This article compares two popular methods of rapid prototyping: 3D printing and CNC machining. It explains the differences between the two processes and offers a breakdown of the advantages and limitations of each. The article also explores various types of rapid prototyping and discusses how to choose the appropriate manufacturing technology.

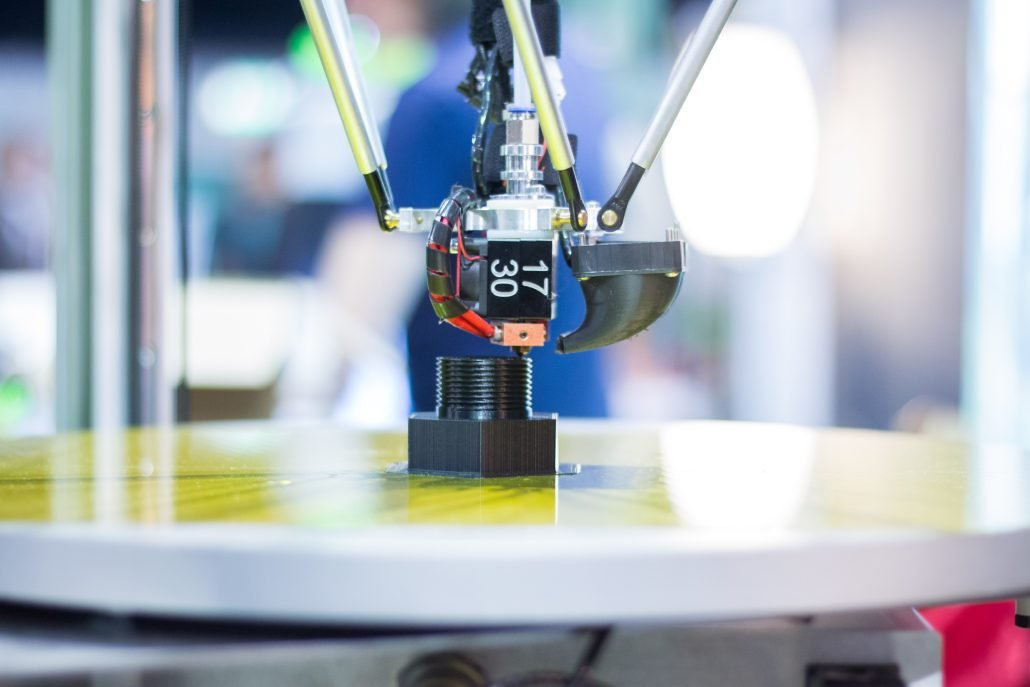

What is CNC Pototyping?

CNC prototyping is a manufacturing process that involves using computer-controlled machines to create intricate and precise parts and products. The process involves programming a CNC machine to cut, shape, and form materials to create a design. The machine uses various tools such as drills, lathes, and mills to shape the material according to the programmed design.

One of the benefits of using CNC rapid prototyping is that it can create parts with a high level of precision and accuracy, making it ideal for creating parts with tight tolerances. CNC rapid prototyping is also useful for creating parts with complex geometries, such as curved or angled surfaces, that would be difficult or impossible to create using traditional manufacturing methods. Additionally, CNC rapid prototyping can be used to create functional prototypes, allowing engineers and designers to test the fit and function of a part before it goes into production.

However, CNC rapid prototyping has some limitations. It is best suited for creating parts out of solid blocks of material, and is not well-suited for creating parts with intricate internal structures or that are hollow. Additionally, CNC rapid prototyping can be more time-consuming and expensive for creating complex parts.

CNC prototyping is widely used in industries such as automotive manufacturing, aerospace, and electronics. It allows for the creation of complex and precise parts that would be difficult or impossible to achieve using traditional manufacturing methods. CNC prototyping also reduces the amount of waste material produced during the manufacturing process, making it a more environmentally friendly option.

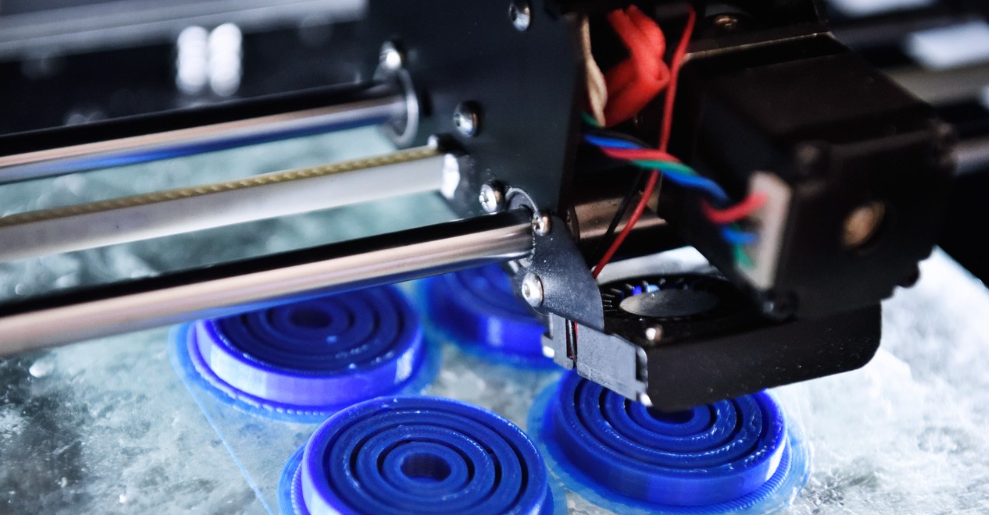

What is 3D Printing?

Online 3D printing, also known as additive manufacturing, is a process that creates a three-dimensional object by adding layers of material. 3D printers use a variety of materials such as plastic, metal, ceramics, and even food to create a finished product. The printer reads a digital file and prints out the object layer by layer. 3D printing is particularly useful for creating complex shapes and geometries that would be difficult or impossible to create using traditional manufacturing methods.

One of the benefits of using 3D printing is that it can create parts with a high level of detail and complexity, including intricate internal structures and hollow parts. 3D printing is also useful for creating parts with a high degree of customization, allowing for unique designs and shapes. Additionally, 3D printing can be a relatively fast and cost-effective method for creating complex parts, especially for small production runs.

However, 3D printing also has some limitations. It may not be suitable for creating parts with a high level of accuracy or precision, as the layers of material can cause slight imperfections in the finished product. Additionally, 3D printing may not be suitable for creating parts with high tensile strength, as the layer-by-layer process can create weak points in the material.

Is CNC Pototyping the Same as 3D Printing?

No, CNC prototyping and 3D printing are not the same. CNC (Computer Numerical Control) machining involves cutting and shaping a material using a computer-controlled machine. The machine follows a pre-programmed set of instructions to remove material from a solid block to create the desired shape.

On the other hand, 3D printing uses a printer to create a 3D object layer by layer from a digital file. The printer adds material, typically plastic or resin, layer by layer until the object is complete. 3D printing is a type of additive manufacturing technology where the object is created by adding material, while CNC machining is a subtractive manufacturing process where the material is removed to create the final product.

Although both processes can be used to create prototypes, they are fundamentally different in their approach and the materials they use. CNC machining is more suitable for creating complex parts and working with different materials, such as metals, plastics, and wood. 3D printing, on the other hand, is more suitable for creating simple parts and working with plastics and resins.

In summary, CNC prototyping and 3D printing are two different manufacturing processes that have their own advantages and limitations. Which one to use depends on the needs of the project and the desired outcome.

Difference between CNC Rapid Prototyping and 3D Printing

The main difference between CNC rapid prototyping and 3D printing lies in the manufacturing process. CNC rapid prototyping is a subtractive process, while 3D printing is an additive process. CNC rapid prototyping is best suited for creating parts out of solid blocks of material, whereas 3D printing can create parts that are hollow or have intricate internal structures. CNC rapid prototyping is typically faster than 3D printing for simple parts but can be more time-consuming for complex parts.

In conclusion, CNC rapid prototyping and 3D printing are both useful methods for creating prototypes. Which method you choose depends on the type of part you are creating and the materials you want to use. Each method has its own advantages and disadvantages, and it is important to consider these factors when selecting a manufacturing method for your project. By understanding the differences between CNC rapid prototyping and 3D printing, you can make an informed decision that will help you create the best possible prototype for your needs.

Four Types of Rapid Prototyping

Rapid prototyping is a quick and effective way to bring new products to market. There are four main types of rapid prototyping, each with its own strengths and weaknesses.

- Fused Deposition Modeling (FDM) – This type of rapid prototyping involves melting and extruding a thin filament of plastic material. The printer head moves in the X, Y, and Z directions to create the desired shape. FDM is best for creating simple shapes and is often used in the early stages of product development.

- Stereolithography (SLA) – SLA uses a laser to solidify a liquid resin, layer by layer, to create a 3D object. It is best for creating complex shapes with a high level of detail. SLA is often used for creating functional prototypes.

- Selective Laser Sintering (SLS) – SLS uses a laser to sinter a powdered material, such as nylon or metal, to create a 3D object. It is best for creating strong and durable parts with complex geometries. SLS is often used for creating end-use parts.

- PolyJet Printing – This type of rapid prototyping uses a printhead to spray liquid photopolymer onto a build platform. The material is then cured with UV light to create a solid object. PolyJet printing is best for creating models with multiple materials and colors.

Each type of rapid prototyping has its own advantages and disadvantages. Depending on the needs of your project, one type may be better suited than another. It is important to carefully consider the requirements of your project before choosing a rapid prototyping method.

3D Printing vs CNC Machining Rapid Prototyping:Which is Cheaper?

Rapid prototyping is an essential process in the world of manufacturing. It involves developing a prototype quickly and cost-effectively, allowing manufacturers to test and refine their designs before beginning mass production. Two popular methods of rapid prototyping are 3D printing and CNC machining. But which one is cheaper?

Although both methods are used to create prototypes, their costs differ. Generally, 3D printing is less expensive than CNC machining because it doesn’t require a lot of manual intervention or extra equipment. Additionally, the materials used in 3D printing are typically less expensive than the materials used in CNC machining.

However, this is not always the case. If you need to produce a large number of prototypes or require the use of high-end materials, then CNC machining may be more cost-effective than 3D printing.

In summary, the cost of rapid prototyping using 3D printing and CNC machining depends on the specific needs of your project. It’s important to consider factors such as the quantity of prototypes required, the complexity of the design, and the materials needed before deciding on which method to use.

Overall, both 3D printing and CNC machining have their own advantages and limitations when it comes to rapid prototyping. 3D printing is best suited for creating simple designs and is perfect for producing small batches of products. It is also capable of creating very complex shapes and highly customized products. However, it is generally slower than other manufacturing technologies and the materials used are often not as strong, making it unsuitable for manufacturing parts that require high strength.

On the other hand, CNC machining is more suitable for creating complex parts and working with different materials, such as metals, plastics, and wood. It is also faster and more precise than 3D printing, making it ideal for mass production. However, CNC machining is more expensive than 3D printing and requires skilled operators to run the machines.

In conclusion, both 3D printing and CNC machining can be used for rapid prototyping, but the choice of which one to use depends on the specific needs of the project.

How to Choose the Right Manufacturing Technology?

Choosing the appropriate manufacturing technology involves considering multiple factors, including:

- The type and quantity of products needed

- The materials and costs required for the products

- Manufacturing time frame and delivery time

- Precision and quality requirements during the manufacturing process

If a small quantity of complex-shaped products needs to be manufactured, then 3D printing may be a better choice. If a large number of products need to be manufactured, or high-strength materials need to be used, then CNC turning machining may be more suitable.

Before deciding which manufacturing technology to use, it is recommended to conduct some trial production to ensure that the selected technology can meet project requirements.

Overall, choosing the appropriate manufacturing technology requires considering multiple factors, including product type, quantity, materials, and costs. By understanding the pros and cons of different manufacturing technologies, the most suitable technology for individual needs can be selected.

FAQ

Both 3D printing and CNC machining are effective for rapid prototyping, but the best process depends on the specific requirements of the project. If the project requires a small quantity of complex, customized parts, 3D printing is likely the better option. If the project requires a large quantity of parts with a high degree of accuracy and precision, CNC machining may be the better choice.

The costs of 3D printing and CNC machining vary depending on the complexity of the project, the materials used, and the quantity of parts produced. In general, 3D printing is more cost-effective for small quantities of complex, customized parts, while CNC machining is more cost-effective for larger quantities of parts.

CNC machining is typically the better option for production parts because it can produce parts with a higher degree of accuracy and precision, and can work with a wider range of materials. However, 3D printing may be a viable option for low-volume production runs of complex parts.

Yes, 3D printing and CNC machining can be used together to create hybrid parts that take advantage of the strengths of both processes. For example, a part could be 3D printed to create the general shape, and then CNC machined to create fine details and achieve a higher degree of accuracy and precision.

In conclusion, both 3D printing and CNC machining have their own advantages and limitations when it comes to rapid prototyping. The choice of which method to use depends on the specific needs of the project, including the quantity of prototypes required, the complexity of the design, and the materials needed. By understanding the pros and cons of different manufacturing technologies, the most suitable technology for individual needs can be selected.