In modern manufacturing industry, the continuous innovation of digital production technology has promoted the development of CNC machining and 3D printing technology. Whether it’s CNC machining or 3D printing, both technologies have many applications

CNC machining and 3D printing although they may seem similar, there are significant differences between the two processes.In this article we will delve into the differences between CNC machining and 3D printing.

For those who want to learn about CNC and 3D printing, here is a brief introduction.

CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled machines to remove material from a block of material. The machines use various cutting tools to shape the material into the desired form. CNC machines are highly accurate and can produce complex parts with tight tolerances. They are commonly used in the automotive, aerospace, and medical industries.

CNC machines can produce parts with high precision and accuracy, making them ideal for creating parts with tight tolerances. They can work with a variety of materials, including metals, plastics, and composites, making them versatile. However, CNC turning machining can be time-consuming and expensive, making it less suitable for small-scale production.

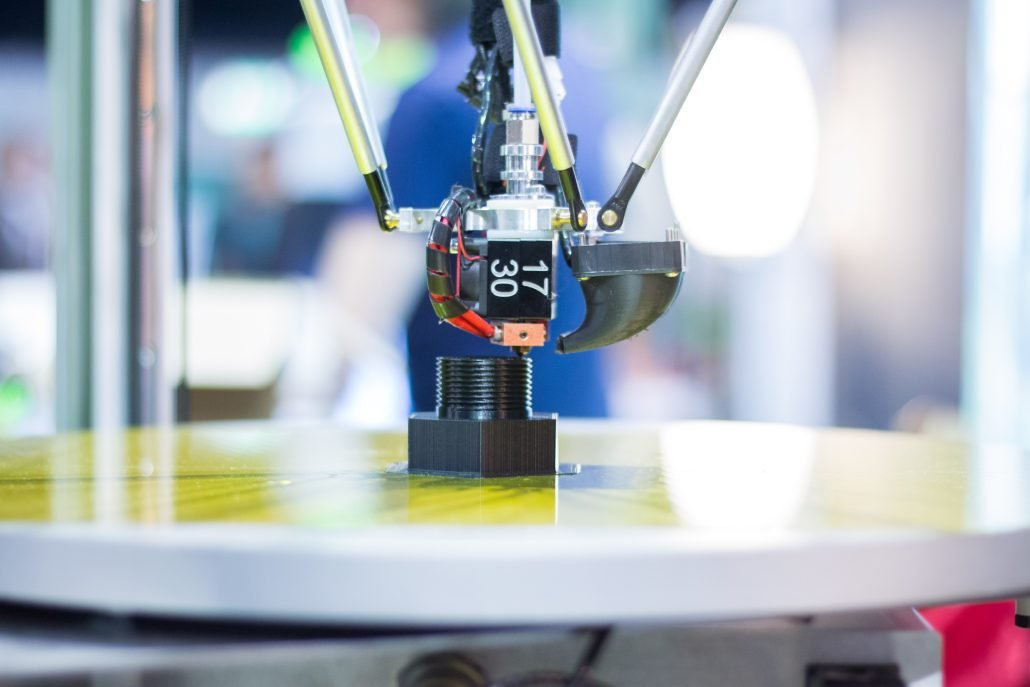

3D Printing

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by adding material layer by layer. The material can be plastic, metal, or even food. 3D printing is highly versatile and can produce customized parts quickly and at a relatively low cost. It is commonly used in the prototyping, architecture, and jewelry industries.

3D printing is ideal for creating customized parts quickly and at a relatively low cost. It can create complex internal structures, making it suitable for creating parts that would be difficult or impossible to produce with CNC machining. However, 3D printing has limitations in terms of the materials that can be used. It can only work with materials that can be melted or cured, such as plastics, metals, and ceramics.

Differences

The main difference between CNC machining and 3D printing is the way the parts are created. CNC machining removes material to create the desired part, while 3D printing adds material to create the part. CNC machining is typically faster and can produce parts with higher precision and accuracy. 3D printing is more versatile and can create parts with complex internal structures.

Another difference between the two processes is the cost. CNC machining can be expensive due to the equipment needed and the time it takes to set up and produce parts. 3D printing, on the other hand, is relatively inexpensive and can be done using a desktop printer. This makes it more accessible to small businesses and individuals.

It is important to note that both online CNC machining and 3D printing have their advantages and disadvantages. CNC machining can create parts with high precision and accuracy, making it ideal for creating parts with tight tolerances. At the same time, 3D printing can create customized parts quickly and at a relatively low cost.

CNC machining is ideal for creating high strength, high performance parts that require tight tolerances. It can work with a variety of materials and can create parts with high accuracy and repeatability. However, CNC machining is typically slower and more expensive than 3D printing, making it less suitable for small-scale production.

On the other hand, 3D printing is ideal for creating customized parts quickly and at a relatively low cost. It can create complex internal structures that would be difficult or impossible to produce with CNC machining. However, 3D printing has limitations in terms of the materials that can be used. It can only work with materials that can be melted or cured, such as plastics, metals, and ceramics.

In conclusion, choosing between CNC machining and 3D printing depends on the specific needs of the project. Factors such as the materials to be used, the complexity of the parts, and the production volume must be taken into consideration. CNC machining is ideal for creating high-performance parts with tight tolerances, while 3D printing is ideal for creating customized parts quickly and at a relatively low cost. It is important to weigh the advantages and disadvantages of each technology before deciding which one to use for a specific project.

Remember, whatever technology you choose, make sure you choose the right machines and people to run and maintain them to ensure a successful production.