Black Oxide Services

We provide black oxide coatings to improve the appearance of metal surfaces, reduce reflection, improve corrosion resistance, and improve the lubrication of metal parts.

Black Oxide Specifications

| Project | Info |

|---|---|

| Applicable materials | Steel, stainless steel, copper |

| Colors | Black |

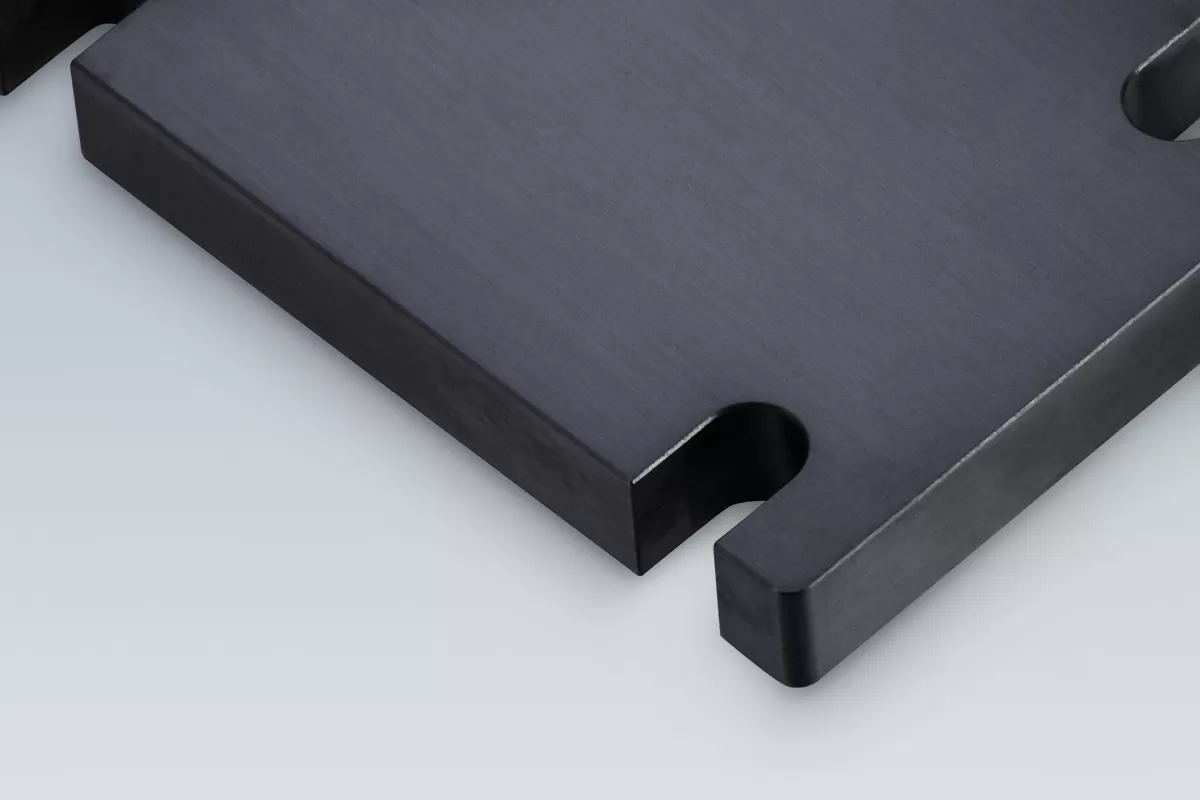

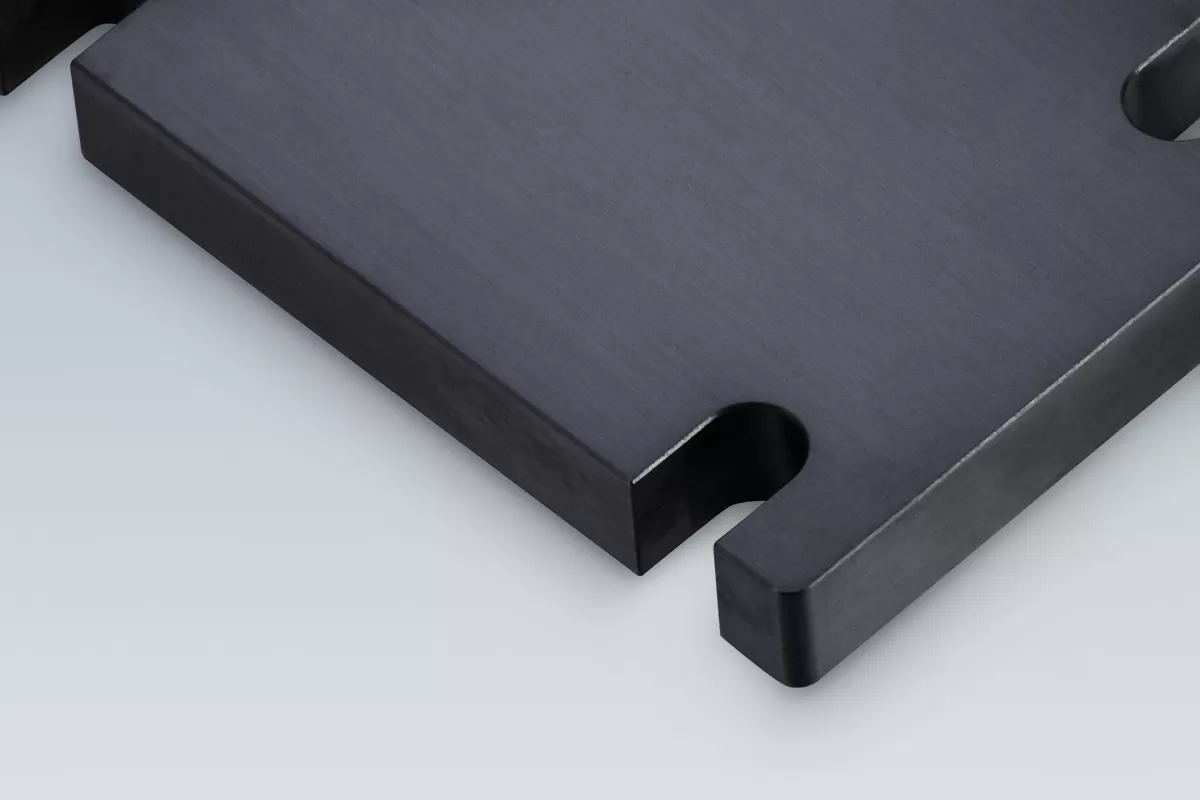

| Texture | Smooth black, shiny black, matte black |

| Thickness | 0.5-25μm |

| Protective coating (optional) | Oil immersion, sealing or other additional coatings |

| Application industry | Tools, automotive parts, fasteners, and decorative items |

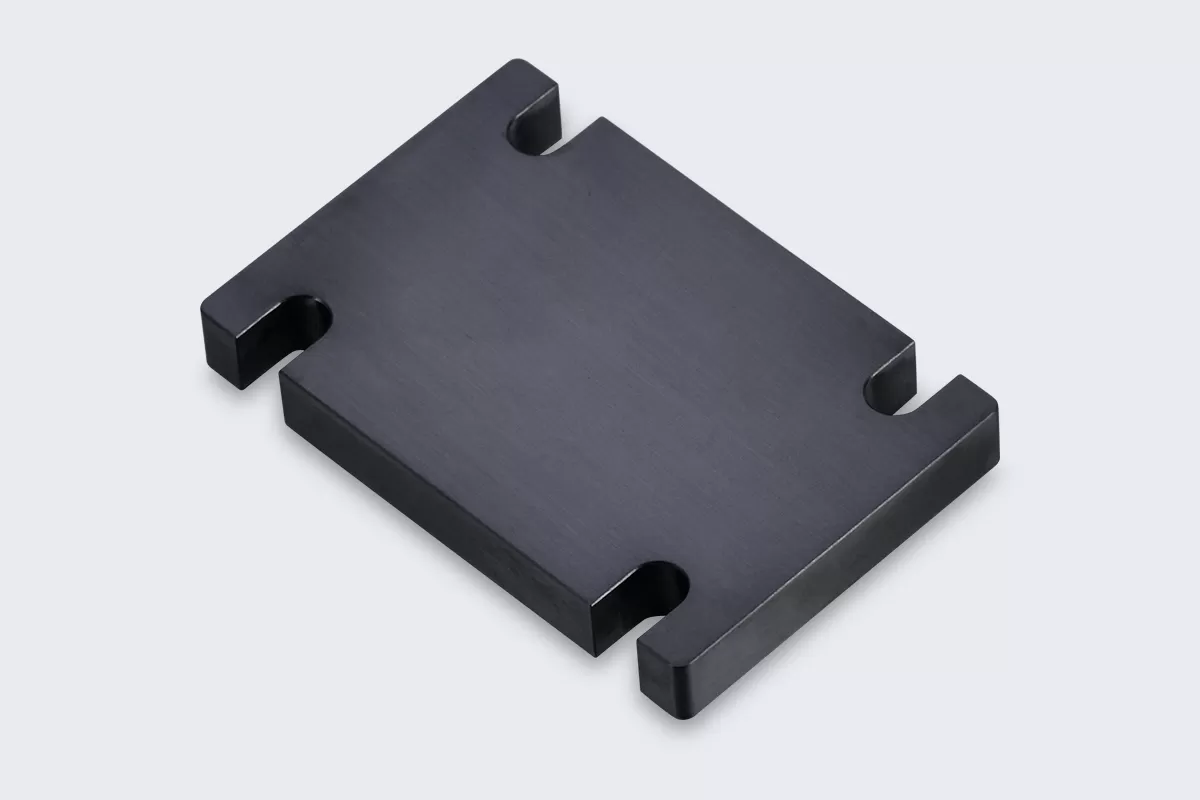

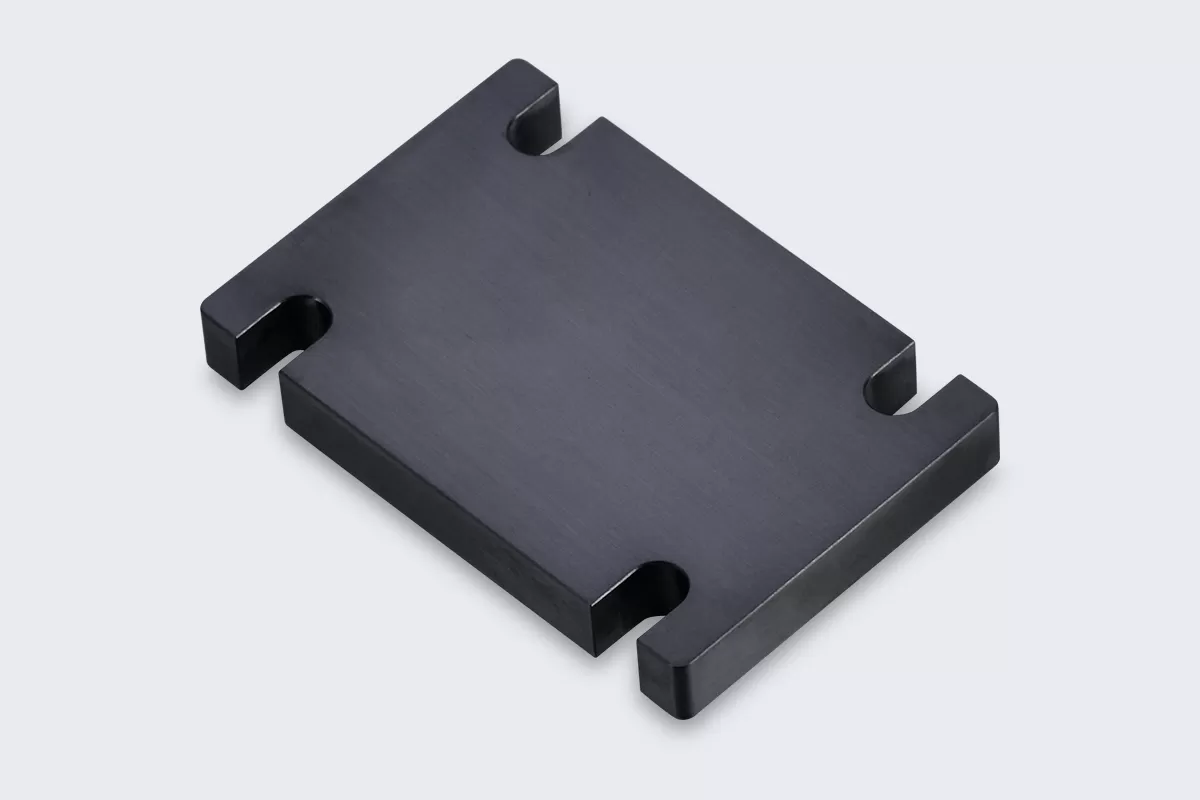

Example Of A Black Oxide Parts

About Black Oxide

Black oxide, also known as blackening (similar to Alodine) , is a chemical conversion coating used to provide a layer of black corrosion protection on various types of metal surfaces, particularly steel and iron.

The process of black oxide involves immersing parts in a hot bath containing various chemicals to convert the surface of the material into magnetite, thereby forming a black oxide layer. This process will not have a significant impact on the size of the parts, so there is no need for special steps to cover or cover the parts.

In addition, the black oxide immersed in oil can provide higher corrosion resistance. Because after the black oxide, a layer of oil film is usually applied, which helps to provide additional corrosion protection and reduce contact between the metal surface and the external environment.

Latest Blog Posts

Types of Thread Taps: How to Choose the Right One?

What Grounds Jets? Brake Discs & Retraction Actuators Under Fire

Landing Gear Struts & Wheel Axles: 7 Critical Factors for Aircraft Safety

Put your parts into production today

- All information and uploads are secure and confidential.