Medical CNC Machining

Reliable CNC machining services provide medical equipment prototyping and production. From simple to complex medical parts, we can help you achieve your goals through rapid prototyping, mass and small-scale production.

- Manufacturing on demand

- ISO 9001:2015 certified

- High precision medical products

- All uploads are secure and confidential

CNC Machining for Medical Industry Manufacturers

Utilize top-level solutions for medical product development. Longsheng Technology provides professional design and manufacturing of customized medical parts. With the combination of advanced technology and excellent manufacturing expertise, we provide solutions at all stages, enabling us to turn your medical products into reality in the most effective way possible

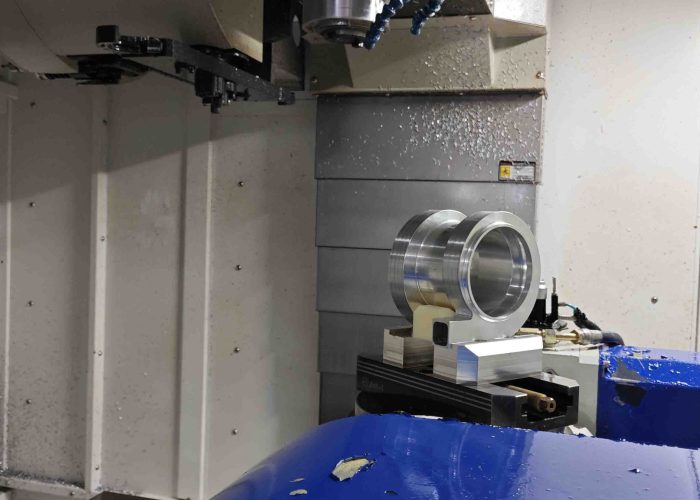

We have the most advanced CNC machine tools and technical equipment, equipped with multi axis control and automation functions to achieve highly accurate part machining, which can process medical parts of various shapes, specifications, and materials. Whether it’s small batch orders or large-scale production, we are able to respond quickly and ensure delivery deadlines.

We provide customized solutions to meet your specific requirements. Whether it’s a full process solution from design to production, or part machining for specific projects, our team will work closely with you to ensure the best results.

By choosing us, you will receive high-quality medical parts machining services, thereby enhancing your product quality and market competitiveness

Our Manufacturing Capabilities

Whether it is small-scale or large-scale production, we have the ability and experience to provide you with high-quality medical parts. Through our manufacturing capabilities, you can obtain reliable, accurate, and industry standard medical parts, laying a solid foundation for the quality and success of your products.

CNC Milling

Our CNC milling machine is capable of handling various shapes and complexity of parts processing requirements, including flat parts, curved parts, hole processing, and so on. Whether it is small or large parts, we can customize machining according to your requirements.

CNC Turning

Our CNC lathe machine can process various medical grade materials' parts, including cylindrical parts, thread machining, internal and external grinding, etc. We have corresponding processing capabilities for both small and large diameter parts.

Advanced CNC machines

We have advanced CNC lathes and CNC milling machines that can perform efficient and accurate machining. Our equipment has multi axis control and automation functions, enabling highly accurate part manufacturing.

Medical CNC Machining material

Longsheng supplies most of the industry standard materials. If you do not find the materials you want in the list, please contact us

| Aluminum alloy material | Stainless Steel | Alloy Steel | Copper alloy | Other alloy | plastic | Special materials and other |

|---|---|---|---|---|---|---|

| Aluminum alloy 6061 | Stainless steel 303 | Q235 (A3 steel) | Bronze-H59 | Electrician pure iron-DT4C | Engineering Plastic -ABS | Carbon fiber board |

| Aluminum alloy 5052 | Stainless steel 304 | 45 steel | Bronze-H62 | Electrician pure iron-DT4E | Polytetrafluoroethylene-PTFE | graphite |

| Aluminum alloy 2A12 | Stainless steel 316 | Cr12 | Copper-T2 | Titanium alloy-TC4 | Saigang-POM | - |

| Aluminum alloy 7075 | Stainless Steel 316L | 3Cr13 | Oxygen Tu2 | Magnesium alloy -AZ91D | Organic Glass-PMMA | - |

| - | Stainless steel 420 | Spring Steel-65MN | Tin Bronze-QSN-6-6-3 | - | Polyzenzene-PPS | - |

| - | Stainless Steel-17-4PH | Mold Steel-SKD11 | Beryllium copper-C17200 | - | Nylon-PA6 | - |

application for Medical CNC machining

The following are just some examples of medical CNC machining applications. Our medical CNC machining can meet the needs of the medical industry for high-precision, high-quality, and complex shaped parts, and provide critical support for medical equipment and treatment.

- Surgical blades

- Clamps

- Forceps

- Artificial shoulder joints

- Artificial knee joints

- Artificial hip joints

- Ventilator components

- Monitor parts

- Scanner components

- X-ray machine components

- Syringes

- Scissors

- Robotic arm components

- Electronic instrument panels

- Handheld device casings

- Monitor casings

- Artificial aortic valves

- Artificial mitral valves

- Dental crowns

- Restorations

- Dental implant bases

- Interlocking nails

- Bone plates

- Bone screws

Surface finishing options for medical parts

The following finishing and post-processing options can be customized according to specific medical part requirements to meet the appearance, performance, and hygiene requirements of the medical industry.

- Sandblasting

- Electroplating

- Hard Anodizing (HAO)

- Polishing

- Surface coating

- Spray coating or painting

- Cleaning and sterilization treatment

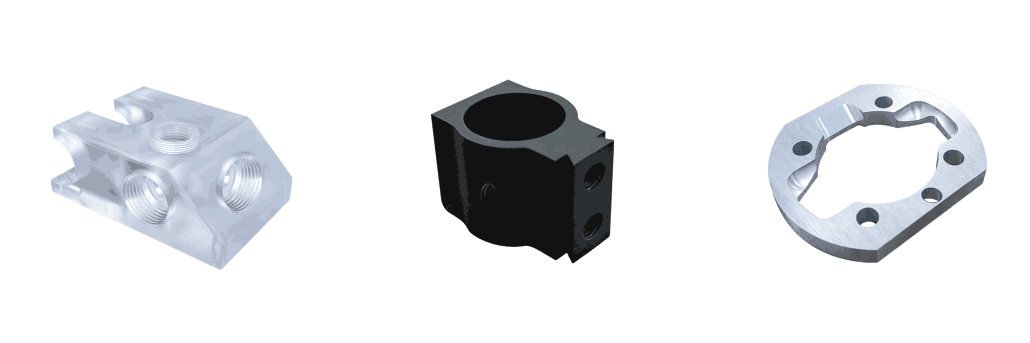

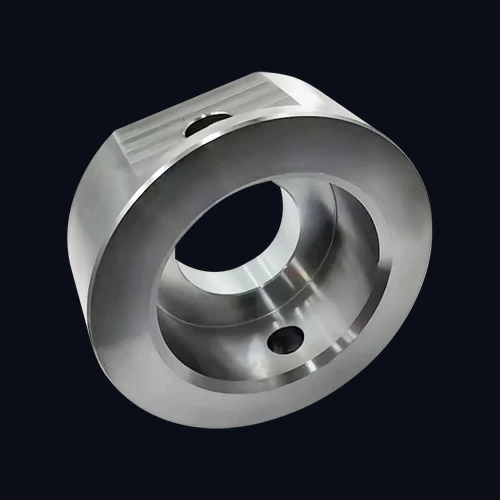

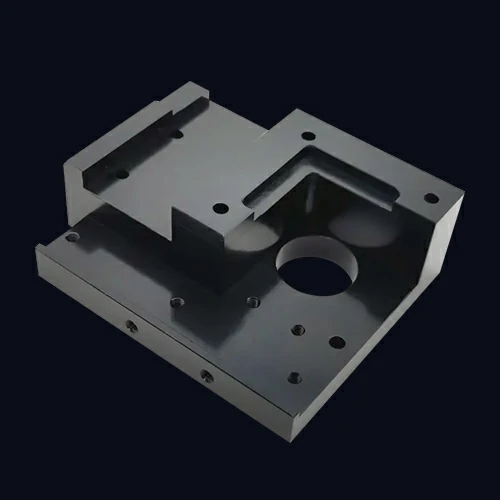

Medical CNC Machining Parts Picture

View the custom medical parts we process for customers, from rapid prototyping, small batch production to batch production orders

Medical Parts Manufacturing FAQ

We provide new product developers with engine processing parts suitable for functional testing or final use of engineering -level materials. Get your required precision CNC machining services support by reading FAQ.

Yes, we promise to keep the client's design and project information confidential. We have established strict confidentiality protection measures within the organization to ensure that customers' intellectual property and trade secrets are protected.

We have the ability to process various types of medical parts, including implant parts, surgical tools, medical equipment components, etc. Whether it's complex curved parts or precision hole machining, we can meet your needs.

Yes, we are a manufacturer specializing in CNC machining in the medical field. We have accumulated years of experience in the medical industry and have collaborated with numerous medical equipment manufacturers to provide high-quality medical parts machining services

We have strong production capacity and flexible production plans, which can meet production needs of different scales. Whether it is small-scale or large-scale production, we can deliver on time and ensure the quality and accuracy of medical parts.

Yes, we are committed to providing customized solutions to meet the specific needs of our customers. We can provide personalized parts processing and production services based on your design and requirements, ensuring the best results.

Yes, we can provide sample machining services according to customer needs. You can provide us with sample designs or requirements, and we will make samples for you and provide corresponding machining reports

The delivery cycle depends on the specific requirements of the order, including part complexity, machining quantity, and special machining techniques required. We will do our best to ensure the accuracy and timeliness of the delivery deadline, and communicate with customers to meet the project schedule and requirements.

Yes, we can provide medical component design support. Our engineering team has rich experience and professional knowledge, and can collaborate with customers to provide design suggestions and optimizations to ensure the manufacturability and optimal performance of medical parts.