In the trend of modern manufacturing, plastic molding technology can be described as a well-deserved “superstar”. Its ability to transform simple plastic particles into a wide variety of products, whether you are an automotive manufacturer, electronics developer, or a key player in the medical industry, plastic molding is bringing great change and opportunity to your business.

If you’re new to plastic molding, or just want to learn more about the field, congratulations, you’ve come to the right place! In this article, we’ll take you inside the world of plastic molding, focusing on one of the most widely used injection molding techniques.

The charm and application of plastic molding

In this era of rapid development of science and technology, the importance of plastic molding technology is self-evident. It is a sharp tool in the manufacturing industry, bringing many plastic products that can not be separated from daily life. Whether it is a beautiful mobile phone case or a convenient food packaging, it is inseparable from the clever use of plastic molding. In the automotive, medical, electronics and other industries, plastic molding is an important supporter of product innovation and performance improvement.

Types of plastic molding

In the world of plastic molding, there are a variety of technologies, each with its own unique advantages and application scenarios. Blow molding, extrusion molding, injection molding, etc., they all play a unique role in different fields. Let’s take a brief look at several common plastic molding methods:

Injection molding

This is the most common plastic molding technique! Think of it like turning plastic into chocolate candy. First of all, it is a method in which the plastic material is first heated and melted in the heating cylinder of the injection molding machine, and then the melt is pushed into the cavity of the closed mold by the reciprocating screw. It can not only produce high-precision, high-quality products under high productivity, but also can process many plastic varieties, large output (about 1/3 of the total plastic) and wide use, therefore, injection molding is one of the important molding methods in plastic processing.

Blow molding

Blowing (expanding film) molding (or hollow blowing) refers to a molding method that blows hot thermoplastic billets or sheets in a closed die into hollow products by means of fluid (compressed air) pressure.

Blow molding is mostly used to make hollow plastic products, such as plastic bottles, containers, and some plastic pipes. The process is like blowing up a balloon. The plastic particles are melted and then injected into the mold, which has a cavity, and then the plastic is blown with air pressure until the plastic is tight to the surface of the mold, and after cooling and solidifying, you can take out a perfect plastic container!

But the basic steps of the blow molding process are:

1.Melt the material

2.The molten resin is formed into tubes or billets

3.Melt and seal the hollow billet in the blow mold

4.Blow up the in-mold billet

5.Cool blow molded products

6.Remove the product from the mold

7.Trim

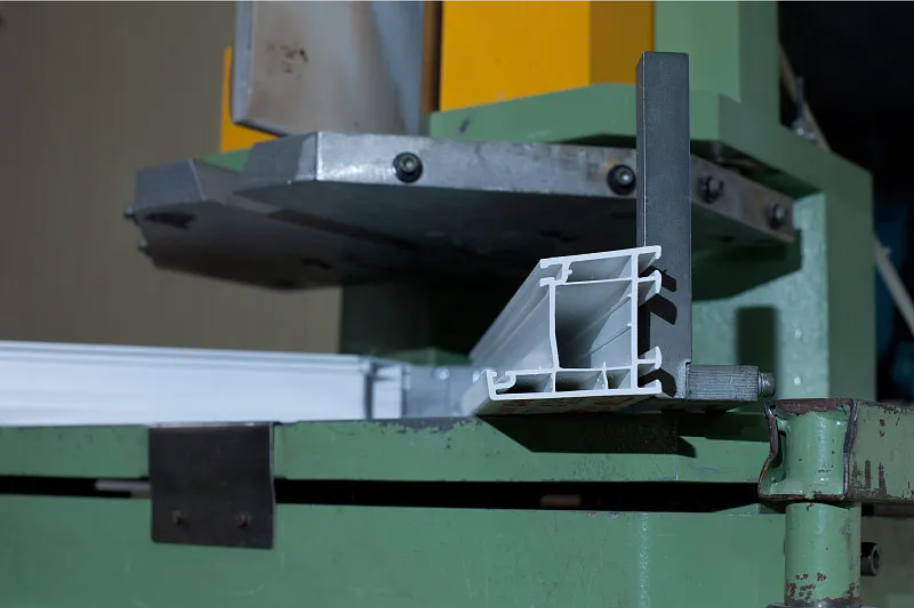

Extrusion molding

Extrusion is the method by which the plastic is continuously formed through the mouth mold in a flowing state by heating and pressurizing in the extruder.

This method is often used to produce long plastic products, such as pipes and films. Like squeezing toothpaste, the molten plastic is squeezed through a mold to form the desired shape, and then allowed to cool and solidify. This technology can be used for mass production, efficient and convenient!

Compression Molding

Compression molding is a method suitable for manufacturing large and simple shaped plastic products. It’s like giving plastic a big hug with a mold. First, plastic particles are placed in an open mold and then pressed together with a top mold. Then, under the action of high temperature and pressure, the plastic will become the shape you want. This method is often used to make large plastic products, such as car parts.

Injection molding principle and process introduction

Let’s dig into the magic principle of injection molding now! It is the technology of choice for plastic molding because it is suitable for a wide variety of plastics and can produce complex and diverse products.

Polypropylene (PP) injection molding process

PP, commonly known as polypropylene, is also known as “folding glue” because of its good breaking resistance. PP is a semi-transparent, semi-crystalline thermoplastic with high strength, good insulation, low water absorption, high thermal deformation temperature, low density and high crystallinity. Modified fillers are usually glass fiber, mineral fillers, thermoplastic rubber and so on.

The liquidity of PP for different purposes is very different, and the flow rate of PP generally used is between ABS and PC.

Pure PP is translucent ivory white and can be dyed in a variety of colors. PP dyeing in general injection molding machine can only use color masterbatch. Individual plasticizing elements that enhance mixing on some machines can also be dyed with toner. Products used outdoors are generally filled with UV stabilizers and carbon black. The use of recycled materials should not exceed 15%, otherwise it will cause strength decline and decomposition discoloration. PP injection molding generally does not require special drying treatment.

There is no special requirement for the selection of injection molding machine. Because PP has high crystallinity. It is necessary to use a computer injection molding machine with high injection pressure and multi-stage control. The clamping force is generally determined by 3800t/m2, and the injection volume is 20%-85%.

Mold temperature 50-90℃, for high size requirements with high mold temperature. The core temperature is more than 5℃ lower than the cavity temperature, the diameter of the flow channel is 4-7mm, the length of the pin gate is 1-1.5mm, and the diameter can be as small as 0.7mm. The shorter the length of the edge gate, the better, about 0.7mm, the depth is half of the wall thickness, the width is twice the wall thickness, and the length of the molten flow in the mold cavity increases gradually.

The mold must have good exhaust, the vent depth is 0.025mm-0.038mm, the thickness is 1.5mm, to avoid contraction marks, it is necessary to use a large and round nozzle and circular flow channel, and the thickness of the reinforcement should be small (such as 50-60% of the wall thickness). The thickness of products made of homopolymer PP should not exceed 3mm, otherwise there will be bubbles (thick wall products can only be copolymerized PP).

The melting point of PP is 160-175 ° C and the decomposition temperature is 350 ° C, but the temperature can not be set above 275 ° C during injection processing, and the temperature of the melting section is best at 240 ° C.

In order to reduce internal stress and deformation, high-speed injection should be selected, but some grades of PP and molds are not suitable (bubbles, gas marks). Low speed injection and high die temperature are used if the patterned surface appears light and dark streaks diffused by the gate.

Available 5bar melt back pressure, color powder back pressure can be adjusted.

High injection pressure (1500-1800bar) and holding pressure (about 80% of the injection pressure) are used. About 95% of the total travel time to change the pressure holding, with a longer pressure holding time.

In order to prevent shrinkage and deformation caused by post-crystallization, products generally need to be soaked in hot water.

Polyethylene (PE) injection molding process

PE is a crystalline raw material with minimal hygroscopic properties, no more than 0.01%, so there is no need for drying before processing. PE molecular chain flexibility is good, the interbond force is small, the melt viscosity is low, and the fluidity is excellent, so the molding can be formed without too high pressure. The shrinkage range of PE is large, the shrinkage value is large, and the directivity is obvious, the LDPE shrinkage rate is about 1.22%, and the HDPE shrinkage rate is about 1.5%. Therefore, it is easy to deformation and warping, and the cooling conditions of the mold have a great influence on the shrinkage rate, so the mold temperature should be controlled to keep the cooling uniform and stable.

The crystallization capacity of PE is high, and the temperature of the mold has a great influence on the crystallization status of the plastic parts. The mold temperature is high, the melt cooling is slow, the crystallinity of the plastic parts is high, and the strength is high.

The melting point of PE is not high, but the specific heat capacity is large, so more heat needs to be consumed when plasticizing, so the plasticizing device is required to have a larger heating power in order to improve production efficiency. The softening temperature range of PE is small, and the melt is easy to oxidize, so contact between the melt and oxygen should be avoided as much as possible in the molding process, so as not to reduce the quality of plastic parts.

PE parts are soft in texture and easy to demoulding, so when the plastic parts have shallow side grooves, they can be strongly demoulding. The non-Newtonian property of PE melt is not obvious, the change of shear rate has little effect on the viscosity, and the viscosity of PE melt is also little affected by temperature. The cooling rate of PE melt is slower, so it must be sufficiently cooled. The mold should have a good cooling system.

If the PE melt is injected with a direct feed port, the stress should be increased and the deformation of uneven shrinkage and obvious directionality should be increased, so attention should be paid to the selection of feed port parameters. PE molding temperature is wide, in the flow state, a little fluctuation in temperature has no effect on injection molding. PE has good thermal stability, generally no obvious decomposition phenomenon below 300 degrees, and has no impact on quality.

PE main forming conditions

Barrel temperature: Barrel temperature is mainly related to the density of PE and melt flow rate, in addition to the type and performance of the injection molding machine, the shape of the first grade plastic parts. Because PE is a crystalline polymer, the grain should absorb a certain amount of heat during melting, so the barrel temperature should be 10 degrees higher than its melting point. For LDPE, the barrel temperature is controlled at 140-200℃, the barrel temperature of HDPE is controlled at 220℃, the minimum value is taken at the back of the barrel, and the maximum value is taken at the front end.

Mold temperature: Mold temperature has a greater impact on the crystallization status of plastic parts, high mold temperature, high melt crystallinity, high strength, but the shrinkage rate will also increase. Usually, the mold temperature of LDPE is controlled at 30℃-45℃, and the temperature of HDPE is correspondingly 10-20℃ higher.

Injection pressure: Increase injection pressure is conducive to the filling of molten material, because the fluidity of PE is very good, so in addition to thin-walled slender products, should be a good choice of lower injection pressure, the general injection pressure is 50-100MPa. The shape is simple. For larger plastic parts behind the wall, the injection pressure can be lower, and vice versa.

Polyvinyl chloride (PVC) injection molding process

Typical applications: water supply pipe, household pipe, house wall panel, commercial machine shell, electronic product packaging, medical equipment, food packaging, etc.

Chemical and physical properties: PVC material is an amorphous material. PVC materials are often added to the actual use of stabilizers, lubricants, auxiliary processing agents, colors, impact agents and other additives. PVC material has non-flammability, high strength, climate resistance and excellent geometric stability.

PVC has a strong resistance to oxidants, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid, concentrated nitric acid and is not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

The melting temperature of PVC is a very important process parameter during processing, and if this parameter is improper, it will lead to the problem of material decomposition. The flow characteristics of PVC are quite poor, and its process range is very narrow.

In particular, large molecular weight PVC materials are more difficult to process (this material is usually added to improve the flow characteristics of lubricants), so small molecular weight PVC materials are usually used. The shrinkage rate of PVC is quite low, generally 0.2-0.6%.

Injection mold process conditions:

Drying treatment: Usually no drying treatment is required.

Melting temperature: 185~205℃ Mold temperature: 20~50℃.

Injection pressure: up to 1500bar.

Holding pressure: up to 1000bar.

Injection speed: In order to avoid material degradation, it is generally necessary to use a considerable injection speed.

Runner and gate: All conventional gates can be used. If processing smaller parts, it is best to use a pinpoint gate or a submerged gate; For thicker parts, it is best to use a fan gate. The minimum diameter of the pinpoint gate or the submerged gate shall be 1mm; The thickness of the fan gate should not be less than 1mm.

Chemical and physical properties: Rigid PVC is one of the most widely used plastic materials.

Polystyrene (PS) injection molding process

Typical applications: product packaging, household goods (tableware, trays, etc.), electrical (transparent containers, light source scatters, insulating films, etc.).

Chemical and physical properties: Most commercial PS are transparent, amorphous materials. PS has very good geometric stability, thermal stability, optical transmission characteristics, electrical insulation characteristics and very small moisture absorption tendency. It is resistant to water, diluted inorganic acids, but can be corroded by strong oxidizing acids such as concentrated sulfuric acid, and can expand and deform in some organic solvents. Typical shrinkage ranges from 0.4 to 0.7%.

Injection mold process conditions:

Drying treatment: Unless improperly stored, drying is usually not required. If you need to dry it, the recommended drying condition is 80 ° C for 2 to 3 hours.

Melting temperature: 180~280℃. For flame-retardant materials, the upper limit is 250℃.

Mold temperature: 40~50℃.

Injection pressure: 200~600bar.

Injection speed: A fast injection speed is recommended.

Runner and gate: All conventional gate types can be used.

ABS injection molding process

Typical applications: automobiles (instrument panels, tool hatches, wheel covers, mirror boxes, etc.), refrigerators, high-strength tools (hair dryers, mixers, food processors, lawn mowers, etc.), telephone casings, typewriter keyboards, recreational vehicles such as golf carts and jet sledges.

Chemical and physical properties :ABS is synthesized from three chemical monomers: acrylonitrile, butadiene and styrene. Each monomer has different characteristics: acrylonitrile has high strength, thermal stability and chemical stability; Butadiene has the properties of toughness and impact resistance. Styrene is easy to process, high finish and high strength. In terms of morphology, ABS is a non-crystalline material.

The polymerization of the three monomers produces a terpolymer with two phases, one is a continuous phase of styrene-acrylonitrile and the other is a dispersed phase of polybutadiene rubber. The characteristics of ABS mainly depend on the ratio of the three monomers and the molecular structure in the two phases. This allows for great flexibility in product design, and has resulted in hundreds of different quality ABS materials on the market. These different quality materials provide different characteristics, such as medium to high impact resistance, low to high finish and high temperature distortion characteristics.

ABS material has superior machinability, appearance characteristics, low creep and excellent dimensional stability and high impact strength.

Injection mold process conditions:

Drying treatment: ABS materials are hygroscopic and require drying before processing. The recommended drying condition is 80 to 90 ° C for at least 2 hours. The material temperature should be less than 0.1%.

Melting temperature: 210~280℃; Recommended temperature: 245 ° C.

Mold temperature: 25~70℃. (The mold temperature will affect the finish of the plastic parts, and a lower temperature will result in a lower finish).

Injection pressure: 500~1000bar.

Injection speed: medium to high speed.

conclusion

There are various kinds of plastic molding technology, and injection molding, as an important method, has a wide range of application prospects. For the manufacturing industry and consumers, the development of plastic molding will bring us more high-quality and functional plastic products.

If you have developed a strong interest in plastic molding and are looking for professional and reliable injection molding services, then Longsheng Injection Molding is your best partner!

Whether you need to produce automotive parts, electronic device casings, medical device parts or other plastic products with complex shapes, we can tailor your solutions to ensure that your needs are met.