A bead blast is a process that uses tiny beads to smooth and polish the surface of a material. After CNC machining, bead blasting is the final finishing process that gives a part its desired finish.

In this comprehensive guide, we’ll answer all your questions about bead blasting, including what it is, how it works, the pros and cons, tips, and more.

What is Bead Blasting?

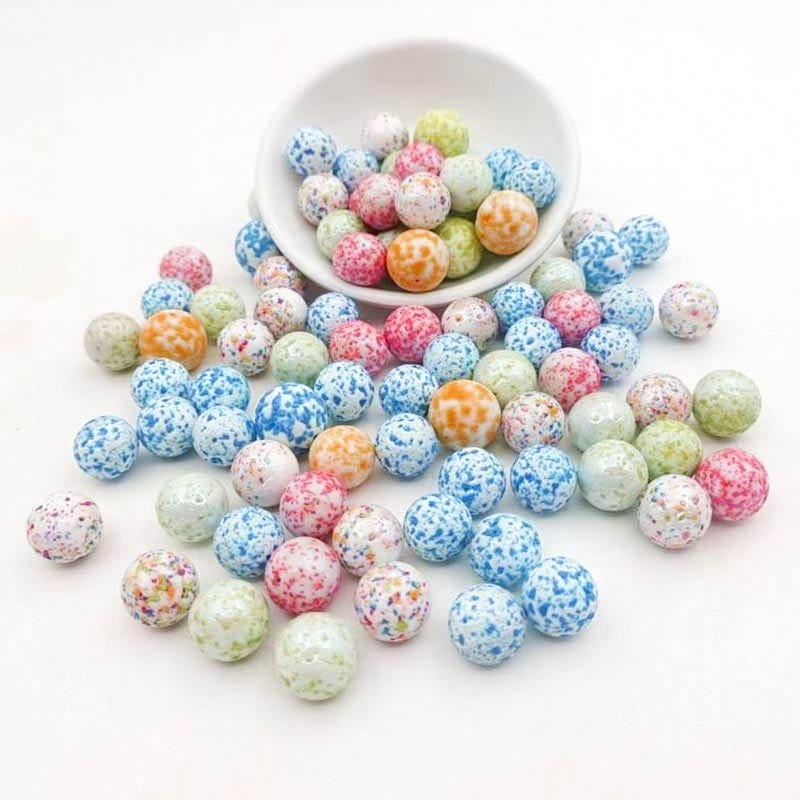

Bead blasting is a surface treatment process that involves shooting tiny, spherical beads at high velocity onto a surface to remove contaminants,

smooth rough surfaces, or create a matte finish. The beads used in bead blasting can be made from various materials such as glass, ceramic, plastic, or metal. The process is typically carried out using a specialized machine called a bead blaster, which propels the beads using compressed air or centrifugal force. Bead blasting is commonly used in industries such as automotive, aerospace, and manufacturing to prepare surfaces for painting, remove rust or scale, and improve the overall appearance and quality of the surface.

How Does Bead Blasting Work?

A bead blast propels tiny beads at high velocity onto a surface to achieve the desired effect. Here is a step-by-step explanation of how the process works:

- Preparation: The surface to be bead blasted is thoroughly cleaned and prepared to remove any loose debris, grease, or contaminants. This ensures that the beads can effectively impact the surface and achieve the desired result.

- Bead Selection: The appropriate type and size of beads are selected based on the desired outcome and the material of the treated surface. Different materials and sizes of beads will have varying effects on the surface, such as removing rust, smoothing rough surfaces, or creating a matte finish.

- Bead Blasting Equipment: A bead blasting machine, also known as a bead blaster, is used for the process. The machine consists of a blasting cabinet or chamber, a nozzle or gun, and a source of compressed air or centrifugal force to propel the beads.

- Bead Propulsion: The beads are loaded into the blasting chamber, and the machine is activated. Compressed air or centrifugal force is used to propel the beads through the nozzle or gun at high velocity toward the surface being treated.

- Impact and Abrasion: As the beads strike the surface, they combine impact and abrasion. The effect of the beads helps to dislodge contaminants, rust, or scale from the surface, while the abrasion action smoothens rough surfaces or creates a matte finish.

- Containment and Recovery: To prevent the beads and debris from scattering, the blasting chamber is enclosed, and a vacuum or recovery system is used to collect the used beads and debris. This allows for easy disposal or recycling of the beads.

- Inspection and Finishing: After the bead blasting process, the surface is inspected to ensure the desired outcome. Additional finishing steps such as cleaning, painting, or coating may be required depending on the application.

Overall, bead blasting is a practical and versatile surface treatment process that can be used for various applications, ranging from cleaning and preparation to surface finishing and restoration.

What Materials are Used for Bead Blasting?

Various materials can be used as blasting media for bead blasting, depending on the specific application and desired outcome. Here are some common materials used for bead blasting:

1.Glass Beads: Glass beads are one of the most commonly used blasting media. They are made from soda-lime glass and are available in different sizes. Glass beads are versatile and can be used for cleaning, deburring, and creating a smooth, satin-like finish on various surfaces.

2.Ceramic Beads: Ceramic beads are made from zirconia or alumina and are known for their durability and hardness. They are often used for aggressive cleaning, surface preparation, and removing tough coatings or rust from metal surfaces.

3.Plastic Beads: Plastic beads, typically made from acrylic or urea, are used for delicate or sensitive surfaces that require gentle cleaning or surface preparation. They are non-abrasive and can remove paint, coatings, or contaminants without damaging the underlying material.

4.Aluminum Oxide: Aluminum oxide is a popular blasting media for applications that require aggressive cleaning or surface preparation. It is a sharp, rigid material that can effectively remove rust, scale, and paint from metal surfaces.

5.Steel Shot: Steel shot consists of small, spherical pellets made from hardened steel. It is commonly used for heavy-duty applications such as removing heavy rust, scale, or coatings from metal surfaces. Steel shot is highly durable and can be reused multiple times.

6.Walnut Shells: Walnut shells are a natural and biodegradable blasting media. They are commonly used for gentle cleaning, deburring, and polishing applications. Walnut shells are non-abrasive and are suitable for delicate surfaces such as wood, plastic, or fiberglass.

These are just a few examples of the materials used for bead blasting. The choice of blasting media depends on factors such as the surface material, desired outcome, level of aggressiveness required, and environmental considerations.

Bead Blasting vs. Sand Blasting

Both bead and sandblasting are similar in that both are media blasting methods and sometimes serve identical purposes. However, each has its advantages and disadvantages. Below, we’ve outlined the key differences to help you make the best choice for your project.

Bead Blasting

Bead blasting accelerates spherical media, usually made from glass, at high speeds toward a work surface. The media’s round shape has a peening action and leaves small dimples. The dimples are like tiny mirrors that scatter and reflect the light in the viewer’s direction. This gives the part a uniform and bright, satin-like look.

Pros

- No free silica or silica dust

- Materials that are gentle on the skin

- Does not affect part dimensions

- The media is usually highly reusable for multiple cycles

Cons

- Remove paint and coatings slowly

- Surfaces are not etched for painting adhesion

- On more complex materials, slow down the work.

Sand blasting

Sandblasting is an abrasive blasting method that is more traditional. Silica sand particles are propelled at high pressures towards the workpiece. Sand particles with an irregular shape can easily etch and cut surfaces. Sandblasting is used for removing surface contaminants like rust and corrosion. Silica sand may still be used in some instances, but other types of abrasive materials are replacing it due to its potential health hazards. Abrasion-blasted parts are usually duller than bead-blasted ones.

Pros

- Removes paint and coatings very quickly

- Etching surfaces can be used to prepare them for painting.

- Work on the most durable materials

Cons

- Using sand media can cause health problems (e.g., Silicosis).

- Not suitable for materials or components that are fragile

- It can result in the removal of material, which may affect the part dimensions.

Tools Used for a Bead Blast Finish

A bead blast finish is a popular surface finish technique for custom-machined parts. It involves using media blasting to achieve the desired surface texture. The tools used for a bead blast finish include:

1.Bead Blasting Media: The choice of media is crucial for achieving the desired bead blast surface finish. The two commonly used beads for bead blasting are glass and steel.

- Glass Beads: Glass beads are made from lead-free, soda-lime glass and are shaped into spheres. They are more eco-friendly and can be recycled multiple times. Glass bead blasting is gentler than other abrasive blasting methods.

- Steel Beads: Steel beads are made from molten steel and are designed into round objects using a round die. They are less expensive alternatives and allow for several recycling cycles. Steel beads are more effective at eliminating unwanted textures from metal surfaces.

2.Bead Blaster Cabinet: A bead blaster cabinet is used as a containment system for the bead blasting process. It comes in various sizes, from small tabletop units to large industrial-sized units. The cabinet has a viewing window allowing the operator to see the work. Bead blaster cabinets are quieter than traditional sandblasting equipment, making them suitable for use where noise levels must be kept low.

3.Blast Nozzle: The blast nozzle is an essential tool used to direct the flow of the abrasive media onto the workpiece. It is designed to withstand the high-pressure environment of the bead blasting process.

4.Gloves: Gloves are worn by operators to protect their hands from the abrasive media and ensure safety during the bead blasting process.

These tools and the appropriate techniques and best practices contribute to achieving a high-quality bead blast finish.

Pros and Cons of Bead Blast Finish

Bead blasting is a surface finishing technique that uses tiny beads to create a smooth and textured surface on various materials. Here are the pros and cons of bead blast finish:

Pros:

- Safe Process: Bead blasting is safer than other blasting methods.

- Environmentally Friendly: The bead blasting process is environmentally friendly, especially when using glass beads, as they are lead-free and can be recycled multiple times.

- Alternative to Sandblasting: Glass bead blasting is often used as an alternative to sandblasting, providing a gentler, more controlled surface finish.

- Suitable for Delicate Components: Bead blasting is excellent for delicate components, as it does not cause damage or distortion to the material.

- Versatile: Bead blasting can be applied to various materials, including aluminum, stainless steel, titanium, copper, brass, and plastics.

Cons:

- Not Suitable for Tough Materials: Bead blasting may not be suitable for rigid materials, as it may take longer to achieve the desired finish.

- Limited Longevity: The bead blast finish may not last as long as steel blast media, requiring more frequent reapplication.

- No Profile for Paint Adherence: Glass beads used in bead blasting do not leave any profile on the surface, making it challenging for paint to adhere correctly.

Considering these pros and cons when deciding whether to use a bead blast finish for your project is essential. Bead blasting has advantages in terms of safety, environmental friendliness, and versatility, but it may only be suitable for some materials and require more frequent maintenance.

Applications of Bead Blast Finish

Bead blast finishing is a surface treatment process widely utilized across various industries to achieve a uniform, matte surface with a soft satin reflection and low reflectivity. This report synthesizes the bead blast finish applications based on several sources’ provided key points.

- Aircraft Components: Bead blast finishing is commonly used as a preparatory step before painting aircraft components. This ensures a clean surface for better paint adhesion and a more consistent finish.

- Automotive Parts: Similar to its use in the aerospace industry, bead blast finishing is applied to automotive parts to prepare them for a fresh coat of paint. This treatment is essential for achieving a streak-free finish crucial for panel-to-panel matching in the automotive sector.

- Military Components: The military sector also benefits from bead blast finishing for various components. The process is suitable for creating a non-reflective surface on military hardware, which can be a tactical advantage.

- Medical Applications: Bead blast finishing is applied to aluminum parts used in medical applications. The resulting finish is clean and consistent, which is vital for medical devices requiring high hygiene and precision standards.

- Food, Beverage, and Pharmaceutical Industries: The process is also widely used in the food, beverage, medical, and pharmaceutical industries, where a clean and aesthetically pleasing finish is necessary for both functional and decorative applications.

In conclusion, bead blast finishing is a critical process in manufacturing that serves multiple purposes, from preparing surfaces for painting to ensuring a clean and consistent appearance for medical devices and consumer products. Its non-directional finish and low reflectivity make it an ideal choice for industries where aesthetics and function are essential.

Blasting Media Selection Chart

Regarding bead blasting surface finish, the choice of media is critical to getting the desired results. The following blasting media selection chart compares the effectiveness and properties of different media types for various applications. This can help you determine the best media type for your project.

| Glass Bead | Steel Shot | Ceramic Shot | Aluminum Oxide | Garnet | Plastic Media | |

| Cleaning / Removal | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ |

| Peening | ✔️ | ✔️ | ✔️ | — | — | — |

| Surface Etching | — | — | — | ✔️ | ✔️ | ✔️ |

| Recyclability / Media Life | Medium | High | Very-High | Med-High | Med-Low | Medium |

| Probability of Material Removal | Very Low | Very Low | Very Low | Med-High | Medium | Very Low |

| Mohs’ Hardness | 5.5 | 6-7.5 | 7 | 44782 | 8 | 44624 |

| Typical Blast Pressure (PSI) | 20-55 | 20-90 | 20-90 | 20-90 | 30-80 | 20-60 |

| Media Shape | ⬤ | ⬤ | ⬤ | ▲ | ▲ / ⬤ | ▲ |

| ✔️ = Suitable, ⬤ = Spherical, ▲ = Angular | ||||||

Best Practices for Specifying Media Blast Finishes

When specifying media blast finishes for various applications, it is essential to consider the type of media, grit size, surface roughness, and other factors to achieve the desired outcome. Here are the best practices based on the latest research and expert advice:

- Specify the Media and Grit Size: Clearly define the type of media and grit size to be used in the blasting process. Different media types, such as glass beads, aluminum oxide, or steel grit, will produce different finishes. For example, delicate glass beads create a satin-like finish, while aluminum oxide gives a uniform but duller appearance.

- Consider Material and Chemical Composition: The selection of blast media should be based on the material and chemical composition, hardness, density, shape, and size of the media and the component to be blasted. This ensures compatibility and prevents damage to the substrate.

- Use the Least Aggressive Media Possible: To reduce wear on equipment and lower maintenance expenses, choose the least aggressive media that will still achieve the planned work. This also helps conserve energy and minimize abrasive consumption.

- Avoid Tight Surface Roughness Callouts: Maintaining tight surface roughness requirements with media blasting is challenging. A general recommendation is to limit surface roughness to no lower than 32 µin Ra for a smooth bead blasted part.

- Masking Notes for Critical Features: Include clear instructions for masking areas that should not be blasted, such as sealing surfaces, o-ring grooves, and threaded features, to protect them from abrasion.

- Use the Lowest Pressure Possible: Employ the lowest pressure or turbine speed that will still complete the task to save energy and reduce wear and tear on the blasting equipment.

- Preparation Before Blasting: Ensure that oxides, rust, or other contaminants are removed from the surface before applying the bead blast finish to achieve a clean and consistent result.

- Provide a Boundary Sample or High-Resolution Photos: Supplying a boundary sample or detailed images can help manufacturers understand the expected finish and reduce the need for overly detailed notes.

- Avoid Using Sand: It should be avoided as a blasting medium due to health risks associated with silica and the potential for equipment damage due to moisture content.

- Consider Environmental and Safety Factors: Glass bead blasting is environmentally friendly and allows for recycling before replacement. It is also a safer process compared to other blasting methods like sandblasting.

- Choose Media Based on the Application: Different applications may require specific media types. For instance, walnut shells or corn cobs are suitable for softer surfaces like wood, while silicon carbide is ideal for fast etching of hard surfaces.

- Understand the Impact of Media on Surface Profile: The depth profile created by the blasting media is crucial for coating adhesion. The right abrasive is the finest grade to impart the required depth profile.

By following these best practices, you can ensure that the specified media blast finish meets the functional and aesthetic requirements of the application, whether it’s for aerospace components, automotive parts, military hardware, or medical devices.

LongSheng’s High-Quality Finishing Services

Bead blasting finish is one of the best finishing choices for your applications. However, having your project in the wrong hands may prove harmful. So, you should be able to search for experience and expertise. The best company that offers a perfect mix of both is LongSheng.

LongSheng has years of experience offering cost-effective surface finish solutions for various industries. We offer an extensive array of materials and finishes, including metal plating. Our team of experts works with you to create a custom metal finishing procedure. This way, you can be sure of high-quality services that meet your unique needs.

We prioritize customer satisfaction at LongSheng. All our services come at competitive rates. All you have to do is contact us or upload your design file today. You will receive an instant quote, and we are ready to work.

Best Bead Blasting Tips for the Perfect Bead Blast Finish

Achieving the perfect bead blast finish requires attention to detail, equipment, and an understanding of the process. Here are the best tips compiled from various expert sources to help you get the best results every time.

- Select the Right Media and Grit Size: The choice of media—glass, ceramic, or plastic beads—will influence the finish, from satin to dull. The grit size also plays a crucial role in determining the final appearance and texture of the surface.

- Quality Equipment Matters: Invest in a high-quality bead blaster cabinet that is durable, has sturdy legs, seamless sealing, and protected view windows. This ensures a consistent finish and the longevity of your equipment.

- Safety is Paramount: Always prioritize safety by wearing protective clothing, gloves, goggles, and dust masks. Please ensure you can use proper ventilation and familiarize yourself with the equipment handbook before starting.

- Environmental Considerations: Glass bead blasting is environmentally friendly and provides a corrosion-resistant finish that lasts. It’s a sustainable choice for surface finishing.

- Machine Specifications: When choosing a bead blaster, consider the size of the cabinet, the type of blast nozzle, and the power source. These factors will affect the efficiency and quality of the finish.

- Surface Preparation: Thoroughly clean the surface of any oxides, rust, or contaminants before blasting. This ensures a clean and consistent result.

- Technique and Settings: Use the correct blasting pressure, maintain a consistent nozzle distance, and adjust the machine settings according to the material and bead type for optimal results.

- Masking Critical Areas: Use appropriate masking techniques to protect areas that should not be blasted, such as sealing surfaces and threaded features.

- Post-Blasting Cleaning: After blasting, cleaning the surface thoroughly to remove any remaining impurities is essential. This can be done with compressed air or a mild detergent.

- Documentation and Samples: Provide precise specifications for the media and grit size, and consider supplying a boundary sample or high-resolution photos to help manufacturers understand the expected finish.

- Media Compatibility: Ensure the selected media is compatible with the material being blasted to avoid damaging the substrate.

- Avoid Over-Specifying: Be cautious with tight surface roughness callouts, as bead blasting may only sometimes achieve excellent finishes. A general guideline is to limit surface roughness to 32 µin Ra.

- Maintenance and Troubleshooting: Regular and thorough maintenance of bead blasting equipment is necessary for consistent performance. Be prepared to troubleshoot common issues to maintain efficiency and quality.

- Technological Advancements: Stay informed about the latest advancements in bead blasting technology, such as automation and robotics, which can increase precision and efficiency.

- Comparing Finishing Techniques: Understand how bead blasting compares with other finishing techniques to make an informed decision based on the specific needs of your project.

By following these tips, you can ensure a superior bead blast finish that meets aesthetic and functional requirements. Whether you’re working on automotive parts, military equipment, or medical devices, these best practices will guide you to achieve the desired outcome with bead blasting.

Comprehensive Research Report: Bead Blast Finish FAQs

Equipment and Media

The equipment used for bead blasting includes cabinets of various sizes, from small tabletop units to large industrial-sized units. These cabinets are quieter than traditional sandblasting equipment, making them suitable for noise-sensitive environments. Bead blaster guns, which can be handheld or benchtop models, direct the media to the surface. The abrasive media, small spheres blasted at high pressure, come in different sizes and materials, including glass, steel, aluminum oxide, and plastic.

Environmental and Safety Considerations

Bead blasting is environmentally friendly, as many glass beads are made from non-contaminating materials. It is also considered safer than sandblasting due to lower dust generation and the absence of free silica. Safety measures, such as gloves, eye protection, and respirators, are essential when bead blasting.

Applications and Benefits

Bead blasting has many applications across industries, including automotive, aerospace, military, and medical. It is used for peening, deburring, cosmetic finishing, and preparing metal surfaces for secondary finishes like powder coating and painting. The process offers several benefits, such as providing soft, smooth, and even finishes, improving mechanical strength and aesthetics, and being versatile enough to work with various materials like stainless steel, aluminum, and cast iron.

Challenges and Limitations

Despite its many advantages, bead blasting can be time-consuming, especially for large surface areas. It may also have limitations for applications requiring strict tolerances 3. Achieving a consistent and desired surface profile can be challenging, particularly on irregular or complex shapes. Embedding abrasive particles into the substrate is also risky and may require additional cleaning steps.

Best Practices for Bead Blasting

Selecting the correct abrasive material and grit size is essential to achieve the best results. Low pressure should be used to prevent damage to the workpiece. Preparing the surface by removing oxides or rust before applying the bead blast finish is crucial. Masking notes for critical features should be included in the specifications to protect them from abrasion. Providing a boundary sample or high-resolution photos can also help achieve consistent results.

Conclusion

Bead blasting is a common and effective surface finish process often included in technical requirements due to its versatility and ability to improve a part’s appearance and physical properties. By understanding the process, equipment, media, and best practices, manufacturers can ensure high-quality finishes that meet the specific needs of their applications.