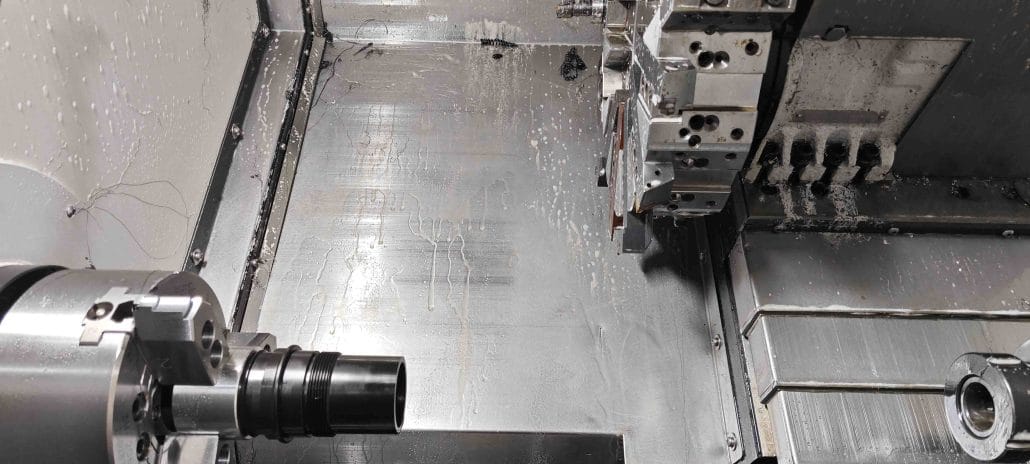

CNC machining is a modern manufacturing process that uses computer software to control the movement and operation of machinery, which is used to manufacture products. This technology has greatly revolutionized the manufacturing industry and has been widely adopted across various industries, due to its ability to produce parts to exact specifications, ensuring high quality and meeting the required standards.

Automotive Industry

The automotive industry is one of the major industries that uses CNC machining. It is used in the manufacturing of various parts, such as engine components, gears, and suspension systems. CNC machine parts are used to produce these parts with greater precision, ensuring that the parts are of high quality and meet the required standards. CNC machining has also reduced the turnaround time and increased the efficiency of the manufacturing process, making the automotive industry more competitive.

Aerospace Industry

The aerospace industry also heavily relies on CNC machining technology. The industry uses CNC machines to manufacture parts for aircraft, rockets, and satellites. These machines are used to produce parts that are critical to the safety and performance of the aircraft, such as engine components and landing gear. The use of CNC machining in the aerospace industry ensures that the parts are made with great accuracy and precision, which is necessary in ensuring the safety of the aircraft.

Medical Industry

CNC machining is also used in the medical industry. The technology is used to manufacture medical devices, such as prosthetics, implants, and surgical instruments. CNC machines are used to produce these devices to exact specifications, ensuring that they are safe and effective for patients. The use of CNC machining in the medical industry has greatly improved the quality of medical devices and has contributed to better patient outcomes.

Electronics Industry

The electronics industry also heavily relies on CNC machining technology. CNC machines are used to produce components for electronic devices, such as circuit boards and electronic enclosures. These machines are used to produce these components to exact specifications, ensuring that they are of high quality and meet the required standards. The use of CNC machining in the electronics industry has greatly improved the quality of electronic devices, making them more reliable and efficient.

In conclusion, CNC machining technology has transformed the manufacturing industry and has a wide range of applications across various industries. Its ability to produce parts to exact specifications has made it an indispensable tool in the manufacturing process. CNC parts machining has greatly improved the quality of products across various industries, making them more reliable, efficient, and safe.

FAQ

CNC Machining has a variety of benefits, including:

Produces parts to exact specifications

Ensures high quality and meets required standards

Reduces turnaround time and increases efficiency

Improves safety and performance of products

Contributes to better patient outcomes

CNC Machining is used to manufacture a wide range of products, including but not limited to:

Engine components

Gears

Suspension systems

Aircraft parts

Medical devices such as prosthetics, implants, and surgical instruments

Electronic components such as circuit boards and electronic enclosures

CNC machining has greatly improved the manufacturing industry by:

Making the manufacturing process more efficient

Improving the quality and safety of products

Reducing turnaround time

Increasing competitiveness

CNC machining has transformed the production process of various industries, which has contributed to better quality, efficiency, and safety in the products produced.