CNC machining is a process that requires precision and accuracy. It is a crucial process for various industries like aerospace, automotive, and medical. Selecting a reliable and experienced manufacturer is crucial for the success of your project. Here are some tips to help you select the right CNC machining manufacturer to work with.

Experience and Expertise

When selecting a CNC machining manufacturer, consider their experience and expertise in the industry. A manufacturer with years of experience and a team of skilled professionals will likely deliver high-quality products that meet your specifications. You can also check their portfolio to see if they have experience in producing parts or products similar to yours.

It is important to note that experience is not just about the number of years the manufacturer has been in the industry but also the kind of projects they have worked on. A manufacturer with experience in producing similar parts or products to yours will be better equipped to handle your project with precision and accuracy.

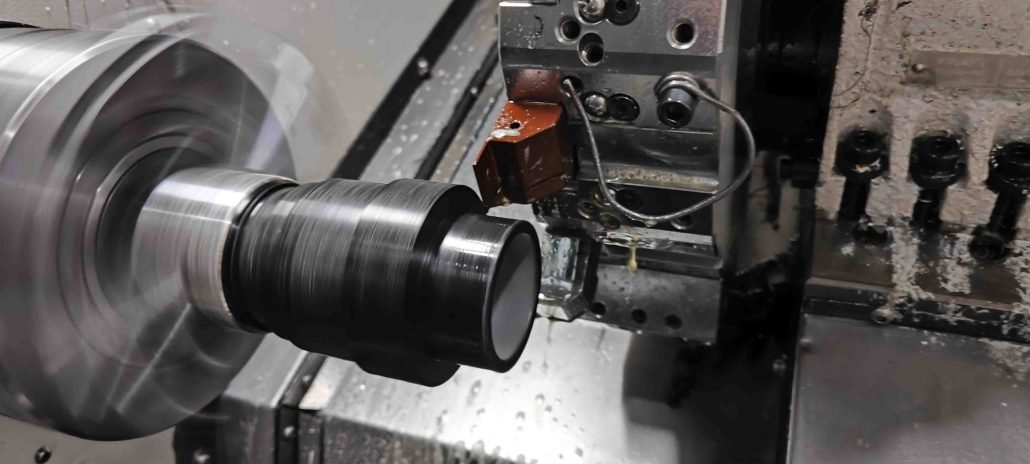

Equipment and Technology

The quality of CNC machining largely depends on the equipment and technology used in the process. Make sure the manufacturer you select has the latest and most advanced equipment to produce the parts or products you require. This will ensure that the final product is of high-quality and meets your specifications.

Apart from the quality of the equipment, it is essential to consider the maintenance and servicing of the equipment. The manufacturer should have a dedicated team to maintain and service their equipment regularly to ensure that they are functioning optimally.

Quality Control

Quality control is an essential aspect of CNC machining. The manufacturer you select should have a robust quality control system in place to ensure that the parts or products meet your specifications. This includes inspection and testing procedures to identify any defects and ensure that the final product is of high-quality.

It is important to ask the manufacturer about their quality control procedures and if they have any certifications to back them up. Certifications like ISO 9001:2015 indicate that the manufacturer has a robust quality control system in place.

Cost

Cost is an important consideration when selecting a CNC machining manufacturer. You should compare the prices of different manufacturers and select one that offers competitive rates without compromising on the quality of the final product.

However, it is important to note that the cheapest option may not always be the best. Cheaper rates may be an indication of compromised quality or lack of experience. It is essential to find a balance between cost and quality to ensure that you get the best value for your money.

Customer Service

A good CNC machining manufacturer should provide excellent customer service. They should be responsive to your inquiries and provide timely updates on the progress of your project. They should also be willing to work with you to address any concerns or issues that arise during the production process.

It is important to ask the manufacturer about their communication channels and response times. A manufacturer who is difficult to reach or slow to respond may cause delays in your project.

In conclusion, choosing the right CNC machining manufacturer requires careful consideration of their experience, expertise, equipment, quality control, cost, and customer service. By following these tips, you can select a reliable and experienced manufacturer to work with on your project.

China CNC Machining Service

Are you looking for a reliable and affordable CNC machining service in China? Look no further than our company!

We specialize in CNC machining for a variety of industries, including automotive, aerospace, medical, and more. Our state-of-the-art equipment and experienced technicians ensure high-quality parts that meet your exact specifications.

We offer a wide range of machining services, including milling, turning, drilling, and grinding. Our team can work with a variety of materials, including aluminum, steel, brass, copper, and plastics.

In addition to our machining services, we also offer value-added services such as surface finishing, heat treating, and assembly.

At our company, we pride ourselves on delivering exceptional customer service and fast turnaround times. Contact us today to learn more about our CNC machining services in China.