Anodizing Services

We use different types of anodizing, such as Type II polar oxidation and Type III anodizing, which can be customized according to the requirements of the product.

Anodizing type II

All tolerances apply after anodizing

| Project | Info |

|---|---|

| Materials | Aluminum |

| Colors | Clear, black, you can define your color according to RAL. |

| Glossiness | Glossy or matte |

| Texture | Smooth, matte finish. |

| Thickness | 0.00007” to 0.0010” |

| Surface roughness | Ra 0.4μm to 1.2μin |

| Hardness | 250-500 HV(The hardness range can be adjusted as needed) |

| Heat resistance | 150°C(302°F) |

| Application | Improve hardness, increase surface wear resistance, and enhance aesthetics |

Anodizing type III

All tolerances apply after anodizing.

| Project | Info |

|---|---|

| Materials | Aluminum |

| Colors | Clear, Black |

| Glossiness | Glossy or matte |

| Texture | Smooth, matte finish. |

| Thickness | 0.0005” to 0.0045” |

| Surface roughness | Ra 0.5μm to 3.0μin |

| Hardness | 450-600 HV(The hardness range can be adjusted as needed) |

| Heat resistance | 200°C(392°F) |

| Application | Used to improve the corrosion resistance, wear resistance, and appearance of metal parts |

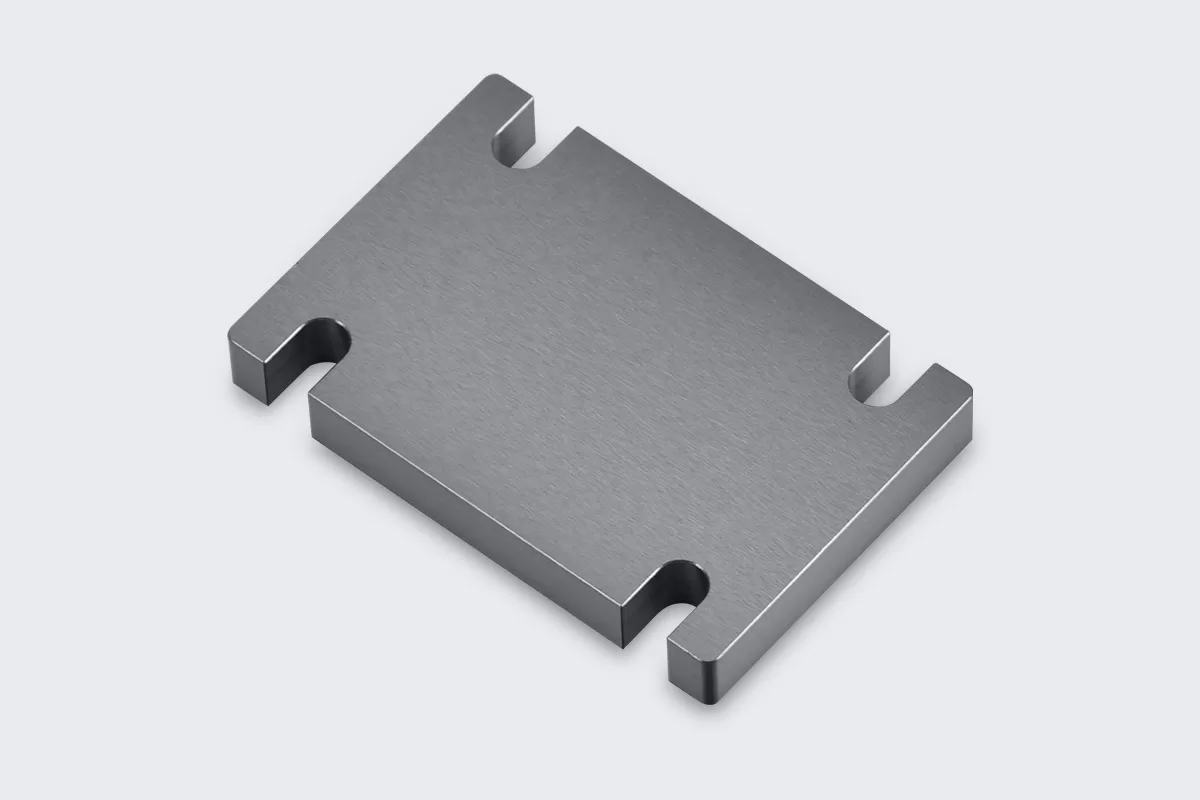

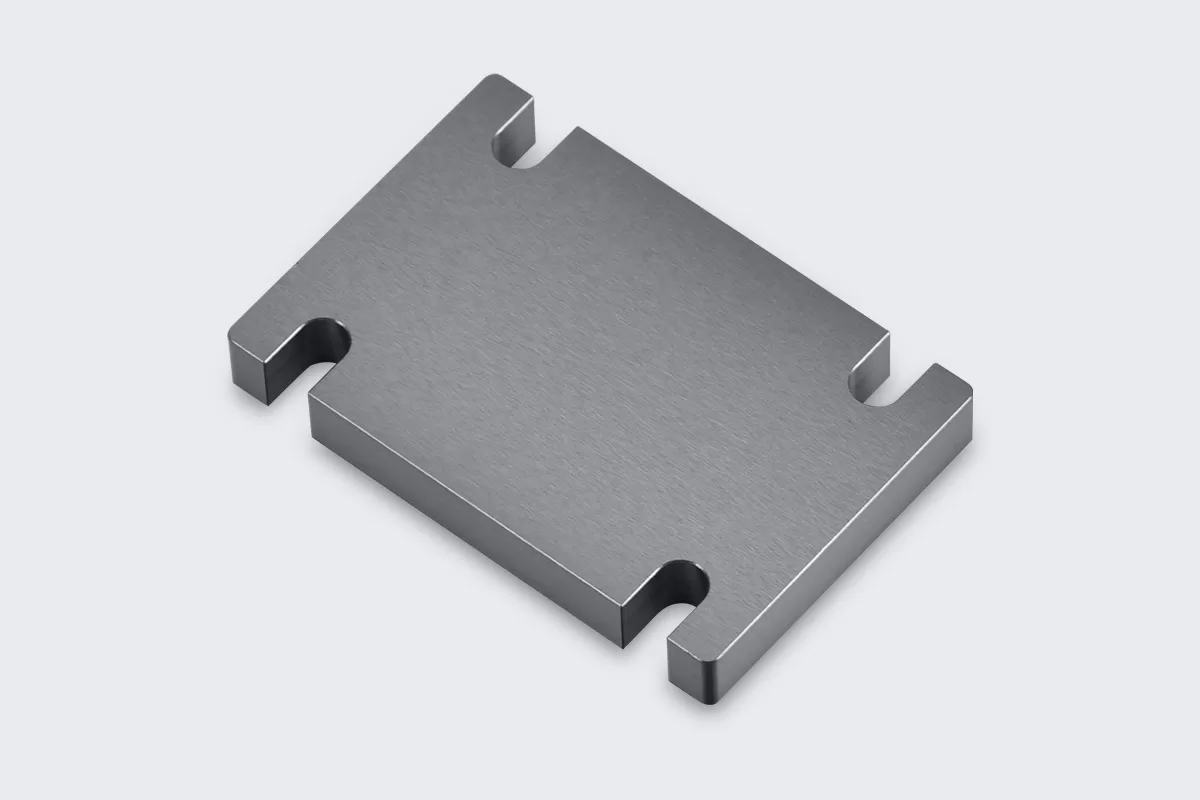

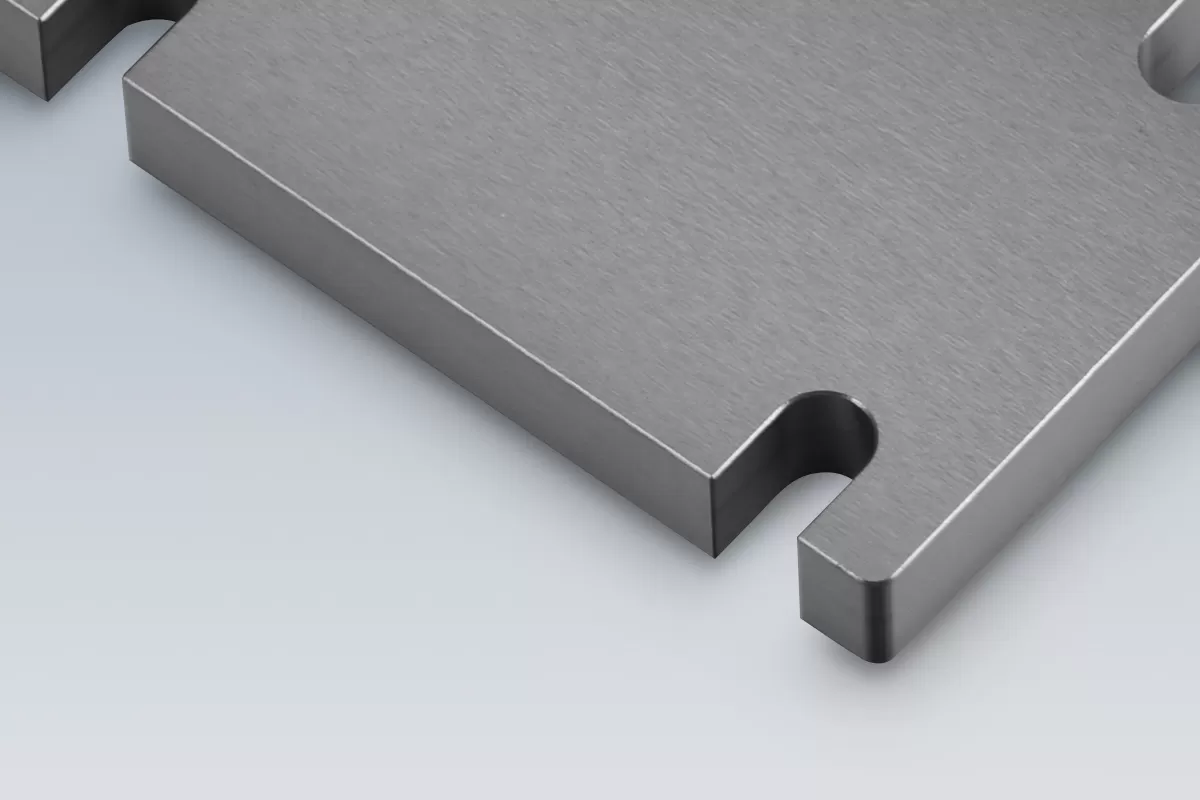

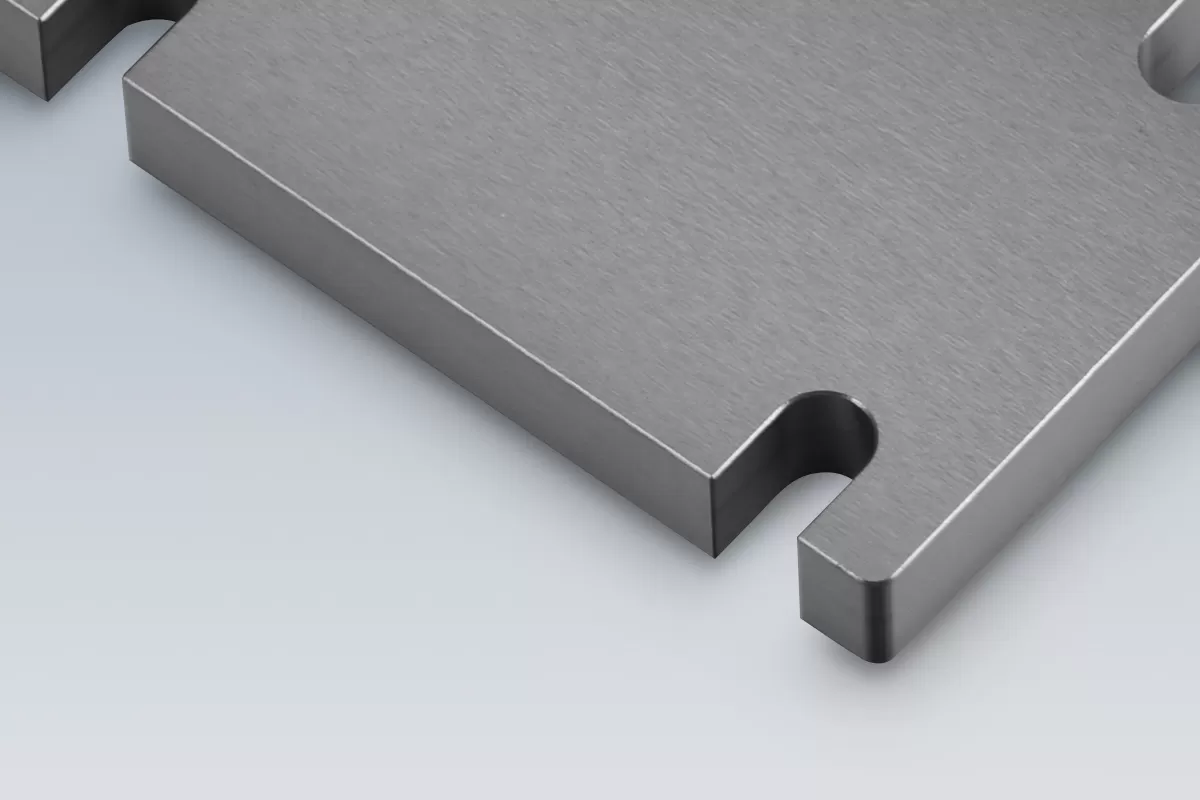

Example of anodizing parts

Design considerations for anodized parts

- Increase the thickness of the part surface: Anodizing will form a layer of oxide on the surface of the metal part, which will increase the surface thickness. This may have an impact on the size and functionality of the parts, so it is recommended to block and cover threads, reams, or other critical surfaces before anodizing to ensure that their functionality is not affected.

- Shelf marks: If the parts do not have holes, they may be hung on the conductive frame for anodizing treatment using spring clips, wire wrapping, or other methods. This may result in leaving small areas without oxidation treatment, known as “shelf marks”. If these areas have a significant impact on product performance, they need to be marked in the drawing to remind operators.

- Conductivity: Anodizing will form an insulation layer, so the conductivity of the treated parts is poor. This needs to be considered in design and engineering to ensure that the electrical connections of the parts are not disturbed.

- Rounding edges and corners: To prevent local overheating and burning caused by current concentration, all sharp corners on the workpiece should be rounded off. This can improve the uniformity and efficiency of the processing process.

- Surface roughness: After hard anodizing treatment, the surface roughness may decrease, making the parts smoother. But if the workpiece already has a very smooth surface, it may lose some smoothness.

- Special fixtures: Due to the high voltage and current required for hard anodizing, special fixtures must be designed to ensure good conductive contact of the workpiece. Otherwise, breakdown or burning of the contact part of the workpiece may occur, thereby affecting the treatment effect.

Latest Blog Posts

Types of Thread Taps: How to Choose the Right One?

2025-04-28

Choosing the right thread tap requires comprehensive consideration of four key factors: processing materials, hole characteristics, production batch and precision requirements. For hard materials such ...

Read More →

What Grounds Jets? Brake Discs & Retraction Actuators Under Fire

2025-04-25

The core causes of frequent groundings of jet aircraft are the thermal decay effect of brake discs and hydraulic hysteresis of retraction actuators: Emirates Boeing ...

Read More →

Landing Gear Struts & Wheel Axles: 7 Critical Factors for Aircraft Safety

2025-04-24

As the core load-bearing components for aircraft take-off and landing, the reliability of landing gear struts and axles is directly related to flight safety. Key ...

Read More →

Put your parts into production today

- All information and uploads are secure and confidential.