CNC milling machines are a staple in modern manufacturing, providing precision and efficiency in cutting and shaping materials. However, to fully maximize the benefits of these machines, customization is essential.

Customization allows for the creation of parts that are tailored to specific needs and requirements, which is critical in industries such as aerospace, automotive, and medical. These industries demand high-quality, precise parts that meet strict standards and regulations, and customization is the key to achieving this.

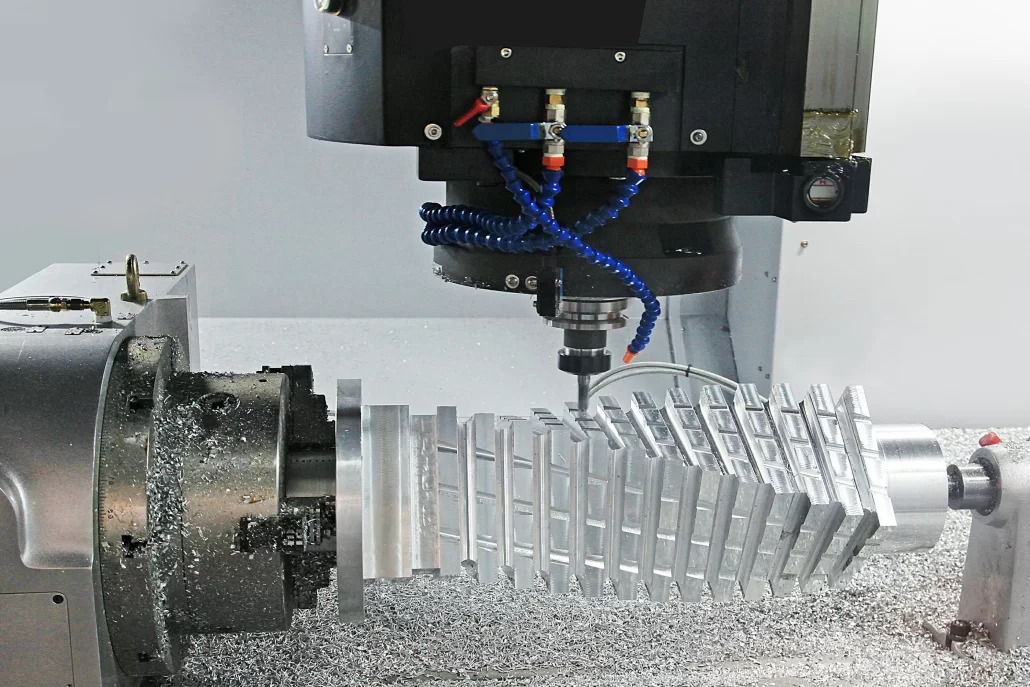

One benefit of customization is the ability to create complex geometries and intricate shapes that would be impossible to produce with traditional manufacturing methods. CNC milling machines can create parts with high accuracy and repeatability, ensuring that each part is identical to the next. This is essential in industries such as aerospace, where cnc parts must fit together perfectly and withstand extreme conditions.

Another benefit of customization is the ability to optimize the manufacturing process. By tailoring parts to specific needs, manufacturers can reduce waste, minimize production time, and increase efficiency. This not only saves time and money but also reduces the environmental impact of manufacturing.

In conclusion, customization is essential in CNC milling machine parts manufacturing. It allows for the creation of precise, high-quality parts that meet strict standards and requirements. Customization also enables manufacturers to optimize the manufacturing process and use a wide range of materials. As industries continue to demand increasingly complex and precise parts, customization will become even more critical in achieving success.