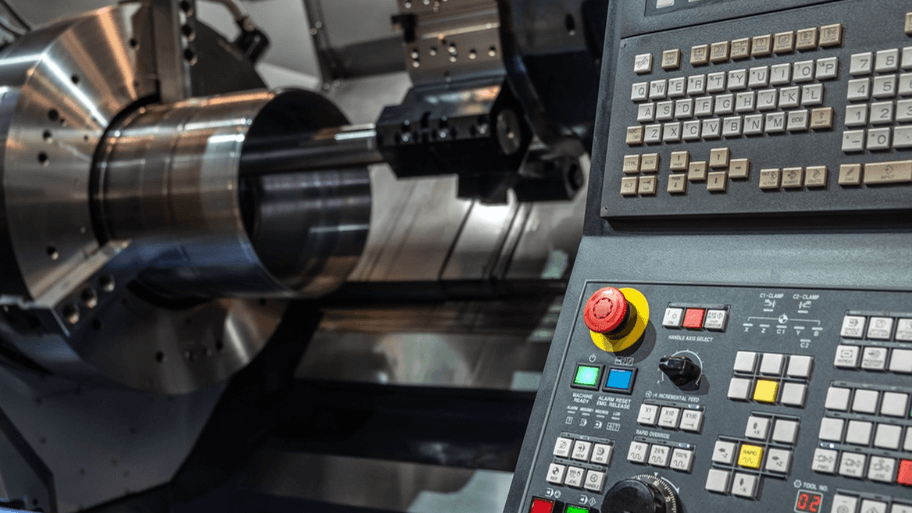

CNC milling machining plays a crucial role in manufacturing a variety of products and parts. In order to ensure optimal performance and desired outcomes, it is important to have the right tools and software to support the process. One of the most important tools in CNC milling machining is simulation software. In this article, we will discuss the importance of simulation software and its various benefits.

What is CNC Milling Machining Simulation Software?

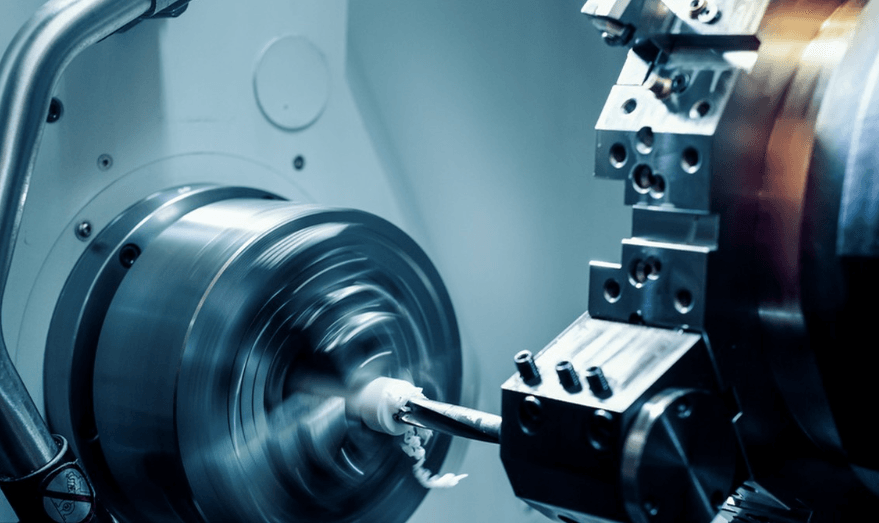

Simulation software is a computer program that allows users to model and simulate real-world scenarios. In the context of CNC milling machining, simulation software can be used to simulate the entire machining process, from toolpath creation to material removal. This software helps users to visualize the machining process and make necessary adjustments to optimize the process.

Benefits of Simulation Software for CNC Milling Machining

1. Reduced Cycle Times

One of the primary benefits of simulation software is that it allows users to optimize toolpaths and machining parameters, resulting in reduced cycle times. By simulating the machining process beforehand, users can identify potential issues and make necessary adjustments to optimize the process. This leads to a more efficient and streamlined process, reducing the time and cost involved in manufacturing products.

2. Improved Tool Life

Using simulation software, users can evaluate the impact of tool wear on the machining process. This allows for the optimization of cutting parameters, resulting in improved tool life and reduced tooling costs. By optimizing the cutting parameters, users can extend the life of their tools and reduce the need for frequent tool changes, which can be costly and time-consuming.

3. Reduced Scrap Rates

Simulation software allows users to identify potential issues such as collisions, gouges, and undercuts before the machining process begins. By addressing these issues beforehand, users can reduce scrap rates and minimize rework. This leads to a more efficient and cost-effective manufacturing process, as it reduces the need for additional materials and time spent on rework.

4. Enhanced Quality Control

Simulation software can be used to simulate the entire machining process, including inspection and measurement. By simulating the inspection process, users can identify potential quality issues and make necessary adjustments to ensure optimal quality. This leads to a higher level of quality control, reducing the risk of defects and ensuring consistent product quality.

Conclusion

Simulation software plays a critical role in CNC milling machining. By allowing users to simulate the machining process beforehand, simulation software can help optimize toolpaths, reduce cycle times, improve tool life, reduce scrap rates, and enhance quality control. Investing in simulation software can lead to significant cost savings and improved overall performance. With the right tools and software, manufacturers can achieve optimal results and maintain a competitive edge in the industry.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Milling Parts Machining Service,Custom Sheet Metal Paers Fabrication Service,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items