This article discusses the factors to consider when choosing a CNC machining company in China, including experience, manufacturing capability, quality control, cost, and communication. It also highlights our company’s CNC manufacturing capabilities, quality control procedure, and surface finishing services.

How to Choose the Right CNC Machining Company in China

When it comes to choosing the right CNC machining company in China, it can be overwhelming as there are so many options available. Below are some factors to consider when selecting the right CNC machining company in China:

1. Experience and Reputation:Experience and reputation are critical factors to consider when selecting a CNC machining company in China. Choose a company that has been in business for several years with a good reputation. You can check their reputation by reading reviews and testimonials from their previous clients.

2. Manufacturing Capability:It is essential to select a online CNC machining company in China that has the capability to manufacture the products you need. Check if the company has the necessary equipment, technology, and expertise to handle your project.

3. Quality Control:Quality control is crucial when selecting a CNC machining company in China. The company should have a quality control process in place to ensure that their products meet the required standards. Check if the company has an ISO certification, which is an indication of their commitment to quality.

4. Cost:Cost is a critical factor when choosing a CNC machining company in China. Compare the prices of different companies and choose one that offers competitive rates without compromising on quality.

5. Communication and Customer Service:Choose a CNC machining company in China that has excellent communication and customer service. They should be able to answer your questions promptly and keep you updated on the progress of your project.

By considering these factors, you can select the right CNC machining company in China that will meet your requirements and deliver quality products on time.

Why Outsource CNC Machining Services to China

Outsourcing CNC machining services to China has become a popular trend in recent years. One of the main reasons is the lower cost of production in China due to the abundance of skilled labor and lower operating costs. China has a vast network of suppliers and manufacturers, making it easy to outsource CNC machining services, especially for companies looking to scale up their production.

In addition to lower costs, outsourcing CNC machining services to China provides access to advanced technology and equipment. Many Chinese CNC machining companies invest heavily in modern technology and equipment to ensure they can handle a wide range of projects. As a result, companies that outsource their CNC machining services to China benefit from faster turnaround times and high-quality products.

Moreover, many China CNC machining companies offer customized solutions to meet their clients’ specific needs. They have highly skilled engineers and technicians who can work with clients to design and manufacture products that meet their exact specifications. This level of customization ensures that the final product meets the client’s requirements and is of high quality.

Finally, outsourcing CNC machining services to China allows companies to focus on their core competencies while leaving the manufacturing process to experts. By outsourcing, companies can reduce their operating costs and increase their efficiency, allowing them to allocate resources to other critical areas of their business.

In summary, outsourcing CNC machining services to China provides several benefits, including lower costs, access to advanced technology and equipment, a vast network of suppliers and manufacturers, customized solutions, and increased efficiency. By outsourcing CNC machining services to China, companies can reduce their costs, increase their production capabilities and focus on their core competencies.

Our CNC Manufacturing Capabilities

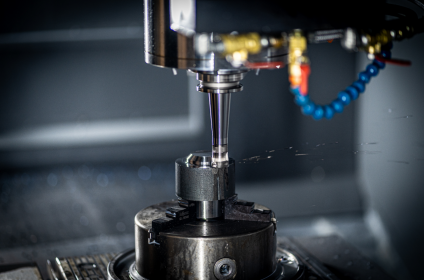

Our company has the most advanced equipment and technology to meet various CNC manufacturing needs. We provide high-precision processing and fast delivery to ensure that our customers receive the best service. If you are looking for a company that can produce high-quality CNC manufacturing products, we are your best choice.

Our manufacturing capabilities are very rich, including but not limited to the following:

- Various CNC processing such as drilling, milling, turning, cutting, etc.

- 3D printing

- Metal and plastic material processing

- Precision component manufacturing

We can customize production according to your specific requirements to ensure that our products meet your needs. Our production process is very strict, and all products must undergo multiple quality inspections to ensure that they meet high-quality standards.

Our team is composed of experienced manufacturing engineers and technicians, all of whom have many years of CNC manufacturing experience. Our team attaches great importance to customer experience, and we will do our best to ensure your satisfaction during our cooperation.

If you have any CNC manufacturing needs, please contact us, and we will serve you wholeheartedly. We believe that our high-quality products and excellent service will bring success to your business.

Our Surface Finishing Services

We offer various surface finishing services for parts, including polishing, sandblasting, spraying, anodizing, and more. We use the most advanced equipment and technology to ensure stable and reliable quality for surface treatments. We can customize production according to your specific requirements to meet your specific needs.

Our surface finishing services include:

- Polishing: We use efficient polishing equipment and technology to ensure that the surface of the parts is smooth, scratch-free, and burr-free.

- Sandblasting: We use high-pressure sandblasting machines and high-quality sand to ensure that the surface of the parts is clean and the roughness is uniform.

- Spraying: We use high-quality spraying equipment and materials to ensure that the surface coating of the parts is even, durable, and beautiful.

- Anodizing: We use high-precision anodizing equipment and technology to ensure that the coating thickness of the parts is uniform, the color is bright, and the corrosion resistance is strong.

Our surface finishing services can be widely used in machinery, electronics, automotive, medical, and other fields, providing customers with high-quality surface treatment services. If you need surface finishing services, please contact us, and we will be happy to serve you.

Our Quality Control Procedure

Quality control is critical when choosing a CNC machining company in China. We take quality control very seriously and have a strict quality control procedure to ensure that our products meet the required standards. We conduct rigorous inspections and testing for each batch of products, including visual inspection, dimension measurement, material testing, and performance testing. Our quality control procedure follows ISO standards and is continuously improved and optimized to ensure that our products are always at the highest level of quality.

Our quality control procedure includes the following steps:

- Raw material inspection: We inspect each batch of materials to ensure that they meet the requirements. We check the quality, size, and appearance of the materials to ensure their reliability.

- Preliminary inspection: We conduct visual inspections and dimension measurements for each part to ensure that they meet the requirements. We use high-precision measuring instruments to check the size and appearance of the parts to ensure that they meet the design requirements.

- Processing inspection: We conduct size measurements and performance testing for the processed parts to ensure that they meet the requirements. We use high-precision measuring instruments to check the size and performance of the parts to ensure that they meet the design requirements.

- Final inspection: We conduct final inspections and testing for each batch of products to ensure that they meet the requirements. We use high-precision measuring instruments to check the size and performance of the products to ensure that they meet the design requirements.

Our quality control procedure is one of the keys to our success. We believe that through our high-quality products and excellent service, we can bring success to your business. If you have any questions about our quality control procedure, please feel free to contact us, and we will serve you wholeheartedly.

outsourcing CNC machining services to China can provide numerous benefits, including access to advanced technology and equipment, lower costs, customized solutions, and increased efficiency. By partnering with a reliable and experienced CNC machining company in China, companies can achieve their production goals and focus on their core competencies, ultimately leading to business success.