Prototype CNC Machining is a state-of-the-art manufacturing technique used to make functional prototypes of products. It’s the use of CNC machinery to carve a product prototype out of a single block of material (like plastic or metal). Before mass production of a product begins, any flaws in the design can be identified and addressed.

Prototype CNC Machining can be cost-effective for low-volume production runs. This article will give us an in-depth introduction to Prototype CNC Machining, including its advantages and disadvantages, typical approaches, critical considerations, popular applications, and more.

What Exactly Does CNC Prototype Machining Entail?

It combines computer numerical control machining with rapid prototyping results in the term ” Prototype CNC Machining,” frequently used in the manufacturing industry. CNC machining refers to creating a physical product prototype using CNC equipment from a CAD or 3D model. A Prototype CNC Machine reads instructions from a digital file and then uses those instructions to move a cutting tool precisely. The result is a component that consistently performs as expected and never deviates from the specified parameters.

| Aspect | Description |

| Definition | CNC Prototype Machining refers to the process of using Computer Numerical Control (CNC) technology to produce functional prototypes or small batches of complex parts or components. It combines computer programming, automated machinery, and precise tooling to create accurate and detailed prototypes. |

| Workflow | The process begins with creating a 3D CAD model of the part or component to be manufactured. The CAD data is then converted into CNC machine-readable code (G-code). The CNC machine uses this code to control the movement of the cutting tools and machining processes. |

| Material Selection | CNC prototype machining can work with a variety of materials, including metals, plastics, wood, and composites. The choice of material depends on the desired characteristics and the intended functionality of the prototype. |

| Precision and Accuracy | CNC machines offer high precision and accuracy, enabling the production of intricate and complex geometries with tight tolerances. This level of precision ensures that the prototypes closely match the intended design. |

| Speed and Efficiency | Compared to traditional manual machining methods, CNC prototype machining is faster and more efficient. Once the CNC program is set up, the production process can be automated, reducing lead times and enhancing productivity. |

| Iterative Design | CNC prototyping allows for rapid iteration and design improvements. Design changes can be easily implemented in the CAD model, and the updated G-code can be fed into the CNC machine to create a new prototype quickly. |

| Cost-effectiveness | While CNC prototype machining may have higher upfront costs due to equipment and programming expenses, it becomes cost-effective for producing multiple prototypes or small batches of parts. The reduced need for manual labor also contributes to overall cost savings. |

| Applications | CNC prototype machining finds applications in various industries, including automotive, aerospace, electronics, medical devices, and consumer goods. It enables companies to test and validate designs before mass production, reducing the risk of costly errors and ensuring product quality. |

| Quality Control | Throughout the CNC machining process, quality control measures are essential to verify that each prototype meets the required specifications. This may involve inspections, metrology, and testing to ensure the prototypes’ accuracy and functionality. |

| Future Developments | Advancements in CNC technology, such as multi-axis machining, improved software, and better tooling materials, continue to enhance the capabilities of CNC prototype machining. This drives innovation and supports the development of more sophisticated prototypes. |

Companies often employ Prototype CNC Machining to make a few product samples before going into full-scale manufacturing. There are various uses for prototype machining, including testing the expected functioning and seeing how the final product would look.

The employment of specialized software and hardware in Prototype CNC Machining allows for increased management of the production process. When time and money are of the essence in creating a prototype of a problematic part, Prototype CNC Machining ing is the ideal option.

How Does Prototype Machining Work?

The machining process begins with a 3D computer-aided design (CAD) file of the prototype. From the CAD file, we generate CNC-readable G-code. Before starting machining, the G-code is verified for errors and other issues. We will commence manufacturing once we have finished testing the component and are happy with the results.

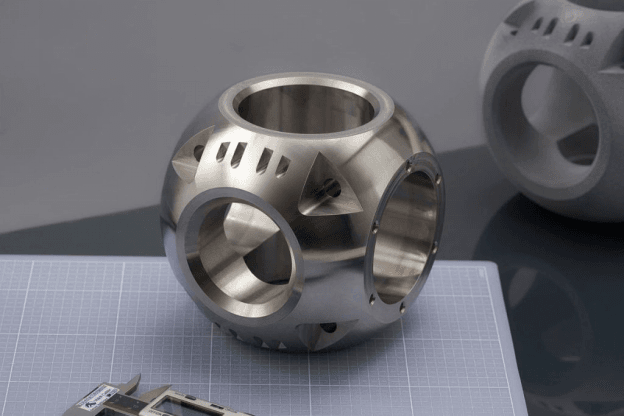

Subtractive manufacturing includes processes like Prototype CNC Machining. To machine the parts, the G-code controls a set of electric drills, saws, and other instruments. We can access a vast pool of raw materials to select during production. The finished part is removed from the machine and given the touches you specified.

Why Is CNC Machining Preferred for Prototyping?

CNC machining is an excellent prototype technique for several reasons. CNC technology provides precision and accuracy because it uses computerized controls to track the cutting tool and the motion of the workpiece. These digital controls consider every part of your design, ensuring the final prototype meets your specifications.

However, if Prototype CNC Machining is employed, production time and materials can be reduced. Unlike with processes like injection molding, the producer and the product developer don’t need to wait for the tolerances and molds to be available. CNC machining’s versatility makes it well-suited for prototyping complex or out-of-the-ordinary creations.

Which CNC Prototyping Methods Are Most Typically Employed?

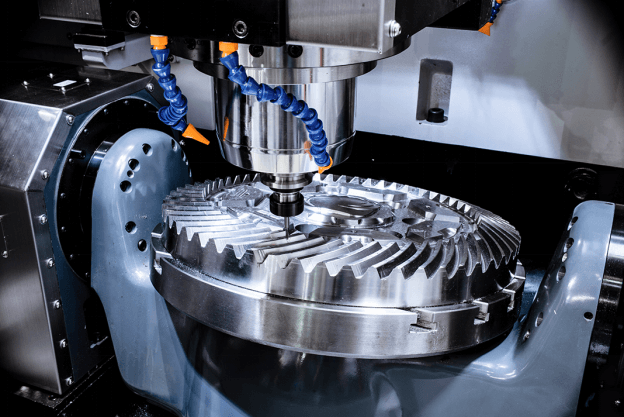

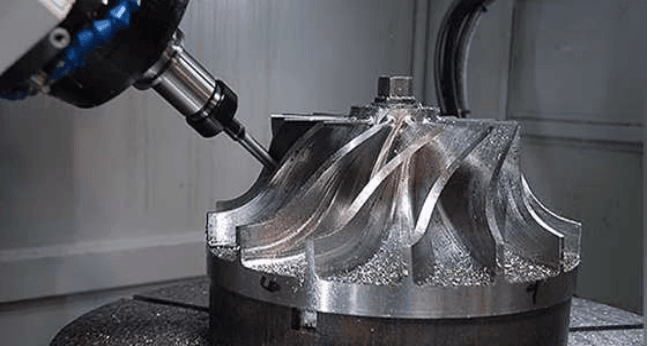

Prototype Subtractive machining, in which material is removed from a workpiece to produce a result, is used in several Prototype CNC Machining processes. Prototype CNC Machining is widely utilized in the manufacturing industry, and standard Prototype CNC Machining processes include milling, turning, grinding, and drilling.

Milling

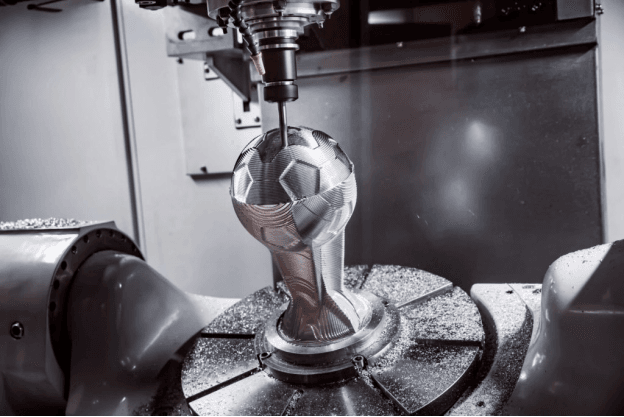

Machining via milling involves continuously spinning a cutting tool. The chips are scraped off as the milling cutter touches the workpiece. Milling operations such as chamfering, end milling, face milling, drilling, boring, tapping, etc., are all examples of CNC milling operations.

Milling is a flexible production method that may produce precise and accurate parts with tight tolerances. It may be used with many different materials and is fast. Milling’s strength lies in making a wide range of complex parts. Cons include the waste it creates, the number of tools you’ll require, and the high cost of any machinery you’ll use.

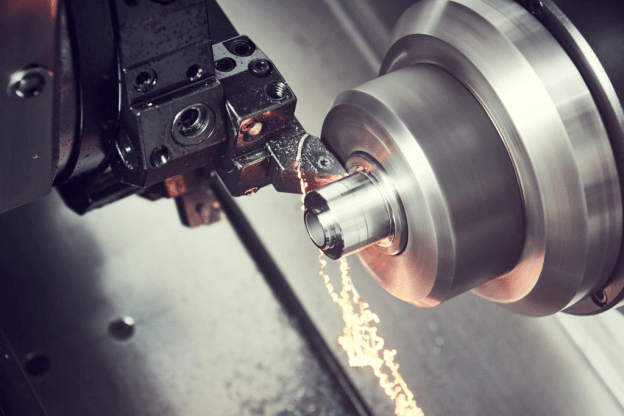

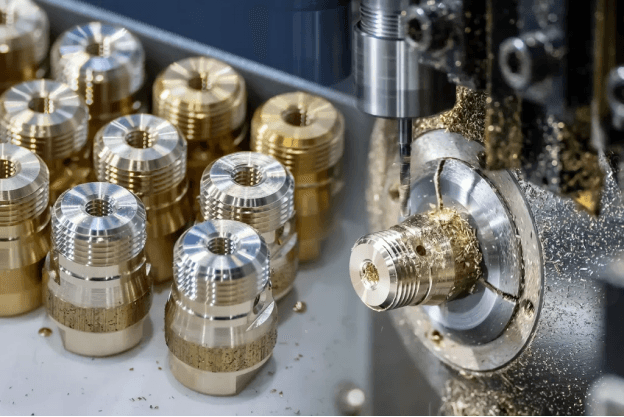

Turning

There is a world of difference between turning and milling. Turning is the polar opposite of milling. The workpiece spins, as opposed to the cutting tool rotating. Attached to the rotating workpiece, the device removes swarf or metal shavings.

CNC turning is commonly used to create shafts. It can be used on the outside or inside of a cylinder, giving you more options. Turning has the potential for high degrees of precision with the correct part.

Grinding

Materials that aren’t wanted can be ground away by a CNC grinding machine’s revolving grinding wheel. The goal is to give a mirror-like polish to a metal object.

An extremely high-quality finish is attainable. As a result, it is applied as a last process rather than during the manufacturing stage.

Drilling

While milling machines can drill holes, drills are much more efficient.

What is the main distinction between these two methods? Milling tools have many cutting edges around the head, while drills use the sharpened tip to bore a hole.

Since CNC drilling machines are more exact and economical, they are frequently used to automate this procedure.

The four distinct prototypes and their respective applications

Let’s talk about the many prototyping options available before diving into the inner workings of CNC machines.

1. Prototype in Visual Form

This is a static representation of the final product’s design and aesthetics. Clay, foam, or plastic are common materials for this. Designers and engineers can use these models to double-check the aesthetics and functionality of the final product.

2. Prototype Demonstration of Concept

Prototypes are created for the express purpose of determining whether or not a proposed design is workable. This prototype serves its purpose. However, it may want some finishing touches. It is used to see how well an idea works in practice and undergo rigorous testing. They’re constructed from everyday household items like cardboard, foam, or 3D-printed components.

3. Functional Model

A functional prototype of a product is a model that may be used to predict how the finished product will function. It examines a product’s efficiency, longevity, and dependability. Prototypes that work are typically fabricated from metal, plastic, or even wood.

4. Prototype for a Presentation

The prototype utilized for marketing or showing off to possible investors is far more polished and detailed if it is a presentation prototype. Metal, glass, or high-grade plastic are standard components of presentation prototypes.

5. CNC Machine Varieties

Mills, lathes, routers, and plasma cutters are just some of the computer numerical control machinery available. Machines come in all shapes and sizes, each serving a specific purpose. Mills can cut, drill, and shape metal, plastic, and other materials. In contrast to routers, which are used to carve complicated designs into sheet materials, lathes are generally used for turning cylinders. Metal is sliced precisely by a high-temperature plasma flame used by plasma cutters.

How Can Prototype CNC Machining Be Put to Use?

Prototypes produced using numerical control machines are employed in nearly every sector that requires such precision. Prototypes having the same functionality as the final product are often needed in these fields. Some industries that profit from Prototype CNC Machining are listed below.

Healthcare Market

The precision and durability of medical equipment are measured in microns. Orthotic devices, secure enclosures, implants, magnetic resonance imaging (MRI) machines, prosthetics, biopsy tubes, surgical scissors, implant holders, etc., have tight tolerance requirements in this sector.

Here, the Prototype CNC Machining process offers advantages over alternative methods by producing highly accurate and high-quality functioning prototypes. Prototype CNC Machining, which can accommodate demands for components made of metal and plastics, is also widespread in the medical business.

Production of Automobiles

The automotive industry is well suited for Prototype CNC Machining. These prototypes will be tested for functionality and fit in the vehicle before going into mass production.

Furthermore, the automotive sector requires precision gear and other elements. Prototypes made with CNC machining may be guaranteed to meet all design and functionality requirements.

Aerial Manufacturing

An increase in drag or wear on some aircraft parts could result from a minor mistake in the aerospace sector. This would fail these components while the plane is in flight. Before installing the region into a real aircraft, the Prototype CNC Machining will help ensure its proper operation. In addition, it delivers components with high accuracy and precision.

Prototype CNC Machining is routinely used in the aerospace industry to test the effectiveness and novelty of new components and materials. Prototype CNC Machining is widely used in the aerospace sector to produce many parts.

The Military-Industrial Complex

The military and defense sector also makes extensive use of CNC prototyping. Prototypes are needed for most munitions and military vehicles since their operation requires complex mechanisms. This prototype works best when CNC is machined. Prototype CNC Machining produces various parts for aircraft, transportation, communication, ammunition, and other technologies used in the military and defense industries.

Energy and Oil Markets

The oil business requires robust components because of the need to mine for resources at significant depths below the earth’s surface. These components are manufactured by computer numerical control machining. The energy sector can benefit from Prototype CNC Machining to investigate green energy sources with less environmental impact.

Business in Construction and Architecture

Interior and exterior parts are frequently machined using CNC technology in the architecture and construction industries. Using injection molds to perform the procedure increases both production time and cost. However, prototypes built using Prototype CNC Machining have made the process quicker and cheaper.

Advantages of CNC Machining for Prototypes

CNC machining for rapid prototyping allows for the speedy and accurate creation of prototypes, engineering models, and high-quality final products, all of which benefit significantly from computerized equipment. Some benefits of Prototype CNC Machining for your next quick prototype are discussed below.

Quick and effective

Rapid and effective, Prototype CNC Machining allows you to see your ideas come to life quickly. CNC machines can soon turn 3D models into actual objects with minimal human monitoring. This form of Prototype CNC Machining allows for faster delivery of final products to clients because of its shorter development cycles.

Superlative in terms of accuracy and precision

This method of Prototype CNC Machining yields far more accurate results than others. It can be put to use in the fabrication of components that require a high degree of accuracy. The surface quality can be enhanced by using modern finishing methods. This makes it ideal for producing high-precision parts in science and technology.

Flexible to change

It’s normal for some parts of a product to need rethinking if problems are discovered during development. Thanks to Prototype CNC Machining, this is a breeze. Just rebuild the original CAD file and install some updated software to fix the machine. This shortens the time it takes to get the product ready for market.

Doesn’t need any long-term equipment

Most prototyping methods require specialist, prefabricated tools. Hardening is possible, for instance, on injection molding dies. This might potentially add to production costs and cause delivery delays. None of these things are required for Prototype CNC Machining. The method centers around a revolving table that holds various tools. These items are easily interchangeable and can be used multiple times.

Stability and Repetition ability

Because CNC machines are computer-controlled, they can consistently reproduce the same parts. The CNC machines always produce large quantities with minimal variation in size. Because of this, it is an excellent option for manufacturing assemblies where tight tolerances are required.

The Challenges of Prototyping with CNC Machining

For all the above reasons, CNC machining is the preferred method for making prototypes. Because of the limitations inherent in this approach, it may not be a good fit for some applications. Consider a few examples.

Additional Expenses for 3D Printing

CNC machining is more costly than other prototyping processes, such as 3D Printing. Due to its complex nature and the necessity for trained operators, the CNC prototype comes at a higher price. The essential ingredients, including metals, can cost significantly more than required for 3D Printing. Therefore, engineers and product designers must consider various quick prototyping approaches before choosing one.

Waste Products

Prototype CNC Machining and other subtractive manufacturing methods. This method involves starting with a large chunk of material to create the prototype and then gradually trimming away excess until the desired shape is achieved. Naturally, this leads to excessive waste, which harms the environment and raises the cost of production. Quite a few machine businesses salvage metal from old projects and sell it for profit.

Limitations Considering Geometry

Cutting and shaping complex components is now a breeze with the help of modern CNC machines like 5-axis milling machines. These devices aren’t yet sophisticated enough to handle all possible designs. This sort of intricate internal geometry is characteristic of a troublesome prototype. In some cases, you won’t be able to insert the cutter. In these situations, alternative prototyping techniques like additive manufacturing are more valuable.

Conclusion

Prototype CNC Machining makes it feasible to quickly create metal prototypes with high mechanical quality and excellent structural integrity. However, 3D Printing shines when creating prototypes for vetting and improving designs before going into total production.