Brass CNC Machining Services

Reliable on demand brass cnc machining services, we are committed to helping you achieve your manufacturing goals, get an instant CNC quote today and order your high quality custom brass parts at competitive prices

- Instant CNC brass parts online quotes

- Tolerances down to ±0.005mm

- Delivery in as little as 3 days

- All uploads are secure and confidential

Brass CNC Machining Services for Custom parts

If you need brass parts, then you need Longsheng’s brass CNC machining services. We have the most advanced online CNC machining center and experienced technical personnel. No matter what type of brass parts you need, we can provide high-quality brass machining services according to your needs.

Our brass CNC machining services include various types of parts, including electronic components, aviation, automotive, medical, and so on. Our expert team has provided brass parts to customers in various industries

From individual customers to large enterprises, Longsheng’s technical team can provide customers with the whole process of brass CNC machining services, including CAD drawing, sample production, batch production and other links. Our service team always maintains good communication and feedback to ensure that customers’ needs are fully understood and met.

Our Brass Parts Manufacturing Capabilities

Our brass CNC machining services include milling, turning and other processes, from rapid prototype design to customized production and operation, to meet the different processing needs of customers. With high-quality 4-axis and full 5-axis CNC machines, you can obtain high-precision and high-quality CNC brass parts

CNC Milling

Our CNC milling machine can meet the processing needs of brass parts of different shapes and sizes, such as metal shells, machined components, or difficult to machine areas. Whether you need individual components or mass production, we can quickly meet your needs.

CNC Turning

Our CNC lathe can handle various specifications of CNC parts, such as brass shafts, rivets, and precision cylindrical parts. We can also provide customized services according to customer needs to achieve the production of various brass parts and quickly complete batch machining.

CNC machining of brass materials

Longsheng supplies most of the industry standard materials. If you do not find the materials you want in the list, please contact us

| Materials | Content | Ultimate Tensile Strength (MPa) | Hardness (HB) | characteristic |

|---|---|---|---|---|

| Brass C21000 |

Copper (Cu): min 94.5% Zinc (Zn): max 5.5% |

275-345 | 65-85 | Good plasticity, corrosion resistance, and wide range of applications |

| Brass C22000 |

Copper (Cu): min 90.0% Zinc (Zn): max 10% |

310-380 | 70-90 | High strength, good corrosion resistance, suitable for wear resistance and sealing applications |

| Brass C26000 |

Copper (Cu): min 68.5% Zinc (Zn): max 31.5% |

310-410 | 65-85 | Low density, good wear resistance, suitable for contact with conductive components and decorative purposes |

| Brass C28000 |

Copper (Cu): min 59.0% Zinc (Zn): max 41% |

345-450 | 70-90 | High strength, good corrosion resistance and wear resistance, suitable for industrial and construction applications |

| Brass C31400 |

Copper (Cu): min 85.0% Zinc (Zn): max 15% |

310-400 | 70-90 | Good corrosion resistance, suitable for applications such as seawater environment and food processing |

| Brass C36000 |

Copper (Cu): min 60.0% Zinc (Zn): max 63.5% |

400-540 | 90-130 | Excellent processing performance, suitable for manufacturing complex shaped parts and automated processing |

| Brass C44300 |

Copper (Cu): min 70.0% Zinc (Zn): max 30% |

280-380 | 60-90 | High strength, good corrosion resistance, suitable for marine and chemical industrial environments |

| Brass C46400 |

Copper (Cu): min 58.0% Zinc (Zn): max 39% |

440-540 | 110-150 | Good corrosion resistance, suitable for valves, pump bodies, and seawater treatment equipment |

| Brass C51900 |

Copper (Cu): min 62.0% Zinc (Zn): max 67% |

450-540 | 100-150 | High strength, good corrosion resistance, suitable for applications such as bearings, gears, and springs |

| Brass C68700 |

Copper (Cu): min 76.0% Zinc (Zn): max 22% |

345-415 | 70-80 | Good corrosion resistance and excellent thermal conductivity, suitable for heat exchangers and condensers |

Why use our brass machining services

At Longsheng Technology, we are committed to helping you achieve rapid prototyping and production parts manufacturing goals, using our advanced processing technology and comprehensive production equipment to ensure that you obtain high-precision prototypes and high-quality production parts.

No minimum order quantity

There is no minimum order quantity, whether you need a single brass part or thousands of brass parts, we are happy to work with you and support custom machining of various shapes of brass parts, providing a variety of requirements such as accuracy, size, surface quality, material and geometry

Precise and tight tolerances

We manufacture brass parts for the aerospace, automotive and medical, providing full size and material inspection reports according to your requirements. With strong CNC machining capabilities and technical implementation, strict tolerances and the best accuracy of ±0.005mm can be guaranteed.

Competitive pricing

Whether your brass cnc machining project is mass production or small batch customization, we can provide you with the perfect solution at a competitive price as an important service commitment to ensure that our customers receive the best quality service and the best value products.

Brass CNC machining Application

- Mechanical gears

- Various types of nuts (fasteners)

- Clock hands

- Automotive terminals

- Threaded sections of mechanical screws

- Plumbing components

- Outer rings for mechanical bearings

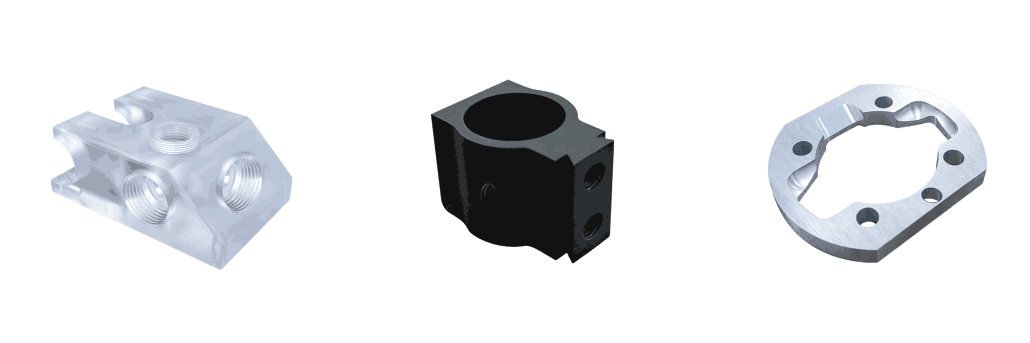

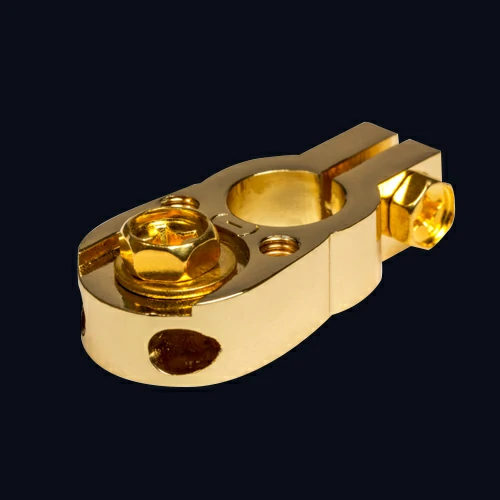

CNC Machining Brass Parts Picture

View the custom brass parts we process for customers, from rapid prototyping, small batch production to batch production orders

Frequently Asked Questions about brass Parts Manufacturing

We provide new product developers with engine machining parts suitable for functional testing or final use of engineering -level materials. Get your required percision CNC machining services support by reading FAQ.

Brass material selection depends on the specific processing requirements and application requirements. Other brass materials such as brass C28000, brass C46400, etc., may also be suitable for specific CNC machining applications. It is recommended to have a detailed discussion with the processing experts of Longsheng Technology when selecting brass materials to determine the best brass material choice.

We do not have a minimum order quantity. Whether you need a single brass parts or thousands of brass parts, we are happy to work with you.

Yes, we have a team of experienced engineers who can assist you with design and prototyping. We can work with you to optimize your designs for manufacturability and efficiency.

The price of brass cnc machining is affected by many factors, such as the number of processing, part size, processing difficulty and so on. Compared with traditional manual processing, the price of cnc machining will be more affordable and the processing efficiency is higher. If you want to know the specific price, please send the specific processing requirements to Longsheng technology technicians, we will return the quotation within a day

Put your parts into production today

- All information and uploads are secure and confidential.

Latest Blog Posts