For businesses looking to make high-quality plastic products, it is essential to find the right plastic injection molding company in Ohio. But with so many choices, evaluating and choosing the right one can be overwhelming. You want to work with a supplier who understands your needs, has the expertise to produce quality parts and can deliver on time on budget. In this article, we will guide you through the process of evaluating plastic injection molding suppliers so that you can make informed decisions and be confidence in your choice. Let’s get started!

Why Choose Longsheng For Your Plastic Injection Molding Needs?

In Longsheng, we focus on customized injection molding services to help enterprises of all sizes and industries create high quality plastic products. With over 20 years of experience in the injection industry we have the knowledge and expertise to meet all your plastic injection needs. With the help of our state-of-the-art technology and equipment, and adhere to the quality commitment, we ensure that every products we provide our customers are of high quality and accurate.

Plastic material used for injection molding

In Longsheng, our plastic injection molding service provides a variety of materials with their own characteristics and properties to meet different application needs. These materials include, but are not limited to:

| Thermoplastics | Thermosets |

| ABS | Epoxy Resin |

| PPE/PS | Silicone Rubber |

| PETG | PTFE |

| Nylon | Polyester Resin |

| Polypropylene | Phenolic Resin |

| PMMA (Acrylic, Plexiglas) | Glass-Fiber Reinforced Plastics |

Specific Material Examples

Within the wide range of materials used for injection molding, certain plastics stand out due to their specific properties and wide applications. Let’s understand their unique characteristics, common uses, and injection molding considerations together through the following content, which can guide us in selecting the most suitable materials for specific applications.

Polyethylene (PE)

As the most common plastic in the world, PE is praised for its toughness, flexibility, and resistance to chemicals and moisture. It is often used for packaging films, bags, bottles, and containers. However, when using PE for injection molding, attention must be paid to its high shrinkage rate and low UV resistance, which may affect the design and lifespan of the molded components.

Polypropylene (PP)

PP is renowned for its excellent chemical stability, wear resistance, and fatigue resistance. It is widely used in automotive components, household goods, and medical equipment. However, due to its high melting point and crystal structure, PP requires special attention during injection molding, such as controlling the melting temperature and managing the cooling process.

Polyvinyl Chloride (PVC)

PVC is one of the most commonly used thermoplastic materials and is widely used due to its high hardness and good flame retardancy. For example, it can be seen in door and window frames, pipelines, and non food packaging. However, handling PVC may release toxic smoke, so it is necessary to pay attention to ventilation and safety protection.

Polystyrene (PS)

PS is a lightweight and economical option commonly used for making disposable products such as tableware and containers. It may be crystal transparent, making it an ideal choice for food packaging and Laboratory equipment. However, its brittleness and weak resistance to ultraviolet radiation and harsh weather conditions limit its use in outdoor applications.

Polyethylene Terephthalate (PET)

PET is a versatile plastic with excellent chemical resistance, dimensional stability, and electrical insulation properties. It is widely used in soft drink bottles, food packaging and Synthetic fiber. However, it should be noted that PET can absorb moisture from the environment, which may affect the molding process.

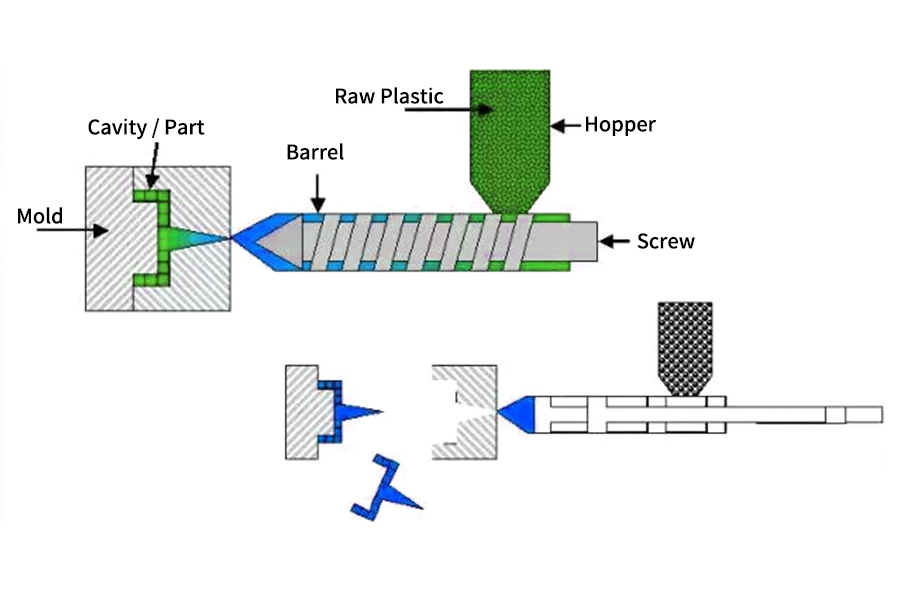

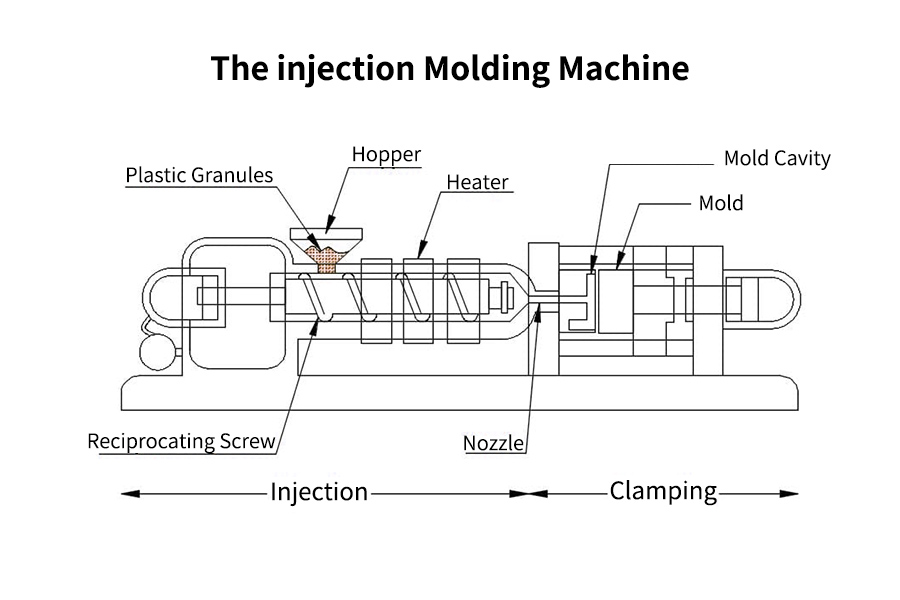

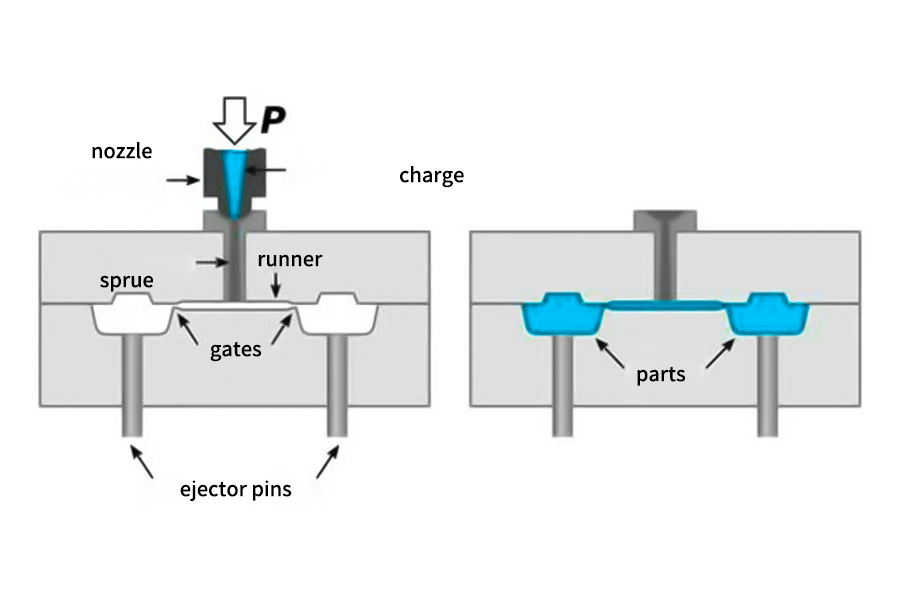

Our Injection Molding Processes

1.Request Parts Quotation

By uploading your design file to request a quote, our engineers will provide a response within 2 hours and start your project.

2.DFM Feedback

Conduct a feasibility review of your design to ensure that I, Moen, can produce functional molds that meet your requirements.

3.Mold Flow Analysis

Using mold flow analysis software to predict the flow and mode of action of molten materials within the mold can help improve and ensure the quality of the parts.

4.Part Mold Production

Start producing mold tools according to your requirements.

5.T1 Sample Verification

Before starting the production of plastic parts, we provide T1 samples for customer inspection to ensure the accuracy and quality of the parts.

6.Low Volume Production

After the sample trial production is completed, small batch production will begin. We utilize advanced processing technology to efficiently produce plastic parts.

7.Quality Control

We conduct strict inspections on the functionality, size, and appearance of plastic parts to ensure that they meet your specifications and requirements.

8.Delivery

After strict inspection, we will deliver your injection molded parts to you as soon as possible.

Your Trusted Team Of Professionals

Do you want to transform your innovative thinking into specific products? In the plastics industry, we provide not only technical services, but also a way to build close relationships with our customers. We are the service provider of plastic injection molding that you can fully trust. We can provide the best quality service to our customers at any time. With our excellent expertise and top customer service, we have the ability to help you make plastic products with a unique design. Whether you want to be personalized or mass-produce, we have the ability to meet all your needs.

Multi-material processing capacity

- We have the ability to deal with all kinds of materials, no matter what material parts processing, we can provide professional service solutions.

Provide personalized and customized services

- What you need, what our team customized for you, must package you satisfied.

No minimum order volume

- This unrestricted ordering of plastic molded parts helps to increase efficiency and reduce production costs, thus making your production process more competitive.

Fast delivery

- Our production process is efficient and flexible, which can ensure the timely completion of customer orders and meet the needs of emergency projects.

What To Notice When Looking For Companies In Ohio

There are several important factors to consider when choosing plastic injection molding companies in Ohio. Before identifying a supplier, here are some key considerations:

| main points | illustration |

| Production capacity | Longsheng has more than 20 years of working experience, serving more than 250,000 customers, and the turnover time of the design feedback is only a few hour. |

| Equipment and technology | Longsheng uses advanced injection molding equipment, mature team technology. |

| Material selection | The company has a rich selection of materials, including medical grade plastics, engineering plastics, etc. to meet different application needs. |

| Quality inspection process and standards | The company’s quality inspection process is very perfect. In Longsheng, we have a complete quality management system, and we have obtained the ISO 9001:2015 certification |

| Customized production | through our professional technology and quality service, to help you achieve a unique plastic products. Whether you need individual customization or mass production, we can meet your needs. |

| Delivery time | Our plastic injection process produces custom prototypes and end-use plastic parts for up to 3 days. |

| Cost and quotation | We offer free injection molding quotation, and our injection molding service can help you save you time and money in product development. |

| Environmental protection and sustainability | The company’s production process complies with environmental regulations. |

| After-sales service | We provide technical support and solutions for the after-sales service, and the company can timely respond to and solve the problems after the delivery, which absolutely makes you have a pleasant experience. |

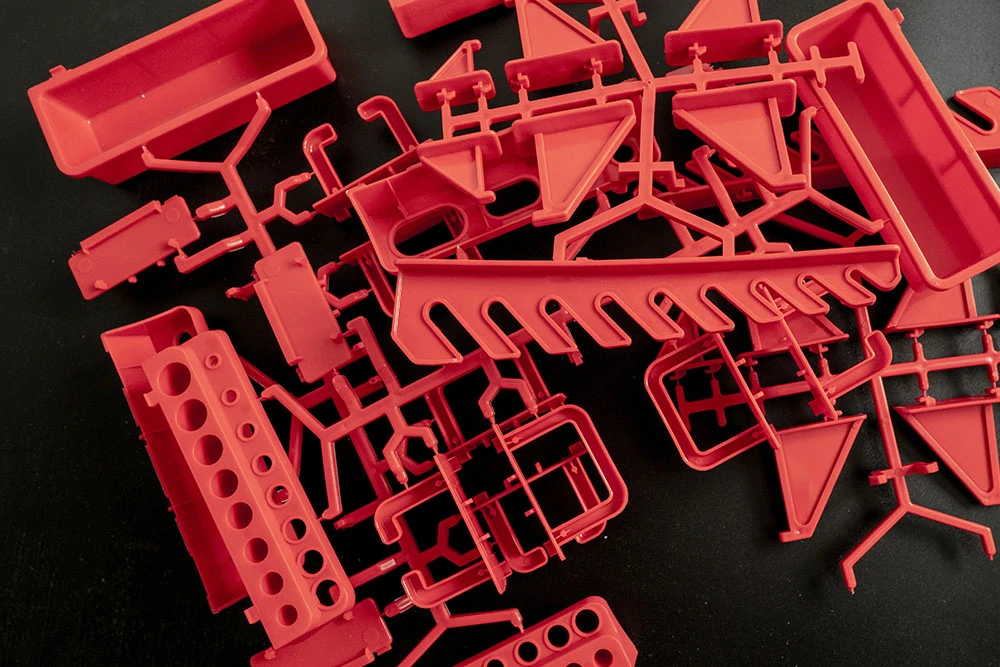

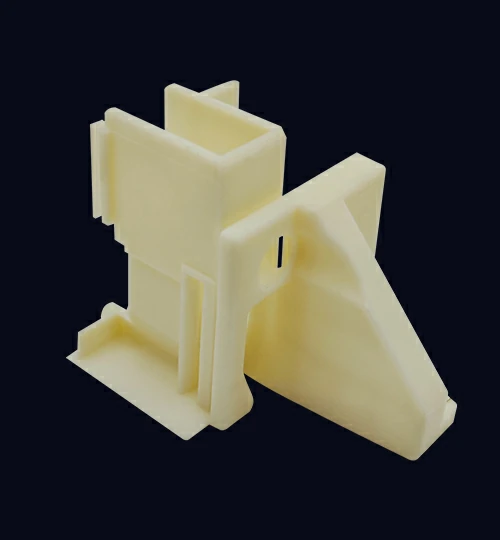

Longsheng’s injection molding parts gallery

Check out Longsheng’s rich gallery, which shows some of his finished injection molding parts, and believe that Longsheng will create your plastic injection molding project according to your strict specifications.

Conclusion

Finding the right plastic injection molding company in Ohio may be a challenging decision, but by considering the above factors, you can choose to believe in Longsheng, Longsheng must give you a satisfactory answer. In Longsheng, we are user-centered and do the best of our team to maximize customer satisfaction. If you are looking for a plastic injection molding company in Ohio, please contact us immediately to discuss your project needs.

FAQs

How to judge the technical ability and equipment level of an injection molding company?

First, you can ask the company about its equipment, including the brand, model, old and new degree of the equipment, etc. Secondly, you can ask to visit the company’s production site, and personally observe the operation situation and production process of the equipment. In addition, you can view the company’s past project cases and customer feedback to see whether its technical capabilities and equipment level meet the requirements.

How to ensure the product quality of the injection molding company?

Injection molding companies can be required to provide the certification information of their quality management system, such as ISO 9001. In addition, you can ask if the company has a strict quality testing process and ask you to view the relevant quality inspection reports. During the process of cooperation, the company can be regularly asked to provide samples for testing to ensure that the product quality meets the requirements.

How to compare and choose the quotation of the injection molding company?

After collecting the quotations of several injection molding companies, a comprehensive comparison is needed. Not only to consider the price factor, but also to consider the company’s technical ability, equipment level, product quality, delivery time and other factors. In addition, attention needs to be paid attention to the terms and details of the contract to avoid later disputes. In the final choice, we should make decisions according to our own needs and budget and comprehensive consideration of various factors.

How to establish a good cooperative relationship with the injection molding company?

The establishment of a good cooperative relationship requires the joint efforts of both sides. First of all, we should maintain close communication and exchanges to solve problems arising from cooperation in a timely manner. Secondly, we should trust and respect each other, and abide by the contract terms and commitments together. In addition, regular cooperative evaluation and feedback mechanisms can be established to identify problems and improve them in a timely manner. Through long-term cooperation and accumulation, a stable and mutually beneficial cooperative relationship can be established.