CNC machining of aluminum has high production efficiency. Compared to traditional manual machining , CNC machining of aluminum can complete more machining tasks in a shorter time. CNC machining aluminum is a very ideal choice for products that require mass production.

Although CNC machining of aluminum has many advantages, companies may also seek alternatives to aluminum for CNC machining. After all, it is usually more expensive than alternatives such as steel, and partly due to the high energy costs of aluminum production.

This article will explore the advantages of CNC machining aluminum and the characteristics of some alternative materials to help you understand and choose the most suitable material for your needs.

Advantages of CNC machining aluminum

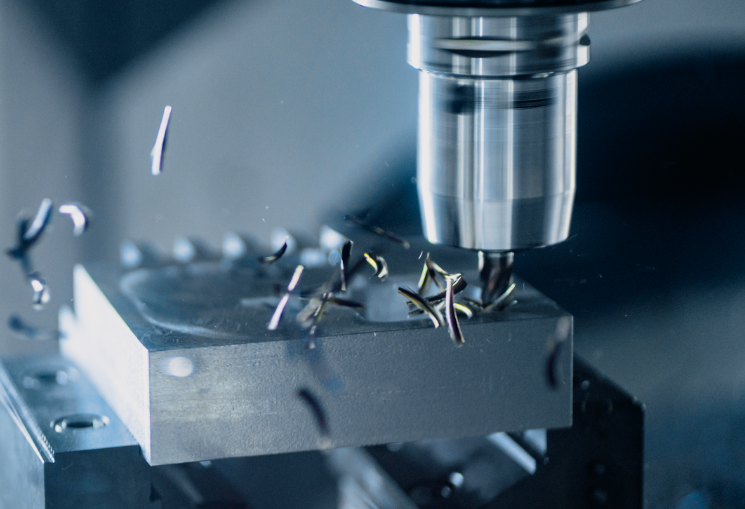

CNC machining of aluminum is the use of computer numerical control machine tools to process aluminum into various shapes and sizes. The following are the main advantages of CNC machining aluminum:

1.Lightweight design

Compared to many other metal materials, aluminum alloys have a lower density. This enables the use of CNC machining of aluminum alloy components to achieve lightweight design, thereby reducing overall weight. For industries such as automobiles, aerospace, and electronic equipment, lightweight design is an important means of reducing energy consumption and improving efficiency.

2.Good machining performance

Aluminum alloy has good plasticity and machining performance, whether it is cutting, milling, drilling or thread machining , aluminum alloy can easily handle. Therefore, using CNC machining can achieve efficient and accurate production of aluminum parts.

3.Good surface quality

CNC machining of aluminum can achieve excellent surface quality during the machining process. Due to the high precision of tools and mechanical equipment, precision CNC machining of aluminum can achieve smooth and flawless surface treatment, providing high-quality finished products.

Table of Cutting Parameters for CNC Aluminum Standard Tools

In the process of CNC machining aluminum, different cutting tools and tool materials have different machining effects on different workpieces. The following is a reference table for cutting parameters of different tools for cutting aluminum materials, which can help you obtain some reference opinions during the tool selection process.

1.Milling Tools:

| Tool Type | Specification | Size | Cutting Speed (m/min) | Feed Speed (mm/min) | Cutting Depth (mm/tooth) | Cutting Width (mm) |

|---|---|---|---|---|---|---|

| Solid Carbide End Mill | 2 Flutes, Straight Shank | Φ6×Φ6×50×100 | 200-400 | 800-1500 | 0.05-0.15 | 1-3 |

| PCD/PCBN End Mill | 4 Flutes, Straight Shank | Φ8×Φ8×60×120 | 300-600 | 1000-2000 | 0.05-0.25 | 1-5 |

| High-Speed Steel End Mill | 2 Flutes, Straight Shank | Φ10×Φ10×75×150 | 60-150 | 200-500 | 0.05-0.2 | 1-3 |

2.Drilling Tools:

| Tool Type | Specification | Size | Cutting Speed (m/min) | Feed Speed (mm/rev) | Cutting Depth (mm) |

|---|---|---|---|---|---|

| Solid Carbide Drill | Φ4×Φ6×50×100 | Φ4×Φ6×50×100 | 60-200 | 0.05-0.25 | 1-5 |

| PCD/PCBN Drill | Φ6×Φ8×60×120 | Φ6×Φ8×60×120 | 100-400 | 0.05-0.3 | 1-8 |

| High-Speed Steel Drill | Φ8×Φ10×75×150 | Φ8×Φ10×75×150 | 30-80 | 0.03-0.15 | 1-3 |

3.Turning Tools:

| Tool Type | Specification | Size | Cutting Speed (m/min) | Feed Speed (mm/rev) | Cutting Depth (mm) |

|---|---|---|---|---|---|

| Solid Carbide Turning Tool | Φ16×16×100 | Φ16×16×100 | 100-250 | 0.1-0.5 | 1-5 |

| PCD/PCBN Turning Tool | Φ20×20×120 | Φ20×20×120 | 150-400 | 0.2-0.8 | 1-8 |

| High-Speed Steel Turning Tool | Φ25×25×150 | Φ25×25×150 | 30-80 | 0.05-0.3 | 1-5 |

We recommend using high-speed drills and milling cutters for aluminum cutting. High speed drill bits have good self-cleaning ability and high-precision machining effects, while milling cutters can more efficiently achieve larger cutting areas.

Alternative Materials for CNC machining Aluminum

Although CNC machining of aluminum has many advantages, sometimes other materials can also be considered as substitutes. The following are some common alternative materials:

metal

1.Steel and stainless steel

Steel and stainless steel are widely used materials in CNC machining. Due to its high strength, steel is often favored for high stress applications and applications that require secure welds. Steel can withstand very high temperatures, while stainless steel can undergo heat treatment to enhance its corrosion resistance.

However, although machining steel is designed to improve machinability, aluminum is still easier to machine than machining steel. Steel is also heavier and harder than aluminum, which are also considered, depending on the application.

If the key consideration is temperature resistance rather than weight, then steel may be an ideal substitute for aluminum.

2.titanium

Titanium can be used as a similar substitute for aluminum because its main advantage is its excellent strength to weight ratio – which is also one of the main advantages of aluminum. Titanium has a weight similar to aluminum, but its strength is almost twice that of aluminum. Like aluminum, it also has strong corrosion resistance.

These advantages are reflected in the higher price range of titanium. Although this material is an excellent choice for aircraft components and medical equipment, its cost may be prohibitive.

When lightweight is the primary consideration, and more importantly, when manufacturing budgets have a certain degree of flexibility, machining titanium is a suitable alternative to aluminum.

3.magnesium

Although lightweight metal magnesium is not the most common machining material, it has many advantages of common aluminum alloys. In fact, magnesium is one of the easiest metals to process, making the machining process fast and efficient.

What is a potential disadvantage for a mechanical workshop? Magnesium chips are extremely flammable and can further intensify when exposed to water, which means that mechanics must be cautious when removing debris. And the corrosion resistance of magnesium is not excellent enough.

4.Brass (copper zinc alloy)

Brass is a metal with a golden appearance, a highly machinable metal with high hardness and wear resistance, and its price is slightly higher than aluminum. It is commonly used in parts such as valves and nozzles, as well as structural components, and its high machinability makes it suitable for large-scale orders.

5.Pure copper

Copper and aluminum have multiple similar material properties. However, the excellent conductivity of copper makes it more suitable for various electrical applications. Although pure copper is difficult to process, many copper alloys have machining properties similar to popular aluminum grades.

Engineering thermoplastic

1.POM (Polyoxymethylene resin)

CNC machining projects do not need to be limited to metals. In fact, depending on the application, several engineering thermoplastics can match or surpass some of the advantages of aluminum.

Due to its excellent machining performance, aluminum is often favored, so a feasible plastic substitute is POM, which, like aluminum, is very suitable for machining processes. POM has a low melting point, but plastic strength is very high.

POM is an electrical insulator, which is suitable for electronic housing and other parts, and it is also suitable for Machine element. However, due to its completely different insulation performance from aluminum, it can only be used as a substitute for the same type when thermal conductivity and conductivity are negligible.

2.PTFE (Teflon)

Like POM, PTFE (Teflon) is a highly machinable thermoplastic that is an excellent electrical insulator with extremely low friction. However, unlike POM, PTFE is also resistant to high temperatures (up to 260 ° C), making it a viable alternative to aluminum in high-temperature applications.In addition, the high chemical resistance of PTFE (Teflon) makes it a commonly used component machining material in the food industry.

3.PEEK

Although PEEK is more difficult to process than the first two thermoplastic plastics, its high strength and thermal stability (resistance to temperatures up to 260 ° C) make it a true substitute for aluminum of the same kind. PEEK is widely used in fields such as aerospace, automobiles, medical devices, electronics, petrochemicals, and is widely popular in machining parts such as valves, bearings, pumps, and nozzles, demonstrating its ability to resemble metals.

One stumbling block is price. As a high-performance polymer, PEEK is a relatively expensive and processable thermoplastic, so it is only suitable for machining projects that cannot use common materials such as aluminum.

4.ABS

ABS is commonly used as an injection molding material and has also been used as 3D printing wire in recent years. Although ABS has little in common with aluminum, it is still a multifunctional lightweight material used for CNC machining, with higher than average impact strength.

5.Other

Most other processable plastics are very different from aluminum, including PC, ABS+PC, PP, PS, PMMA (acrylic acid), PAGF30, PCGF30, DHPE, HDPE, and PPS.

Alternative to specific aluminum grades

| Aluminum Grade | Application | Alternative Materials |

|---|---|---|

| 6061 | Aerospace, automotive parts, structural components, welding assemblies, etc. | Steel, titanium alloy, magnesium alloy |

| 7075 | Aerospace, aviation parts, high-strength applications, racing parts, etc. | Steel, titanium alloy, magnesium alloy |

| 5083 | Ships, marine platforms, pressure vessels, seawater desalination equipment, etc. | Stainless steel, nickel alloy, titanium alloy |

| 5052 | Aircraft, ships, automotive panels, household appliances, can bodies, etc. | Stainless steel, nickel alloy, copper |

| 2011 | Automatic lathe parts, electrical connectors, nuts, bolts, etc. | Brass, nickel alloy, steel |

conclusion

CNC machined aluminum is an ideal material for a wide range of applications due to its strength, corrosion resistance and plasticity. However, in some cases, steel or carbon fiber composites may be a better alternative. When choosing materials, we should make informed decisions based on specific needs and budgets.

FAQ

CNC machining aluminum has a series of advantages such as light weight, high strength, corrosion resistance, good thermal conductivity and excellent machining performance, which is suitable for the needs of various industries. It has obvious advantages in the manufacture of lightweight products, outdoor equipment and high temperature environments, and is an ideal choice.

CNC machining aluminum is made by cutting and shaping aluminum through machine tools. The cast aluminum is melted and poured into the mold to cool. Although casting aluminum can achieve complex geometry, CNC machining aluminum generally has greater precision and consistency.

Yes, CNC machining is widely used in automobile manufacturing. It can be used in frames, engine components, suspension systems, etc. The lightweight design and high strength of CNC machining make it ideal for automotive manufacturing.