As an important link in manufacturing industry, the relationship between surface roughness and friction has always been a hot issue in manufacturing industry. Rough surface will greatly reduce the service life and efficiency of products. In the process of friction, roughness affects the stability of the product and the size of the friction force.

For example, if two surfaces are smooth, they will only come into contact over a very small area. This leads to high pressure, which makes contact even tighter. But if both surfaces are rough, the contact area increases, making the pressure more evenly distributed. In this case, friction is reduced because there is less pressure per unit area.

So how does surface roughness affect friction? In this paper, the influence of surface finish on friction will be analyzed from the manufacturing point of view.

What is surface roughness?

Surface roughness refers to the irregularity and unevenness of the surface of an object. This parameter is critical in manufacturing because it can affect the performance and quality of a product. For example, if the surface of a machine part is too smooth, the lubricating oil will not adhere to the surface, which may lead to accelerated wear of the part due to excessive friction. However, if the surface is too rough, it can also lead to other problems, such as the accumulation of obstacles and imperfect connections.

The surface roughness is generally represented by the Ra value, the smaller the value, the smoother the surface, and the larger the value, the rougher the surface. Including roughness, waviness, vibration, flatness and so on, these indicators can effectively improve the appearance of the product quality and performance.

In the field of industrial manufacturing, surface roughness mainly affects the friction of products, so it has a direct relationship with the friction coefficient, spring elasticity, guide rail and other properties. For mechanical equipment and other products, surface roughness will also affect the stability of the product and the efficiency of conduction and other factors.

The field involved in surface roughness is very wide, covering digital painting, UV printing, household goods production, precision machinery and many other fields. Here, we share some common surface roughness evaluation parameters in technical fields.

I. Surface roughness parameters

Transverse distance S: represents the average distance between all the vertical axes of the highest point and the lowest point on the vertical axis of the surface.

Peak Rz: defined as the length of the vertical line between the highest and lowest point on a surface.

Average roughness Ra: indicates the average roughness of the surface.

Peak-valley height Rmax: indicates the difference between peak and valley on a surface.

Surface turbulence Rz1max: used to represent the surface fluctuation, namely the proportion of the fluctuation in the total data.

2.Evaluation method of surface finish

Optical instrument method: Based on diffraction theory, Fresnel principle and interference phenomenon, the optical characteristics are used to evaluate the finish.

Gravimetric method: Using the weight of the sample surface to evaluate the surface finish, suitable for testing the roughness of flat samples.

Critical distance method: A mathematical description of surface roughness that evaluates surface smoothness by measuring the change in distance between a sample surface profile and a calculated straight line.

More on solutions to surface roughness; Read the article [Cause Of Surface Roughness Of Precision Parts]

Understand the characteristics of surface friction in manufacturing

Surface friction can be described as the smoother the surface and the fewer coarse points present in the same pair of materials, the less friction. Conversely, the rougher the surface, the more rough spots and potholes appear, and the greater the friction. That’s why motorcycle tires have streaks and the brake disc, which is responsible for friction, has many small holes or bumps in the surface.

How to reduce surface friction

In manufacturing, grinding and sanding are common methods to finish surfaces to a smoother appearance and reduce surface friction. In addition, the use of lubricants and the addition of friction relievers are also commonly used to reduce surface friction. Not only that, the right surface coating can also reduce surface friction.

In some high-end machines and equipment, the use of ceramic parts, can effectively reduce the surface friction. Ceramics have high hardness and excellent surface smoothness, so the surface friction is low, wear resistance, and longer life.

The relationship between surface roughness and friction

Friction is an important concept in physics. It refers to the force caused by the interaction of two objects. Except in manufacturing there is friction; In everyday life, people can feel the presence of friction. For example, when walking, the friction between the soles of our shoes and the ground creates enough force for us to walk; When driving, the friction between the wheels and the road allows the vehicle to move.

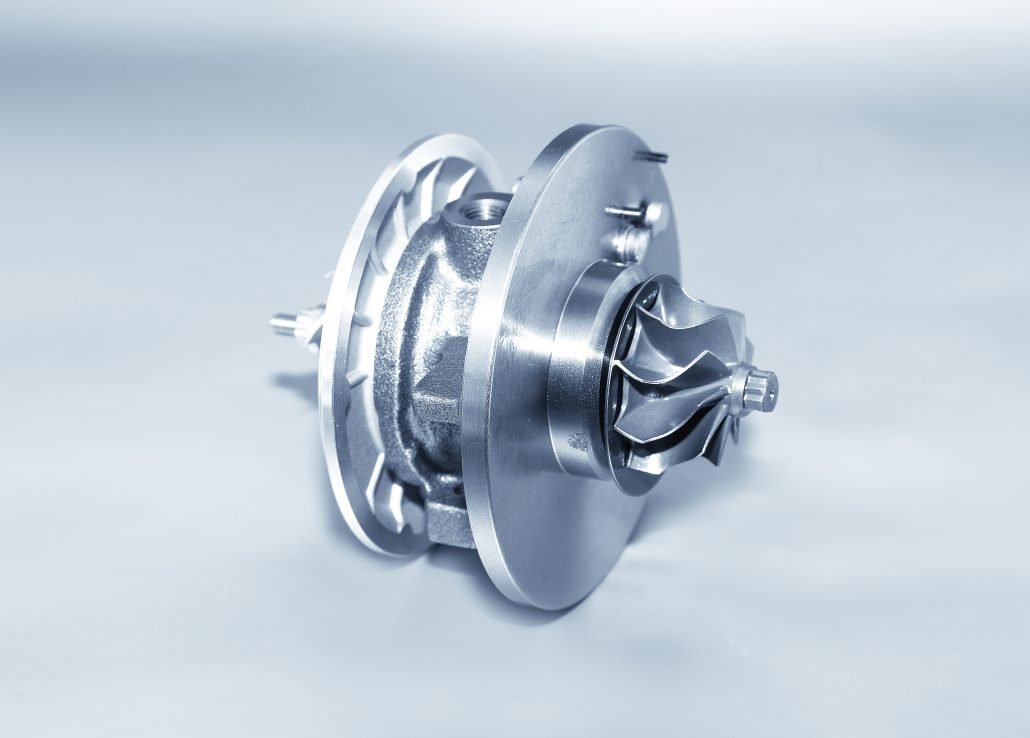

In manufacturing, to reduce friction, effective surface roughness control techniques, including precision machining, polishing and chemical etching, must be employed, and these parameters can be effectively controlled by controlling process parameters and using appropriate tools. For example, in turning, if the cutting edge is badly worn, the surface roughness will be increased, and slight scratches will also lead to increased friction on the surface. Therefore, to ensure the sharpness and smoothness of the cutting edge, to ensure that the roughness and friction of the product surface can be controlled.

Previously, conventional surface roughness parameters such as Ra, skewness, kurtosis, and peak density were considered to determine the friction between sliding objects, which increases when objects have a rough surface and come into contact with another surface. This is because the area of contact between the surfaces is larger, so the amount of friction increases. In contrast, when the surface is smooth, friction decreases. This is because the area of contact between surfaces becomes smaller and the amount of friction decreases.

Surface roughness affects the friction coefficient

When a gas, liquid, or solid passes over a surface, it is subjected to certain frictional action. The extent of this frictional action can be measured by the coefficient of friction. The roughness of the surface has a direct effect on the friction coefficient.

In fact, the greater the surface roughness, the higher the coefficient of friction. As the contact area between surfaces increases with the increase in surface roughness, the contact between surfaces becomes more incomplete and stronger, resulting in an increase in the coefficient of friction. Conversely, the smaller the surface roughness, the lower the friction coefficient.

Why is surface finish important?

If the surface roughness affects the appearance of the product. So good surface finish can make the product look more smooth, delicate, beautiful, improve the overall quality and image of the product. At the same time, a smooth surface can enhance the value and selling point of the product. In the retail world, products with more polished surfaces are often more popular because they seem to be of higher quality than other products.

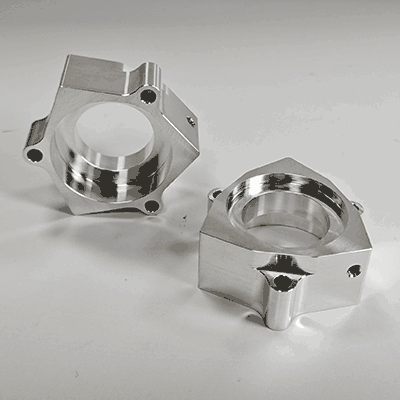

In the fields of high-tech manufacturing and precision measurement, the requirements for surface smoothness are more stringent. For example, in the aerospace industry, engine parts require good smoothness to improve engine power and efficiency. In the field of new energy vehicles, the battery casing of electric vehicles also needs to have a high surface finish to ensure the stability and lifespan of the battery.

Surface roughness plays a critical role in determining how a product reacts with its environment. The surface treatment of a product indicates the performance of its components. In addition, the roughness level may affect the effectiveness of the product.

If you want to know more about the anodizing process in surface finishing, see this article【Anodizing Finish:Applications Of CNC Machining Parts】

Surface roughness comparison diagram

How to maintain the product surface finish

A series of surface treatments are required to maintain the product surface finish, including mechanical processing, chemical treatment, electrolytic polishing, etc. The following are several common surface treatment techniques.

1.sanding

Sanding light is used by the sanding machine to flatten the surface of the object, thus achieving the purpose of improving the finish. This method is usually used for surface processing of metal materials, ceramic materials and glass materials.

2.Chemical polishing

Chemical polishing is the use of chemical treatment agent to dissolve the surface layer, so as to achieve the purpose of improving the finish. This method can be used for surface processing of materials such as metals, plastics and composites. However, chemical polishing requires the use of a large number of chemicals, causing great pollution to the environment.

3.Electrolytic polishing

Electrolytic polishing is used to peel and dissolve the surface layer by electrolysis, thereby improving the roughness and glossiness of the surface. This method can be used for surface processing of materials such as metals, plastics and glass.

For more information on surface finishing, please read our 【What Are The Various Surface Finishing Processes】

Measuring surface roughness

Surface roughness can be measured by many means. Here are some methods to help you measure surface roughness.

If you need to consider surface quality, then measuring surface roughness is an important step. Surface roughness is a measure of the geometric diversity of the surface and is often used to describe the quality of the surface. Surface roughness is also a key parameter of surface treatment and machining, which can optimize surface properties.

1.Use a surface roughness meter

Surface roughness meter is an instrument for measuring surface quality. Ra, Rz, Rq and other parameters of the surface can be measured, which uses the tip of a needle or drill to measure the surface unevenness, and then converts the measurement result into a digital reading. The data measured by this method is very accurate and scientific production plans can be made.

2.Use stylus surface meter

Stylus surfaceters use a mobile probe to touch the surface and a combination probe to record the rise and fall of the surface. This method measures the vertical height difference of the surface and produces a relative surface roughness reading. Compared with surface roughness meter, this method is more economical.

3.Use a light microscope

Examining a surface with an optical microscope can help determine its morphological characteristics and surface smoothness. When the surface roughness is high, details and defects can be seen more easily. This method helps to examine the surface and determine if there is a problem.

4.Use an electron scanning microscope

Scanning electron microscopy (SEM) provides you with a particularly accurate picture of the height lines that you can see on the surface. These height lines can characterize the roughness of the surface. This method is usually more expensive than light microscopy, but it can provide more accurate measurements.

How to choose the surface roughness measuring equipment

The method of measuring surface roughness has been known from the above content; Different production and experimental environments require different surface roughness measuring equipment, so how to choose the surface roughness measuring equipment? Here is a comparison of some measuring devices:

Comparison Table of Advantages and Disadvantages of Surface Roughness Meter

| Advantage | Disadvantages |

|---|---|

| Can be used for objects of various shapes and sizes | Expensive |

| High precision and efficiency | Regular calibration and maintenance required |

| Measurement results can be stored and shared |

Comparison Table of Advantages and Disadvantages of Stylus Surface Gauge

| Advantage | Disadvantages |

|---|---|

| Reusable | Limited measurement range |

| Cheap | The measurement results are influenced by the size and shape of the object |

| Portable |

Comparison Table of Advantages and Disadvantages of Optical Microscopes

| Advantage | Disadvantages |

|---|---|

| High precision and resolution | Limited measurement range |

| High observability | Affected by object shape and surface reflected light |

| Diversified functions |

Comparison Table of Advantages and Disadvantages of Electronic Scanning Microscope

| Advantage | Disadvantages |

|---|---|

| High precision and resolution | Expensive |

| Can be used for objects of various shapes and sizes | High requirements for operational skills and training |

| Detailed recording of geometric and topological features of objects | Maintenance and regular calibration required |

Surface roughness standard

The surface roughness standard table usually includes a series of numbers representing different surface roughness levels. For example, common surface roughness standards include Ra, Rz, Rp, Rv and other standards, which are used to describe the roughness of the surface, peak and valley height and other parameters.

The following are some common surface roughness standard parameters and their definitions:

Ra (Average roughness)

The average deviation between the surface profile and the reference line. The lower the Ra value, the smoother the surface. The unit is micron (μm) or inch (in).

Rz (mean peak-valley height)

The mean vertical distance between the highest peak and lowest trough on a surface. The larger the Rz value is, the larger the peak valley height difference is. The unit is micron (μm) or inch (in).

Rq (root mean square roughness)

The root mean square value of the height deviation of the surface profile, indicating the overall roughness of the surface. The lower the Rq value, the smoother the surface. The unit is micron (μm) or inch (in).

Rt (maximum peak-valley height)

The maximum vertical distance between the highest peak and lowest trough on a surface. The Rt value reflects the maximum unevenness of the surface. The unit is micron (μm) or inch (in).

Rpm (maximum peak height)

The highest peak height on a surface. Rpm values reflect the highest bumps on the surface. The unit is micron (μm) or inch (in).

Sa (Mean height)

The mean height value between the surface contour and the reference line. The higher the Sa value, the greater the surface fluctuation. The unit is micron (μm) or inch (in).

Sz (maximum height)

The maximum height deviation of the surface profile. The Sz value reflects the largest bulge or depression on the surface. The unit is micron (μm) or inch (in).

Common standards for surface roughness include ISO 4287 (Terms and definitions of surface roughness parameters), ISO 25178 (Methods and parameters for measuring surface roughness), ASTM E882 (Methods for measuring surface roughness), etc. These standards provide detailed measurement methods, parameter definitions and data analysis methods, which can be used as a basis for selection and comparison of surface roughness.

ISO 4287: Terms and definitions of surface roughness parameters

It contains definitions and terms of commonly used surface roughness parameters, such as Ra, Rz, Rq, etc.

ISO 25178, methods and parameters for measuring surface roughness

A variety of standards for surface roughness parameters and measurement methods are provided, including Sa, Sp, Sv, Sz, etc.

ASTM E882: Method of Measuring Surface Roughness

It includes methods and standards for measuring surface roughness, including parameters such as Ra, Rz, Rt, etc.

JIS B 0601: Terms and Definitions for surface roughness measurement

Japanese industry standard, provides terms and definitions for surface roughness measurement.

ASME B46.1: Surface roughness measurement

Asme standard contains methods and standards for measuring surface roughness.

Different methods of surface roughness change

See the table below:

| Surface feature | Surface roughness (Ra) value | Examples of processing methods |

|---|---|---|

| Clearly visible knife marks | Ra100、Ra50、Ra25 | Rough turning, rough planing, rough milling, drilling |

| Slightly visible knife marks | Ra12.5、Ra6.3、Ra3.2 | Fine turning, fine planing, fine milling, rough hinge, rough grinding |

| No visible machining marks, micro identification of machining direction | Ra1.6、Ra0.8、Ra0.4 | Fine turning, fine grinding, fine hinge, grinding |

| Dark glossy surface | Ra0.2、Ra0.1、Ra0.05 | Grinding, honing, superfinishing, polishing |

Comparison Table of Surface Roughness and Surface Finish Functions

There are corresponding comparison tables for surface finish and surface roughness. Roughness has a measurement formula, and the finish can only be compared with the template. So roughness is more scientifically rigorous than finish.

| Finish level | Roughness Ra (μm) | Surface Condition | Processing Method | Application Examples |

|---|---|---|---|---|

| ▽1 | 400~800 | |||

| ▽2 | 200~400 | obviously visible cut marks | rough car, boring, planing, drilling | surface after rough machining, 2 weld before welding, rough drilling wall, etc. |

| ▽ 3 | 100~200 | Visible knife marks | Rough turning, planing, milling and drilling | Generally non-binding surface, such as end face of shaft, chamfer, side of gear and pulley, non-working surface of keyway, weight reduction hole surface |

| ▽4 | 50~100 | Visible processing marks | Turning, boring, planing, drilling, milling, filing, grinding, rough hinge, milling teeth | The matching surface of unimportant parts, such as the end face of the pillar, bracket, shell, bushing, shaft, cover, etc. The free surface of fasteners, the surface of fasteners through holes, the non-centering surface of internal and external splines, and the round surface of gear top ring not used as a measurement reference |

| ▽5 | 25~50 | Slight processing marks are seen | Turning, boring, planing, milling, scraping 1 ~ 2 points /cm^2, pulling, grinding, filing, rolling, milling teeth | The surface that is not connected with other parts, such as the end face of the box, shell, end cover and other parts. Fixed support surfaces that require centering and fitting characteristics, such as centering worksurfaces between shafts, keys, and keyways. The surface of the fastening thread is not important. Surfaces that require knurling or oxidation treatment |

| ▽6 | 12.5~25 | Processing marks cannot be seen clearly | Turning, boring, planing, milling, hinge, pulling, grinding, rolling, scraping 1 ~ 2 points /cm^2 milling teeth | Install the shell hole of G-class bearing with diameter over 80mm, the tooth surface of ordinary precision gear, the positioning pin hole, the surface of V-shaped belt wheel, the outer diameter of internal spline centering, and the surface of the fixed center shoulder of the bearing cover |

| ▽7 | 6.3~12.5 | The direction of processing marks can be distinguished | Turning, boring, drawing, grinding, vertical milling, scraping 3 ~ 10 points /cm^2, rolling | It is required to ensure the surface of centering and fitting characteristics, such as the surface of taper pin and cylindrical pin, the axle diameter and shell hole matched with G-class precision rolling bearings, the axle diameter of medium-speed rotating bearings, the axle diameter and shell hole matched with E and D class rolling bearings with a diameter of more than 80mm, the inner and outer spline centering inner diameter, the outer spline key side and centering outer diameter, the interference fitting IT7 class hole (H7), Clearance with IT8 ~ IT9 grade holes (H8, H9), grinding gear surface, etc |

| ▽8 | 3.2~6.3 | Identify the direction of processing marks | Hinge, grinding, boring, drawing, scraping 3 ~ 10 points /cm^2, rolling | It is required to maintain long-term stable mating surfaces, IT7 grade shaft and hole mating surfaces, gear surfaces with high precision, important parts subjected to variable stress, and E and D grade bearings with diameter less than 80mm, shaft surfaces in contact with rubber seals, Measuring surfaces of gauges for holes and shafts, class IT13 to IT16, sizes greater than 120mm |

| ▽9 | 1.6~3.2 | The direction of processing marks cannot be identified | Cloth wheel grinding, grinding, grinding, super processing | Surface of important parts subjected to variable stress when working. Ensure the fatigue strength, corrosion resistance and durability of the parts, and do not destroy the surface of the nature of the working, such as the axle diameter surface, the surface required to be airtight and supporting surface, cone centering surface, etc. IT5, IT6 matching surface, surface of high precision gear, surface of axle diameter matching with G-class rolling bearing, IT7 ~ IT9 grade holes with size greater than 315mm and IT10 ~ IT12 grade holes and measuring surface of shaft gauge with size greater than 120 ~ 315mm |

| ▽10 | 0.8~1.6 | Dark glossy surface | Super processing | The surface of important parts subjected to greater variable stress during work. A cone surface that ensures accurate centering. A hole surface for hydraulic transmission. The inner surface of the cylinder liner, the outer surface of the piston pin, the guide surface of the instrument, the working face of the valve. IT10 ~ IT12 grade holes and shafts with gauges less than 120mm |

Industry application principles

The surface roughness has a great influence on the use of parts. Generally speaking, the surface roughness value is small, will improve the fit quality, reduce wear, prolong the service life of parts, but the processing cost of parts will increase. Therefore, the surface roughness value should be selected correctly and reasonably. When designing parts, the choice of surface roughness value is determined by the role of parts in the machine.

The general principle is to choose a larger surface roughness value under the premise of ensuring that the technical requirements are met. When making specific choices, you can refer to the following principles:

(1) The roughness value of working surface is smaller than that of non-working surface.

(2) The roughness value of the friction surface is smaller than that of the non-friction surface. The higher the friction velocity of the friction surface, the greater the unit pressure, the higher it should be; The roughness value of rolling friction surface is smaller than that of sliding friction surface.

(3) For clearance fitting, the smaller the clearance is, the smaller the roughness value should be; For interference fit, in order to ensure the strong and reliable connection strength, the larger the load, the smaller the roughness value is required. Generally, the roughness value of clearance mix ratio interference fit is smaller.

(4) The roughness of the matching surface should be equal to its dimensional accuracy requirements. When the fit properties are the same, the smaller the part size, the smaller the roughness value; For the same precision class, the roughness value of small size is smaller than that of large size, and the roughness value of shaft is smaller than that of hole (especially the accuracy of IT8 ~ IT5).

(5) The roughness value of the surface subject to periodic load and the inner fillet and groove where stress concentration may occur should be small.

Longsheng Technology: Your preferred partner for surface finishing projects

At Longsheng Technology, we have a professional team with years of experience that can provide customers with the most suitable solutions. In order to ensure the quality of our products, we strictly adhere to the ISO 9001:2015 quality management system and the ISO 14001 environmental management system, which can meet the surface finishing needs of different materials and requirements.

The surface finishing we provide includes but is not limited to polishing, spraying, chrome plating, electroplating, anodizing, etc.

If you need surface finishing services, please contact Longsheng Technology. We look forward to working with you to provide the best protection and appearance effect for your products

conclusion

In the study of friction, surface roughness is an important parameter that can significantly affect friction characteristics. To improve surface smoothness, methods such as grinding, surface polishing, laser refinement, or modification of surface chemical properties can be used. These methods can effectively reduce surface roughness and defects, improve surface morphology and quality, and thus improve the friction characteristics of solid surfaces.

Thank you for reading this article. Please feel free to contact us for more information.

Wishing you a happy life and smooth work!

Author: Longsheng Technology

FAQ

The control of surface roughness is realized by a series of fine machining processes. The surface roughness is usually controlled by the following methods:

Cutting: By reducing the cutting edge feed, reducing the cutting speed, choosing the appropriate workpiece and tool, etc., to achieve the control of surface roughness.

Grinding process: By selecting the appropriate grinding wheel, releasing the grinding wheel, adjusting the cycle of the grinding wheel, etc., the surface roughness can be controlled.

In practice, choosing the appropriate surface roughness usually requires reference to the specific requirements of the product. For example, where a large coefficient of surface friction is required, the surface roughness can be increased appropriately. And where the surface is smooth and not easily damaged, the surface roughness should be reduced accordingly. Therefore, in the selection of surface roughness, we need to understand the specific needs of the product, and control the surface roughness through gradual improvement.