If you’re looking for a manufacturing process that can create high-quality, detailed, and complex parts quickly and efficiently, then custom injection molding might be the solution you’ve been searching for.

In this article, we’re going to take a deep dive into what custom injection molding is, how it works, and what benefits it offers. And whether you’re an entrepreneur, a product designer, or an engineer, we’re confident that you’ll find this guide informative, persuasive, and professional.

Overview of Injection Molding

Injection molding is a manufacturing process that involves injecting molten material into a mold cavity. The molten material is typically a plastic polymer, but it can also be metal, ceramic, or composite materials. The mold is designed to shape the material into the desired form, which can range from a simple cup to a complex automotive component. Once the material has solidified and cooled, the mold is opened, and the finished product is ejected.

There are different types of injection molding processes, but they all follow the same basic principle. The molding technique used depends on the material being molded, the complexity of the part, and the required tolerances. The most common processes are:

- Thermoplastic Injection Molding: This process uses a thermoplastic polymer that can be melted and solidified repeatedly. The material is heated until it becomes molten and then injected into the mold cavity. Once it has cooled and solidified, the part is ejected.

- Thermoset Injection Molding: This process uses a thermoset resin that can only be cured once. The material is heated until it becomes liquid and then injected into the mold cavity. A chemical reaction occurs as the resin cures, forming a solid part.

- Reaction Injection Molding (RIM): This process involves mixing two liquid components and injecting them into the mold cavity. The resulting reaction causes the material to solidify and form the finished part.

- Structural Foam Injection Molding: This process involves adding a blowing agent to the molten material, which creates a cellular structure as it solidifies. This technique is used to produce large, lightweight parts with high strength-to-weight ratios.

What Is Custom Injection Molding?

At its core, injection molding is a manufacturing process that involves injecting molten material into a mold cavity to create complex parts and components. This process is commonly used in the production of plastic parts for a wide variety of industries, including automotive, medical, aerospace, and consumer goods.

Custom injection molding takes this process one step further, by providing a bespoke and tailored approach to part production. With custom injection molding, designers and engineers can create parts that are unique to their specific application, with features and characteristics that are tailored to their needs.

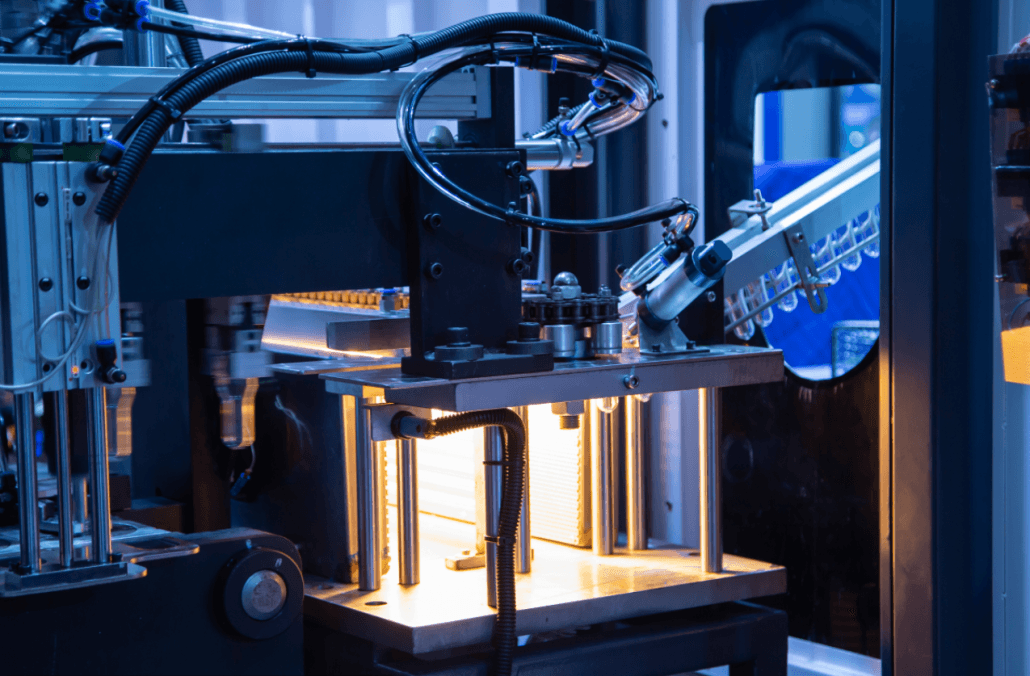

Custom injection molding is a highly precise and efficient manufacturing process that uses computer-controlled injection machines to precisely control the flow and temperature of the molten material. This allows for precise and repeatable manufacturing of complex parts that meet tight tolerances and specifications.

How Does Custom Injection Molding Work?

The custom injection molding work process typically begins with the design and prototyping of the part in question. This design is then transformed into a mold, which is typically made from metal and is designed to withstand the high pressure and temperatures involved in the injection molding process.

Once the mold has been created, the molten material is injected into the mold cavity, where it flows and cools to create the final shape of the part. The part is then ejected from the mold, and any excess material is trimmed away, leaving a finished and polished product.

What Are the Benefits of Custom Injection Molding?

Custom injection molding offers a wide range of benefits over other manufacturing processes. These benefits include:

- Precision: Custom injection molding offers a high level of precision and accuracy, allowing for the creation of complex parts with tight tolerances and specifications.

- Speed: Custom injection molding is a highly efficient process that can create complex parts quickly and efficiently, reducing production times and costs.

- Versatility: Custom injection molding can be used to produce a wide range of parts and components, with varying sizes, shapes, and materials.

- Cost-effectiveness: Custom injection molding is a cost-effective manufacturing process that can produce large numbers of parts quickly and efficiently, reducing production costs.

- Quality: Custom injection molding produces high-quality parts with a smooth surface finish and excellent material properties, ensuring long-lasting durability and performance.

In conclusion, custom injection molding is a highly versatile and efficient manufacturing process that offers a range of benefits over other manufacturing processes. And whether you’re an entrepreneur looking to create a new product, a product designer looking to bring your idea to life, or an engineer looking for the best manufacturing solution, custom injection molding is definitely worth considering.