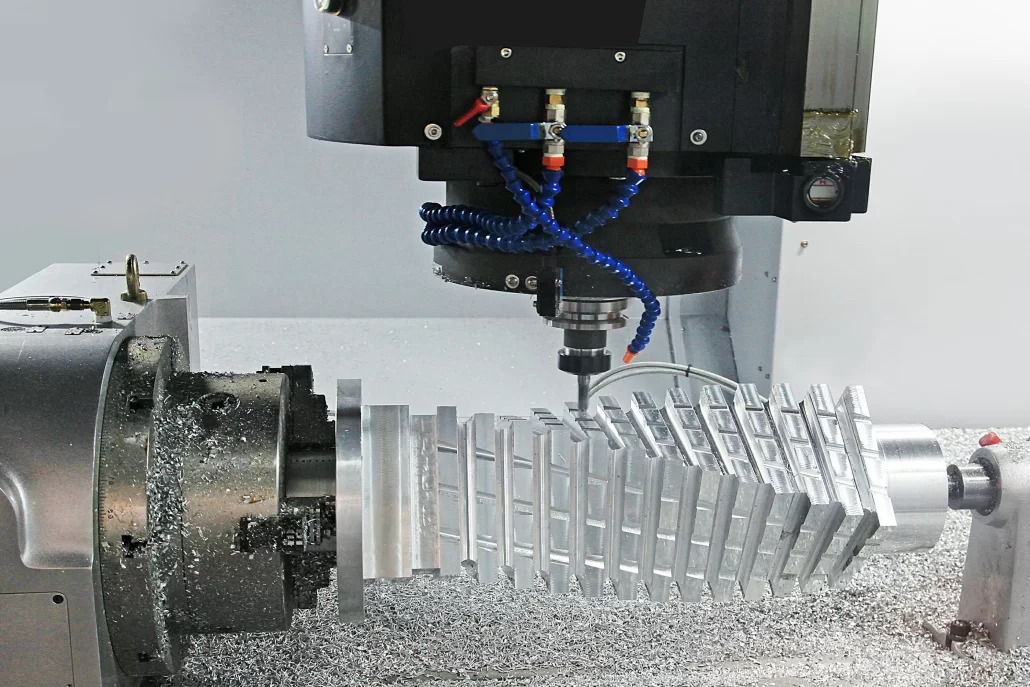

In the process of CNC machining, monitoring and adjustment is very important to ensure the quality of finished products to achieve the desired effect,how to monitor and adjust in cnc machining process?CNC machining process is a combination of machine movements and operations that require precise monitoring and adjustments to produce accurate parts with high precision. CNC machining involves a series of operations such as cutting, drilling, milling and turning that require detailed steps and parameters to be monitored and adjusted to maintain accuracy and reliability. With the advancement in CNC technology, there are now more efficient ways to monitor and adjust CNC machining processes.

Therefore, monitoring and adjustment are very important in CNC machining process, because they can help you get higher quality products, avoid errors and reduce waste. In this article, we’ll discuss some ways to monitor and adjust to ensure that your CNC machining process is as efficient as possible.

CNC Machining Monitoring

The most efficient way to monitor the CNC machining process is by using a CNC machine monitor. A CNC machine monitor is a device used to check the operation of a CNC machine by monitoring the movement of the machine and measuring the accuracy of the cuts and other machining operations. It also checks for any inconsistencies or errors in the machining process. This information is then transmitted to a computer system where it can be analyzed and used to make adjustments to the process.

Another way to monitor the CNC machining process is to use a laser system. Laser systems can be used to measure the accuracy of the machining operations by measuring the position of the tool with respect to the specific material being worked on. This data can then be automatically transmitted back to the computer system where it can be used to make adjustments.

CNC Machining Adjusting

Once the online CNC machining process has been monitored and the adjustments to be made have been determined, the next step is to adjust the CNC machine. This is done by entering the necessary data into the CNC controller. The controller is then able to make the necessary changes to the machining process in order to achieve the desired results.

The most important thing to remember when adjusting CNC machines is to ensure that the adjustments are precise and accurate. If the adjustments are not precise, it can result in inaccurate or rough parts being produced which can be costly and time consuming.

Conclusion

In conclusion, CNC machining process requires precise monitoring and adjusting to produce accurate parts with high precision. The most common methods of monitoring and adjusting CNC machines are using a CNC machine monitor and laser system. Once the adjustments have been made, they must be precise and accurate in order to achieve the desired results. By utilizing these methods, it is possible to ensure that CNC machining processes are running efficiently and accurately.

We hope this article will help you understand the monitoring and adjustment of CNC machining process.

longsheng