CNC machining and casting are two distinct strategies used within the manufacturing of steel parts, every with its personal set of traits and benefits. CNC machining is a subtractive process the place materials is faraway from a stable block of steel utilizing numerous slicing instruments to attain the specified form. This methodology is understood for its precision, means to provide complicated geometries, and wonderful floor end. Alternatively, casting entails pouring molten steel right into a mold the place it solidifies into the required form. Casting is useful for producing giant portions of parts, particularly these with intricate inside cavities that may be tough to machine.

Within the realm of steel fabrication, CNC machining and casting stand as pillars of recent manufacturing strategies. Whereas each processes serve the widespread goal of making steel parts, they diverge considerably of their strategy. CNC machining, characterised by its precision and flexibility, sculpts steel into the ultimate product via a subtractive methodology. In distinction, casting molds the way forward for steel parts by pouring and solidifying molten materials. This text delves into the nuanced variations between these two methodologies, shedding gentle on their distinctive benefits and appropriate purposes within the business.

What’s CNC machining?

CNC machining is a producing process through which pre-programmed pc software program directs the motion of manufacturing unit instruments and equipment. CNC stands for “Pc Numerical management,” and this machining permits a wide range of complicated machines, akin to milling machines, lathes, laser cutters, and water knives, to routinely carry out detailed slicing duties. This expertise improves on historically manually managed processes by growing accuracy, complexity and repeatability whereas lowering human error.

CNC machines can be utilized to chop steel, plastic, wooden, glass, foam and composite materials in a variety of purposes from automotive manufacturing to aerospace, development and electronics. Designs are created utilizing CAD (computer-aided design) software program after which transformed into applications particular to CNC machines that may exactly manufacture parts and parts in accordance with preset parameters and designs.

What’s casting?

Casting is a producing process the place a liquid materials is normally poured right into a mold, which comprises a hole cavity of the specified form, after which allowed to solidify. The solidified part is also referred to as a casting, which is ejected or damaged out of the mold to finish the process. Casting materials are normally metals or numerous time setting materials that remedy after mixing two or extra parts collectively; examples are epoxy, concrete, plaster and clay. Casting is most frequently used for making complicated shapes that may be in any other case tough or uneconomical to make by different strategies.Casting is a producing process the place a liquid materials is normally poured right into a mold, which comprises a hole cavity of the specified form, after which allowed to solidify. The solidified part is also referred to as a casting, which is ejected or damaged out of the mold to finish the process. Casting materials are normally metals or numerous time setting materials that remedy after mixing two or extra parts collectively; examples are epoxy, concrete, plaster and clay. Casting is most frequently used for making complicated shapes that may be in any other case tough or uneconomical to make by different strategies.

Materials:CNC Machining vs Casting

When deciding on materials for CNC machining and casting, components to think about embody the fabric’s mechanical properties, value, machining problem, and last software. Right here is a straightforward desk itemizing some widespread materials and their suitability for every processing methodology:

| Materials Kind | CNC Machining Suitability | Casting Suitability |

|---|---|---|

| Aluminum Alloy | Excessive | Excessive |

| Steel | Excessive | Medium |

| Copper | Medium | Excessive |

| Magnesium Alloy | Medium | Medium |

| Plastics | Low | Excessive |

CNC machining is mostly appropriate for parts that require excessive precision and sophisticated shapes. Casting is appropriate for producing giant portions, easy shapes, or giant parts. Every materials has particular properties, akin to aluminum alloy being light-weight however robust, making it appropriate for the aerospace and automotive industries; steel is extensively utilized in numerous equipment and development buildings on account of its sturdiness and cost-effectiveness.

Precision:CNC Machining vs Casting

-

CNC Machining vs. Casting – Precision Comparability Desk

| Process Kind | Precision Vary | Advantages | Disadvantages |

|---|---|---|---|

| CNC Machining | ±0.005 mm | Excessive precision, robust repeatability | Greater value |

| Casting | ±0.1 mm | Low value, appropriate for mass manufacturing | Decrease precision, greater defect charge |

-

Detailed Precision Evaluation Desk

| Process Kind | Tolerance Grade | Floor Roughness | Relevant Conditions |

|---|---|---|---|

| CNC Machining | IT7-IT8 | Ra 0.8-1.6 | Excessive-precision parts |

| Casting | IT13-IT14 | Ra 12.5-25 | Massive or complex-shaped parts |

-

Precision Comparability Chart

| Process Kind | Precision | Value-Effectiveness | Manufacturing Pace |

|---|---|---|---|

| CNC Machining | Excessive | Medium | Quick |

| Casting | Medium | Excessive | Gradual |

Value:CNC Machining vs Casting

-

CNC Machining vs. Casting – Value Comparability Desk

| Process Kind | Unit Value | Preliminary Funding | Upkeep Value |

|---|---|---|---|

| CNC Machining | Excessive | Excessive | Medium |

| Casting | Low | Medium | Low |

-

Financial Effectivity Evaluation Desk

| Process Kind | Manufacturing Effectivity | Materials Utilization | Vitality Consumption |

|---|---|---|---|

| CNC Machining | Excessive | Excessive | Excessive |

| Casting | Medium | Low | Medium |

-

Value-Profit Comparability Chart

| Process Kind | Manufacturing Value | Operational Value | Whole Value |

|---|---|---|---|

| CNC Machining | Excessive | Medium | Excessive |

| Casting | Medium | Low | Medium |

Applicability:CNC Machining vs Casting

-

CNC Machining vs. Casting – Applicability Comparability Desk

| Process Kind | Applicability | Appropriate Materials | Relevant Industries |

|---|---|---|---|

| CNC Machining | Small to giant batches | Metals, plastics, and so on. | Aviation, automotive, precision gear |

| Casting | Massive batches | Iron, steel, aluminum, and so on. | Building, artwork, giant equipment |

-

Area of Software Evaluation Desk

| Process Kind | Precision Requirement | Design Complexity | Manufacturing Cycle |

|---|---|---|---|

| CNC Machining | Excessive | Excessive | Quick |

| Casting | Low to medium | Low to medium | Lengthy |

-

Applicability Comparability Chart

| Process Kind | Flexibility | Customization Means | Mass Manufacturing |

|---|---|---|---|

| CNC Machining | Excessive | Excessive | Reasonable |

| Casting | Low | Low | Excessive |

How to decide on distinction between cnc machine steel and cast steel?

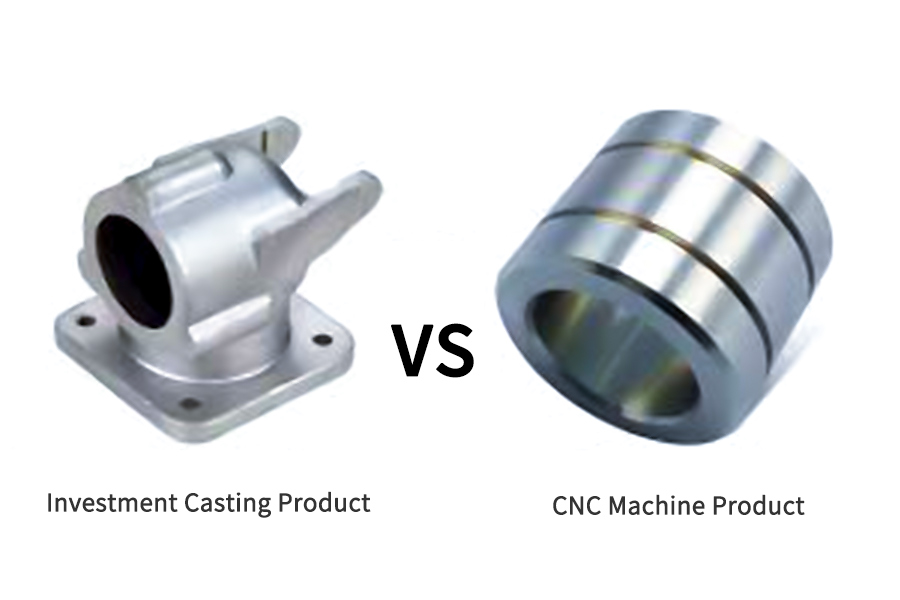

The principle distinction between CNC machined steel and cast steel lies within the manufacturing process and the traits of the ultimate product. Here is a comparability of the 2, together with how to decide on the process that fits your wants:

CNC Machined Metal:

- Manufacturing process: Makes use of pc numerical management machines to exactly take away materials to attain the specified form and dimensions.

- Precision: Very excessive, able to attaining very tight tolerances.

- Floor high quality: Easy, with well-handled particulars.

- Value: Greater for small batch manufacturing.

- Applicability: Appropriate for complicated designs and small batch manufacturing requiring excessive precision.

Cast Metal:

- Manufacturing process: Entails pouring molten steel into molds, which solidifies into the specified form upon cooling.

- Precision: Comparatively decrease, because the casting process can contain shrinkage and warping.

- Floor high quality: Could require additional processing to enhance the floor.

- Value: Decrease for giant batch manufacturing.

- Applicability: Appropriate for giant batch manufacturing and parts with easy shapes.

The right way to Select:

- Contemplate precision necessities: For those who want extremely exact parts, CNC machining is the higher selection.

- Contemplate your funds: In case you are on a restricted funds and the manufacturing amount is giant, casting is perhaps extra economical.

- Contemplate design complexity: Complicated designs may require CNC machining to attain.

- Contemplate the fabric: Some materials might solely be appropriate for particular manufacturing processes.

Why select LongSheng in your process?

Causes for selecting LongSheng may embody:

- Technical Experience: LongSheng might possess superior CNC machining expertise and intensive business expertise.

- High quality Assurance: LongSheng might provide high-quality merchandise with strict high quality management processes.

- Buyer Service: Glorious customer support and good after-sales help might be certainly one of LongSheng’s strengths.

- Customization Functionality: LongSheng might present customized companies, able to producing particular parts in accordance with buyer wants.

- Value-Effectiveness: LongSheng might provide aggressive costs on account of its environment friendly manufacturing processes.

Conclusion

The distinction between CNC machined steel and cast steel is primarily mirrored within the manufacturing process and the traits of the completed product. CNC machining makes use of pc numerical management expertise to exactly take away materials, creating parts with excessive precision and easy surfaces, appropriate for complicated designs and small batch manufacturing. Casting entails pouring molten steel into molds to form the specified form, appropriate for mass manufacturing of simple-shaped parts, however the precision and floor high quality could also be decrease. The selection between these processes is determined by the product’s precision necessities, design complexity, manufacturing quantity, and funds. LongSheng, as a provider, could also be most popular for its technical experience, high quality assurance, customer support, customization capabilities, and cost-effectiveness.

FAQs

What steel is the best to CNC?

For CNC machining, aluminum is commonly the best steel to work with. It has common hardness and good thermal conductivity, which can forestall overheating all through machining. Furthermore, aluminum requires a lot much less chopping energy and causes a lot much less placed on on devices, making it a hottest selection for CNC machining.

How does a CNC machine cut back steel?

The process of a CNC machine chopping steel normally consists of the subsequent steps: First, engineers design the wished part shapes on a computer. These shapes are then translated proper right into a CNC programming language, akin to G-code. This code is enter into the CNC machine, which follows the instructions to hold out the chopping. In the middle of the chopping process, the software program strikes all through the ground of the workpiece, eradicating additional materials and forming the required form.

What is the worth of CNC machining steel?

The worth of CNC machining steel varies primarily based totally on a variety of components, along with the type and measurement of the chosen materials, the complexity of the machining, and the required precision. Sometimes, parts which are extra advanced and require elevated precision will value additional. Specific costs ought to be obtained from the machining producer.

Why is CNC stronger than casting?

CNC machining and casting are two completely different manufacturing methods. CNC machining is a chopping process that will precisely create the design’s form, whereas casting consists of pouring molten steel proper right into a mold and allowing it to relax and form the form. Parts made by means of CNC machining are usually stronger than these made by the use of casting because of CNC machining can protect the steel’s integrity, whereas casting can introduce bubbles or impurities that impact the ability of the part.

Helpful useful resource