At last year’s Canton Fair, many people asked me, ‘What process are your precision parts made of?’? My answer is to use CNC machining, but many people have raised questions. Why don’t you use 3D printing to do it, but instead use CNC machining? It seems that 3D printing has gained market recognition, but as customers, they are not aware of a very real problem.

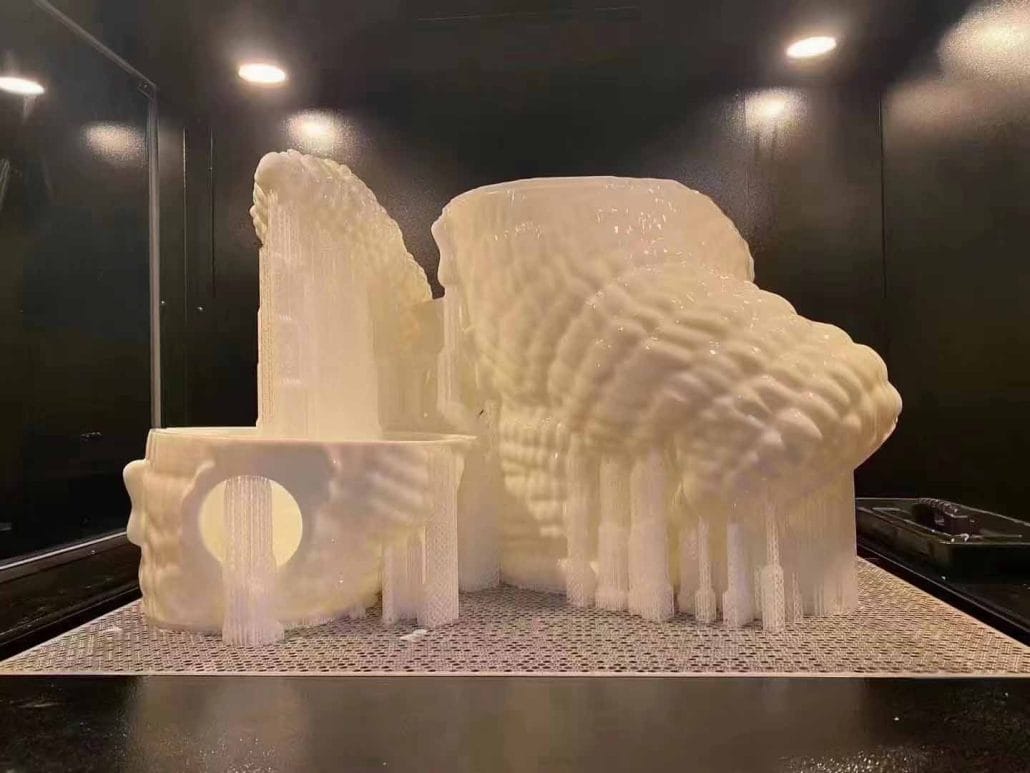

3D printing is only suitable for making small products, general electronic products, and other things, or as a design company, making a volume model is possible. For example, we specialize in making precision parts, and it seems that it is not feasible to use 3D printing. The reason for this is well-known, even if you can print it out, But doing post-processing on your surface is also a painful thing.

For decades, CNC machining has been a popular manufacturing process. It includes using computer-controlled machines to manufacture precise parts from raw materials. On the other hand, 3D printing is a relatively new technology that has become increasingly popular in recent years. It involves using a layer by layer addition process to create 3D objects from digital files. The question is, will 3D printing replace CNC machining in the future?

Can 3D printing technology replace CNC technology?

In an era of popular 3D printing, 3D printing of portraits, toys, and houses is overwhelming -3D printing is considered omnipotent in people’s minds. 3D printing can print everything, everything can be printed in 3D, but is this actually the case?

Let’s take an example to illustrate, for example, a car rear wing handboard, which is generally priced around 5K-7.5K for CN processing, but requires at least 2W for 3D printing, and its strength and performance are not as good as those produced by CNC. 3D printing is only suitable for small products, such as general electronic products, which are lightweight and have complex structures. The advantage is fast time, but the disadvantage is limited materials, and the cost of large products is high.

The advantage of CNC machining is that it has a large processing stroke, while the disadvantage is that when processing complex workpieces, it needs to be disassembled into many parts before welding; The advantage of 3D printing is that it can print complex parts, but the disadvantage is that printing large items is expensive. Therefore, when making parts, these two processing methods can complement each other, rather than using a single processing method.

Advantages of 3D Printing

One of the main advantages of 3D printing services is the ability to create complex geometries that would be difficult or impossible to achieve with CNC machining. This is because 3D printing builds up the part layer-by-layer, allowing for intricate shapes and designs. Another advantage is that 3D printing allows for the production of small batches of parts at a lower cost than CNC machining. This is because there is no need for expensive tooling, which is required for CNC machining. 3D printing can also create parts with internal cavities or hollow structures, which would be difficult to produce with CNC machining or other traditional manufacturing processes.

Advantages of CNC Machining

CNC machining, on the other hand, has several advantages over 3D printing. One of the main advantages is the ability to create parts from a wide range of materials, including metals, plastics, and composites. CNC machining services is also capable of producing parts with much higher accuracy and surface finish than 3D printing. CNC machines are also much faster than 3D printers, making them more suitable for high-volume production. Additionally, CNC machines can be used to create parts with threads or other features that require high precision and accuracy.

Which is better or worse, 3D printing or CNC machining?

How to choose between the two mature model production processes, 3D printing and CNC machining?

Differences in process principles

3D printing is an additive manufacturing technology, while CNC machining is an additive manufacturing technology. In order to manufacture the same object, 3D printing reduces waste through design, as this technology only requires the materials needed to manufacture the workpiece.

In CNC, you need a material that is at least the same size as the block – a large amount of material must be removed and usually cannot be recycled.

Differences in processing materials

CNC machining is mainly focused on sheet metal. Due to factors such as batch size and processing quality, the consistency of the materials is poor, and there are no performance parameters available for customers to refer to.

The plastic wire and liquid photosensitive resin used for 3D printing are both imported materials, and each material has specific performance parameters as a reference for selection.

The commonly used materials for online CNC machining include ABS, PC, POM, PP, PMMA, bakelite, aluminum alloy, zinc alloy, stainless steel, etc. It covers most types of products in the market, especially the types of metal materials.

Handling differences in model structure

3D printing simply cuts the model into thin slices with N or more layers, just like building a house, with materials stacked layer by layer. Therefore, 3D printing can handle complex surfaces and parts with anisotropic structures, forming them in one go.

However, the forming size of 3D printing is limited by the pallet, and large samples above 1.4m cannot be processed at once.

CNC machining is an open machining environment, with formed dimensions larger than 3D printing. For large and simple structures, CNC has advantages.

Differences between machining speed and cost

3D printing can process multiple parts within the limited range of the tray at once, and 3D data maps can be directly imported. It can be printed immediately after startup, and there is no need for personnel to be on duty during the operation.

CNC machining only requires 2D CAD drawings and can be programmed, but the programming time is long, and only one part can be processed at a time. During the machining process, the operator needs to change the fixture design, and the processing time and labor cost are 2-3 times that of 3D printing.

From the above four comparisons, 3D printing can easily create complex structures and mixed material models; CNC has more advantages in material selection and large-scale model production. These two processing methods complement each other.

The Future of Manufacturing

3D printing is unlikely to completely replace CNC machining in the future. Although 3D printing has several advantages, CNC machining is still the preferred method for mass production of high-precision parts. However, 3D printing is likely to become a complementary technology for CNC machining.

3D printing can be used to produce complex parts with unique geometric shapes, while CNC machining can be used to manufacture parts with higher accuracy and surface finish. By combining the advantages of two technologies, manufacturers can manufacture components more efficiently and economically.

conclusion

3D printing and CNC machining are both important technologies in the manufacturing industry. Although 3D printing has several advantages, CNC machining is still the preferred method for mass production of high-precision parts

With the continuous improvement of 3D printing technology, it is likely to become a supplementary technology for CNC machining. This will enable manufacturers to leverage the unique advantages of these two technologies, ultimately achieving more efficient and cost-effective manufacturing processes.