Welcome to Longsheng Technology’s blog! CNC milling as one of the extensive functions of CNC precision machining, is currently an important technology widely used in the modern manufacturing industry, in the production of complex parts, CNC milling is an essential process, this process helps to manufacture precision parts for many industries, if you are not familiar with it, Then this blog of Longsheng technology website will introduce the concept, application and working principle of milling process for you to better understand and master this technology.

During milling, the tool is moved across the surface of the workpiece to remove material and create the desired shape. CNC milling machines use many types of cutters, including drill bits, end milling cutters, ball head cutters, and cylindrical cutters. They can be used for cutting, drilling, groove machining, contour machining and other machining methods.

Tool rotation will depend on the type of CNC milling machine and its complexity. Most CNC milling parts can achieve high tolerances between +/-0.001 “and +/-0.005”. Some machines can even achieve tolerances as high as +/-0.0005 inches.

CNC milling process concept

CNC milling is a high-precision machining technology that uses a rotating tool to cut a workpiece, often used to make complex parts. In the milling process, materials are cut to the desired shape, size and surface quality. It is usually designed and simulated in three dimensions on a computer to ensure the quality and accuracy of the final product

CNC milling concept

CNC milling can help enterprises improve production efficiency and reduce production costs. This is because it can reduce the labor demand of workers while reducing the waste of materials and energy. The technology is attractive to companies looking to increase productivity and reduce costs.

Before starting to use CNC milling technology, companies need to choose the right machines and tools for their needs. These devices must be able to meet production and quality requirements while being highly reliable and maintainable. When choosing equipment, you should also consider your company’s budget and production cycle.

CNC milling process

Generally speaking, the process of CNC milling can be divided into the following steps:

Design CAD model

CNC milling requires a computer and CAD software to design the model. Engineers use CAD software to create accurate 3D models and design them into programs that CNC milling machines can recognize.

The operator will also need technical engineering drawings containing the following information:

Dimensions and key features of parts

tolerance

Construction line

Thread indication

Finishing preference

Choose the right tools and materials

Before you start milling, you need to select the appropriate tool and material. The type and size of the cutter can affect the speed, accuracy and surface finishing of the milling, so great care must be taken in choosing the cutter. Again, it is important to choose the right material because different materials require different cutting parameters.

Program input CNC milling machine

After designing the model and selecting the tool and material, you need to enter the CNC milling machine. This process is to convert CAD models into G-code language that can be recognized by milling machines. G-code is a CNC machine programming language used to direct machines to carry out machining operations.

Milling operation

As mentioned earlier, CNC milling uses a rotary tool that cuts off chips when it touches the work piece. The continuous rotation of the tool gives the desired shape. The process may involve different operations depending on the type of raw material and the desired shape of the final product.

The first few operations use larger tools to carve the material and get a general shape. The replacement tool will then help create more precise machined parts. Precision CNC milling is achieved in the final stages and involves unrivaled levels of surface roughness and engineering tolerances.

Finish machining

At the end of the CNC milling process, a perfect workpiece can be obtained, which can then be processed. Including excision, sandpaper smoothing, cleaning, etc. Finally, the workpiece can be inspected to ensure that its size, structure and surface quality meet requirements.

Check quality

After machining, the operator needs to conduct a series of quality tests to ensure that the final product meets the design requirements and standards.

Multiple CNC milling operations

CNC machining centers can generate multiple complex features with high precision. Such features include threads, chamferes, grooves, etc. However, various milling operations are required to create these features, such as:

Face milling

Face milling is a common milling operation that works on a flat surface to cut the desired shape and size on the surface of the workpiece. Face milling is usually done using a face milling tool. Drill bits and boring tools can also be used for face milling. For the workpiece requiring higher precision, high speed grinding scheme can be used to improve the machining efficiency.

Synchronous milling

Synchronous milling is a process that combines several CNC machine tools. They can work together to speed up production and increase efficiency. This process is usually used to manufacture large structural parts and components.

Angle milling

This is one of the best milling operations for creating grooves, chamferes, slots, and other complex features. Traditional 3-axis milling cutters use different cutters — dovetail cutters for chute or tapered cutting heads for chamfering. The axis of the tool is usually perpendicular to or in line with the cutting surface.

Vertical milling

The vertical milling operation is mainly used to make 3 D parts, such as models. Compared with face milling, vertical milling has higher machining efficiency and accuracy. At present, there are two common cutting methods: linear machining and curve machining. For different shape of the workpiece, can be selected according to the actual situation of different end milling tool.

Curve and contour milling

Curve and contour milling is also an important operation in CNC milling. Complex curves and contours can be achieved using curve and contour milling. This type of machining is often used for making models, engraving, and other precision work.

Flat milling

Also known as surface milling, this operation uses a horizontal milling machine. Thus, the tool has an axis of rotation parallel to the table. Surface milling uses different tools of different shapes and directions depending on the desired results. The combination of a wide cutter (faster feed) and a thinner cutter (faster cutting) is a cost-effective choice. It also ensures a better surface finish and a high quality final product.

Linkage milling

This is a subcategory of form milling, which uses multiple tools to create patterns at the same time. Tools usually come in different shapes, sizes, or widths. They may perform similar or different actions to create more complex features or complex parts in less time.

Hole milling

Hole milling is a special type of milling operation in which holes are cut inside a work piece or in a plate. Hole milling has the characteristics of large cutting depth, suitable for orifice and hole bottom adjustment, high precision. The commonly used hole milling bit has two kinds: cone drill and square drill. Operation should pay attention to determine the direction of milling and cutting depth, so as to avoid misoperation.

Surface milling

Surface milling technology is a kind of machining method to deal with the workpiece of three-dimensional surface. Surface milling operations often require custom tools to meet the requirements of different workpiece shapes. More technical.

Form milling

This milling operation uses special tools to create more complex Outlines. Concave and convex cutters are the most common here. They help create surface contours, rounded edges, and rounded grooves in a single cut.

chamfer

Chamfering is a milling operation used to eliminate corners and improve the durability of parts. Chamfering operation is commonly used and the machining difficulty is relatively low. At present, there are some special chamfering devices on the market, which can be better polished and polished for parts.

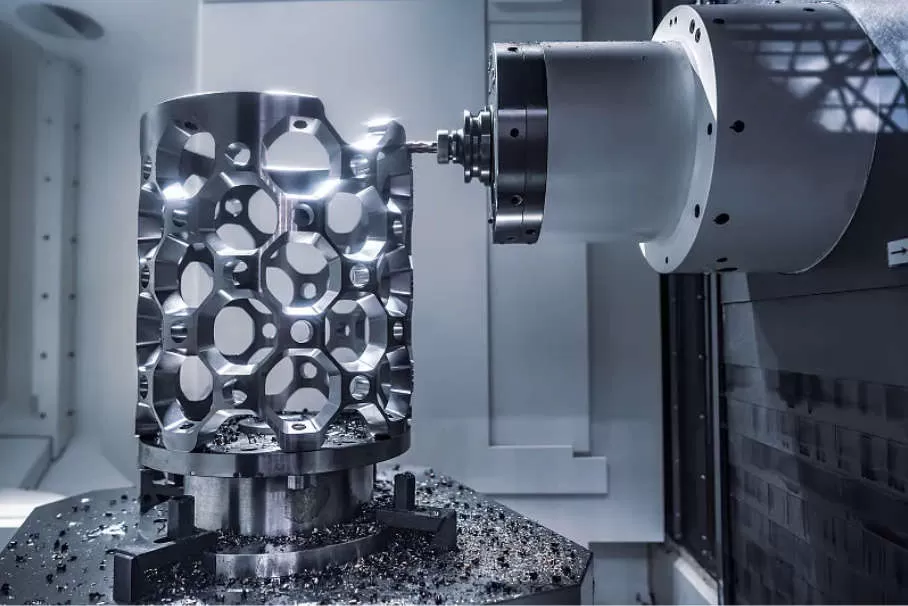

Five axis CNC milling operation

Five axis CNC machining milling operation is a CNC milling operation that can be cut at different angles. This method allows more machining to be done in a shorter time, making it more suitable for manufacturing parts and devices that require high precision and efficiency.

The advantages and disadvantages of CNC milling in parts manufacturing

CNC milling has high accuracy and efficiency in manufacturing parts. But at the same time, there are some disadvantages. Here are some of the advantages and disadvantages of this manufacturing technique.

Advantages of CNC milling

Complexity: CNC milling can help create more complex workpieces than traditional methods. The traditional method of controlling manufacturing tools is usually manual or based on the experience and skill of the salesman, which is not only more error-prone, but also requires more time and coordination. However, by using CNC milling, manufacturers can easily produce a variety of detailed and exquisite work pieces.

High efficiency: CNC milling can quickly process a large number of parts, compared with the traditional machining methods, CNC milling can greatly reduce manual intervention, with the fastest speed to manufacture high precision parts

Repeatability: Once a CNC milling procedure is established to manufacture a part, the procedure can be used over and over, no matter how many of the same parts are produced. This greatly reduces the errors in the manufacturing process and improves the reliability of the manufacturing process.

High degree of automation: CNC milling is a kind of automatic machining technology, in the process of machining does not need manual intervention, can improve production efficiency, reduce manual error and labor intensity.

High accuracy: CNC milling using automation technology, automatic control by the computer machine machining process, so the manufacturing of parts accuracy is very high, CNC milling can be accurate to 0.0001 inch or smaller distance range to achieve high precision machining results, this precision is manual intervention can not reach.

Disadvantages of CNC milling

High Cost required: CNC milling equipment is expensive, and compared to other manufacturing techniques, CNC milling is significantly more expensive in terms of the cost of buying and maintaining machines.

Single design: CNC milling is more technically demanding than traditional methods because most of the manufacturing process involves pre-written programs. This is both beneficial and harmful because it ensures consistency and accuracy of parts, but it also means that separate programs need to be written to fit a single part, and if product design or materials or dimensions are changed, programs need to be rewritten, increasing preparation and time costs.

Limited Flexibility: Compared with traditional machining methods, CNC milling has some limitations. He can’t fit all materials and shapes perfectly, and some shapes may not fit through CNC milling.

High technical threshold: CNC milling requires a certain degree of professional technology, and the production of equipment, tools and programs have higher technical requirements. Therefore, enterprises or individuals need to have the appropriate technical reserve, to be able to use and maintain CNC milling equipment.

Limited creativity to some extent: CNC milling is a highly automated process, for some personalized and low-volume production products will not meet the requirements. This means that CNC milling is not a one-size-fits-all process.

Companies should decide whether to use this technology based on their actual situation. CNC milling is the best choice for manufacturing parts with high precision, great complexity and great demand. But for small batch production or simple parts, manual machining or other machining methods can also be considered

Common materials used in CNC milling operations

In CNC milling operation, the choice of materials is very important. The strength, stiffness and wear resistance of different materials are different, which will affect the cutting effect and life of CNC milling cutter. The following are commonly used CNC milling materials:

Metal materials for milling:

Aluminium alloy

Aluminum alloy has good toughness and strength, light weight, corrosion resistance. It is often used to manufacture machine parts, aircraft components, auto parts and electronic products. In CNC milling operation, aluminum alloy has good machinability and can maintain better surface finish and precision.

Mild steel

Mild steel is a milling metal material with high plasticity and toughness. Mild steel is suitable for the production of high precision metal parts components.

Stainless steel

Stainless steel material has excellent corrosion resistance, machining properties and ductility, so it is widely used in the manufacturing of high-tech machinery and equipment, ocean engineering, food machining equipment and other fields. In CNC milling operation, the hardness of stainless steel material is high, which is easy to cause tool wear. However, because stainless steel has good machinability and high precision, it is often used in the manufacture of auto parts, precision machinery and so on.

brass

Brass is an organometallic because it is made up of different proportions of copper and zinc, among other elements. It has the advantages of good machining performance and variable color. Because it has many different alloy compositions and properties, it is suitable for a variety of CNC milling operations. Brass products are widely used in decoration and household goods manufacturing.

Titanium alloy

Titanium alloy has excellent strength and lightweight properties, is widely used in the manufacture of high-grade machinery and equipment, aircraft, nuclear industry equipment and other fields. In CNC milling operation, the cutting force of titanium alloy is large, but the hardness is also high, so the appropriate machining parameters should be selected in the operation to ensure the machining effect.

Unconventional metal

Such as tungsten, molybdenum, platinum and other materials. These materials have high strength, high hardness and good corrosion resistance. Milling unconventional metals requires the use of high-end fixtures and tools.

Plastic materials for milling:

polyurethane

Polyurethane is a high density, high strength plastic material, often used in the manufacture of high quality parts and structures. Polyurethane has excellent abrasion resistance and wear resistance. It is necessary to select appropriate tools and machining parameters to avoid heat and damage materials during milling.

ABS

ABS is a common engineering plastic with good mechanical strength, chemical resistance, heat resistance and cold resistance, which is widely used in automobile, electronic equipment, household appliances and other fields. In CNC milling operation, the hardness and softness of ABS materials are more uniform, so that the machining accuracy can be maintained well.

polypropylene

Polypropylene is a commonly used thermoplastic with excellent corrosion resistance, abrasion resistance, high strength and low temperature resistance. In addition, its low cost is very suitable for small and medium volume production. CNC milling is often used to produce machine components, pipes and daily necessities.

nylon

Nylon is a good plastic material for milling because of its high strength and toughness. At the same time, nylon has good thermal stability and wear resistance.

Polyester resin

Polyester resin is a commonly used organic plastic, consisting of organic substances such as esters and alcohols. It is characterized by good thermal insulation, flammability and good endurance. CNC milling operation is widely used in the manufacture of various plastic molds and parts

High density polyethylene

High density polyethylene has excellent wear resistance and is commonly used in the manufacture of machinery parts and industrial supplies.

PVC

PVC is a common plastic material, with strong, high temperature resistance, wear resistance and other characteristics. In milling operations, PVC can be used to make furniture, water pipes, etc.

Classification of CNC milling machines

There are many kinds of CNC milling machines on the market today, and various ways of classification. Although the basic knowledge remains the same, some modifications make each factory unique. Longsheng Technology classifies CNC milling machines according to different uses, as follows:

Classified according to machining method

CNC milling machines can be classified according to different machining types.

Three axis milling machine: also known as conventional milling machine. Refers to the common left and right, front and back, up and down three directions of machining.

Four axis, five axis milling machine: is on the basis of three axis to increase one or more rotating axis, can achieve more complex machining mode.

Engraving and milling machine: It is a CNC milling machine specially used for engraving, cutting and other fine processes.

Turning and milling compound machine: This machine can be turned using either a lathe or a milling machine.

Classification by use

According to the use can be divided into milling and drilling compound machine, five axis linkage machining center, laser machining milling machine, etc. Milling and drilling compound machine tool can complete drilling, milling and a series of machining tasks, five axis linkage machining center has the characteristics of high efficiency, high precision, laser processing milling machine is a new type of milling machine, suitable for machining high difficulty, high requirements of the workpiece.

Classification by structure

CNC milling machine between the structure is different, the main vertical milling machine, horizontal milling machine and gantry type milling machine.

Among them, vertical milling machine machining range is small, suitable for machining small workpiece, horizontal milling machine machining range is large, suitable for machining larger workpiece. Floor type milling machine and gantry type milling machine have a wider machining range, suitable for processing large, super heavy workpiece.

Classified by control system

CNC milling machine can be divided into simple CNC milling machine, standard CNC milling machine and advanced CNC milling machine according to the control system. Simple CNC milling machine has the basic control system and machining functions, the price is relatively low, suitable for beginners and small enterprises. The standard CNC milling machine has more abundant functions and higher accuracy, and is widely used in small and medium-sized manufacturing enterprises. Advanced CNC milling machine is the most comprehensive, the highest precision equipment, widely used in aviation, aerospace and other high-end manufacturing fields.

Sort by tool head

According to the cutter head can be divided into ordinary milling machine, face milling machine, gear milling machine and other three categories. Ordinary milling machine is suitable for general machining tasks, and face milling machine mainly machining plane, gear milling machine is mainly used to process a variety of gears.

Milling machine according to different classification, can cover different machining needs. According to their own needs, choose the suitable type of milling machine, can improve the machining efficiency, CNC milling machine has a wide range of applications, can be used for metal materials machining, can also be used for plastic, wood and other non-metallic materials machining

Common components of CNC milling machines

Here, we will analyze the components that make up a CNC milling machine. Although the new milling machine is somewhat complex, Longsheng Technology will stick to the traditional milling center for a proper overview. The basic components of a CNC milling machine are:

Main shaft

The spindle of a CNC milling machine is a rotary tool, which cuts and machines the workpiece. You can control the position and rotation speed of the handle. The spindle is usually driven by an electric motor and can be adjusted and adjusted by electronic control

Clamping device

The clamping device is used to hold the workpiece in place so that it does not move during machining. The clamping device usually consists of a clamping clamp or a clamping tool.

Guide rail

The guide rail is another important part of CNC milling machine. It supports the spindle and the tool, while keeping the distance between the tool and the workpiece consistent. Rails are usually made of two different materials: steel and alloy; The latter has better wear resistance.

frame

This main structure supports the machine and gives it stiffness and stability. It has a base and detachable posts. The machine headstock is an important part of the frame used to mount the spindle and prevents vibration or flutter during operation of the machine tool. This prevents machining errors and extends the life of the cutting tool.

shank

During machining, the handle is responsible for carrying the tool and ensuring its correct position and orientation. Handles are usually made of high hardness materials to make them more durable and last longer.

worktable

The worktable of CNC milling machine is the positioning and supporting parts of the workpiece. The table can be up and down, left and right and rotation and other multi-axis movement to meet different machining needs.

Tool bank

Tool library is one of the parts used to install machining tool in CNC milling machine. The tool bank is usually placed on the side of the machine bed and can accommodate a number of different machining tools. During machining, the tool library can automatically change different tools.

Feed mechanism

The feed mechanism of CNC milling machine controls the movement of workpiece and tool. The feed mechanism is usually composed of stepper motor, bracket, transmission device and control system. It can precisely control the position, speed and force in the cutting process.

plunger

You will usually find this machine component in a vertical milling machine. It is usually attached to the column that supports the main shaft. The operator can adjust the ram to occupy different positions during milling.

Control system

The control system of CNC milling machine is the brain of the whole machine. It is composed of computer, numerical control system, programming software, man-machine interface and so on. The control system can automatically control the cutting process and cutting parameters to achieve high precision machining

Bed body

CNC milling machine bed is the main structure supporting the whole machine parts. It is usually made of cast iron or steel and has high strength and stiffness. The bed must be kept smooth and stable to ensure machining accuracy and workpiece quality.

Price cost evaluation

The price of CNC milling machines and cnc milling machines depends on many factors, such as brand, model, specifications, machining needs, machining difficulty and market demand.

CNC milling machine price

Let’s look at the price range of CNC milling machines. CNC milling machines typically range in price from thousands to hundreds of thousands, depending on their size, functionality and productivity. The price of the more common CNC milling machine is usually between tens of thousands and hundreds of thousands, but the price may exceed this range, and depends on the required configuration and application.

Common CNC milling machine brands include Starfish, Haas, Mitsubishi and Philips, etc., with prices ranging from several thousand yuan to hundreds of thousands of dollars. For small and medium-sized enterprises, the price of an entry-level CNC milling machine is about 100,000 to 300,000 yuan. Of course, this is only a rough price range, the specific price needs to be based on your specific needs.

Similarly, production grade 3-axis vertical milling machines can cost between $150,000 and $300,000, while production grade 5-axis milling machines can cost over $500,000. These are rough estimates and will depend on the following factors:

Machine weight and dimensions (measured in X/Y/Z stroke)

Machine configuration (3, 4, 5 or 6 axes)

Machine speed

power

Other options available, e.g., coolant pressure, chip conveyors, automatic tool changers, robot parts loaders, etc.

Influence the price of cnc milling machine many factors, in addition to brand and model, CNC milling machine specifications will have an impact on the price. The higher the specification and the more powerful the CNC milling machine, the higher the price. Similarly, market demand will also affect the price of CNC milling machines. If the market demand is high, the price will rise accordingly, and there are additional costs to consider, such as procurement costs, transportation costs, installation costs and maintenance costs. These costs will further affect the price of CNC milling machines.

If you are considering purchasing a CNC milling machine, it is recommended that you determine your needs and budget before making a choice. At the same time, pay attention to additional costs so that you can better plan your budget.

CNC milling cost

There is no right answer to this question, because the price of CNC milling depends on a number of factors, such as the type of materials required, the hours required, the machine used, and so on. This means that you need to personalize the quote for each project. Therefore, the best course of action is to contact the CNC milling services provider to provide your design drawings or CAD files to get a more accurate idea of prices.

Whether you are looking for individual parts, or engaged in large-scale production, Longsheng technology can provide you with cnc milling machining services, do not hesitate to contact us. Longsheng Technology will provide you with satisfactory services and products to help you achieve success!

CNC milling cost calculation

Here’s a simple calculation:

Price = (material cost + man-hour cost) + auxiliary cost

Among them,

Material cost = length of raw material x width of raw material x height of raw material x material density x material price

Man-hour cost = machining difficulty coefficient x machining accuracy coefficient x start-up hours x rental coefficient

Auxiliary cost = labor cost + logistics cost + packaging cost

If you are not sure how to calculate the price, you can estimate using the formula: price of CNC milling = material cost + man-hour cost + machine operating cost.

Through the above calculation method, we can according to CNC milling machining materials, machining difficulty, machining precision and machining quantity and other factors to calculate an estimated machining price. Of course, each manufacturer’s calculation method and charge standard is different, you need to adjust flexibly according to the actual situation.

CNC milling machining application industry

CNC milling can quickly, efficiently and accurately complete the production of a variety of complex parts. The following are some of its industrial applications:

Electronic industry

CNC milling technology is also widely used in the electronics industry. In mobile phones, computers and other electronic products, need to use a large number of high-precision, miniaturized metal parts, these parts need to use CNC milling technology to complete. In addition, CNC milling is also required in some display screens and LED lights to process metal shells and structures.

Automobile manufacturing industry

Automobile manufacturing industry is a big application of CNC milling machining industry, it can not only make auto parts machining fast, accurate, efficient, but also can ensure the consistency of parts, which is very important in mass production.

Medical device industry

The application scenarios of medical devices require more stringent requirements, such as accuracy and hygiene. CNC milling technology can be used to manufacture a variety of medical devices, such as joints, bones, prostheses, and scaffolds. The production of these parts requires extremely high precision and quality control, and the widespread use of CNC milling technology enables these requirements to be met.

Mold manufacturing industry

Mold manufacturing industry is a high requirement of machining precision and efficiency of the industry, because the mold is the key to the production of parts or products. Therefore, CNC milling plays an important role in the mold manufacturing industry. The CNC milling machine can be used to process the mold quickly, with high precision, high efficiency and good consistency.

Aerospace industry

Precision and durability of parts are of Paramount importance in the aerospace industry. And CNC milling is able to provide high precision, high quality, high reliability parts production solutions. For example, the parts of the aircraft engine, the pipeline parts of the oil transmission system, etc., need to use CNC milling technology.

Shipbuilding industry

The shipbuilding industry also requires high precision and production cycle of parts. CNC milling technology can meet the needs of shipbuilding. For example, ship parts, hull parts, etc., need to use CNC machining technology to make.

FAQ

CNC milling can process a variety of different materials, including steel, aluminum, copper, plastics, wood and composite materials. Different materials need to use different machining methods and parameters, so it is necessary to make appropriate adjustments and select appropriate tools and parameters.

CNC milling is a process in which parts are manufactured using a computer-controlled numerical control machine tool. This process can be milled using a variety of materials, such as metal, plastic and wood.

CNC milling can provide higher accuracy and precision. Because the whole process is controlled by computer, the size and shape of the parts can be better controlled. In addition, it is possible to use a smaller cutter head than the traditional machine in CNC milling, so that higher accuracy and smaller machining size can be obtained.