Brass is a very high quality metal, with a variety of characteristics, such as high corrosion resistance, good taste, good electrical conductivity, easy processing and so on. Therefore, brass products have been widely used in home, art, construction, automotive and other industries. If you want to know how to process brass, this guide will give you the best answer.

Basic Overview of Brass

Brass is an alloy of copper and zinc, with a general copper content of over 60% and zinc content of below 40%. It is named after its golden appearance. Brass has good plasticity and processability, and is commonly used in the manufacturing of metal tools, musical instruments, decorations, construction supplies, electronic components, bicycle mudguards, etc. However, due to the soft softening of brass materials, special treatment is usually required to achieve specific dimensions, shapes, and surface quality.

Physical properties of Machine brass materials

Brass is a common alloy composed of copper and zinc. Here are some common brass grades, their physical properties, and a simple table to display this information:

| Grade | Copper Content | Zinc Content | Lead Content | Phosphorus Content | Density (g/cm³) | Melting Point (°C) | Tensile Strength (MPa) | Elongation (%) | Brinell Hardness |

|---|---|---|---|---|---|---|---|---|---|

| C26000 | 70% | 30% | N/A | N/A | 8.53 | 899-940 | 310 | 40 | 90 |

| C28000 | 60% | 40% | N/A | N/A | 8.79 | 900-940 | 360 | 30 | 100 |

| C36000 | 61% | 35% | 3% | N/A | 8.73 | 900-940 | 370 | 25 | 100 |

| C44300 | 70% | 30% | N/A | N/A | 8.8 | 890-930 | 400 | 20 | 110 |

| C46400 | 63% | 37% | N/A | N/A | 8.85 | 900-940 | 450 | 20 | 120 |

| C52100 | 88.6% | 10% | N/A | 1.4% | 8.9 | 900-940 | 400 | 30 | 110 |

Basic steps of brass machining

The basic steps of brass machining are as follows:

1.Design and measurement

Before processing brass, you need to design the product to be processed, and you need to make accurate measurements and planning. Because brass is a very soft and deformable material, if the size error occurs during the production process, the quality of the final product will be greatly affected.

2.Cutting and grinding

Next, you need to use various machines to cut and sand the brass surface. During the cutting process, you can use a drill and saw blade to separate out the desired shape. For smaller materials a shear is needed. Then, you need to use sandpaper or a polisher to smooth the cutting surface.

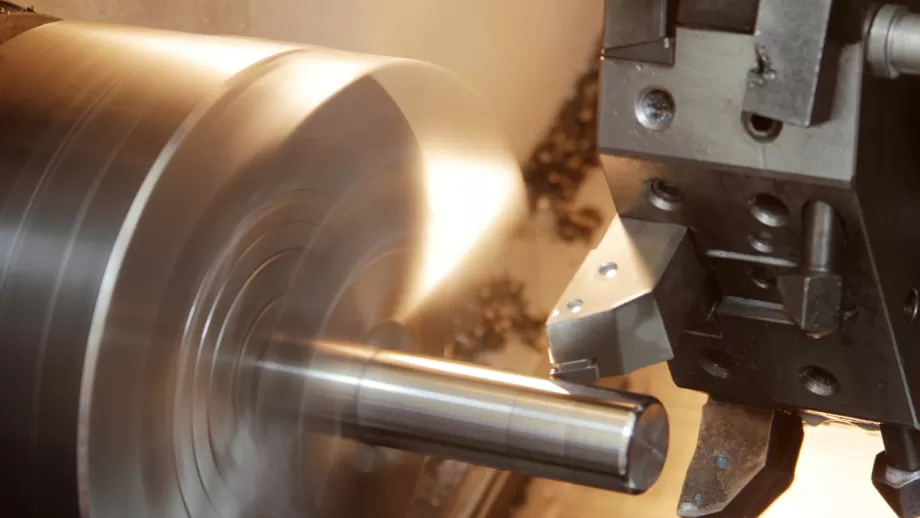

3.Drilling and lathe machining

When you need to drill holes in brass surfaces or construct more complex structures, you need to use drill presses and lathes. When you drill with a drill press, you can use a deep drill bit and a variety of large and small bore bits. In order to achieve the fine surface quality requirements of brass products, it is necessary to use specific equipment such as wheel lathes, rolling lathes and CNC lathes.

4.Heat treatment and oxidation treatment

After cutting, grinding, drilling, and lathe machining, the brass needs to be heat treated or oxidized. Heat treatment can improve the hardness and corrosion resistance of brass, thereby enhancing its compression resistance, toughness and toughness. Oxidation treatment can increase the surface texture and beauty of brass.

| Surface Treatment Option | Texture | Applications | Characteristics |

|---|---|---|---|

| Polishing/Grinding | Smooth, high reflectivity | Furniture, hardware accessories, decorative items | Provides a smooth and shiny brass surface |

| Gold Plating | Smooth, metallic texture | Jewelry, decorative items, hardware accessories | Provides a gold-colored appearance, increases corrosion resistance |

| Anti-oxidation Coating | Smooth, good oxidation resistance | Components, electronic devices, hardware products | Protects the brass surface from oxidation, extends lifespan |

| Spray Coating | Smooth, uniform coating | Furniture, decorative items, art pieces | Offers a variety of colors, protects the brass surface |

| Acid Etching | Textured, rough surface | Jewelry, art pieces, signage | Creates textures and patterns, adds artistic touch to the brass surface |

| Oxidation | Natural oxidation layer, unique texture | Jewelry, art pieces, interior design | Develops a natural oxidation layer, creates a unique texture and appearance |

| Paint Coating | Smooth, wide color range | Furniture, decorative items, hardware products | Provides a wide range of color options, offers durability to the brass surface |

| Anti-fingerprint Coating | Smooth, anti-fingerprint | Door handles, touch panels, hardware accessories | Reduces visibility of fingerprints and smudges, easy to clean |

conclusion

Brass is one of the important materials in the manufacture of various parts and equipment. With the right tools and methods, you can easily process brass materials to the desired shape, size and finish,We provide a one-stop service from design to rapid prototyping production, ensuring that customers can achieve the most satisfactory machining results. If you have brass online CNC machining needs, then we will be your most ideal choice.

Our brass CNC machining services

Whether you need small batch machining or large volume production, we can provide you with a tailored machining solution. We have a deep understanding of customer needs and provide the most suitable machining technology and equipment to ensure the perfect balance of product quality and efficiency.

Mobile:+86 185 6675 9667(Gloria Wu)

E-Mail:gloria.wu@longshengmfg.com