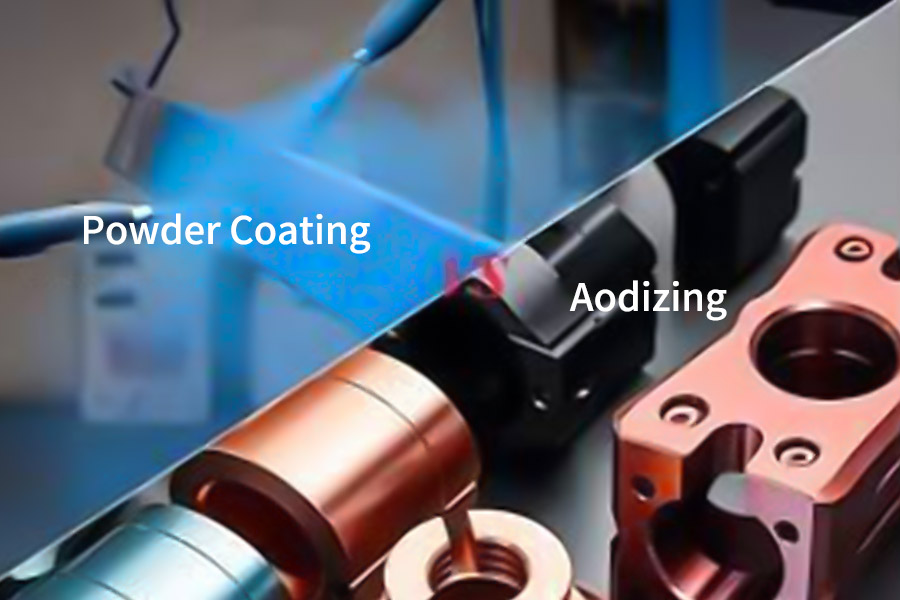

Within the huge ocean of recent industrial design, we regularly encounter two mysterious materials—black anodized aluminum and powder-coated aluminum. These materials, like two shiny stars, shine their very own gentle within the limitless universe. However what precisely are the variations between them? Let’s carry the veil of thriller and discover out.

First, we have to perceive that these two floor therapy applied sciences should not nearly making metals look extra enticing. The scientific ideas behind them, in addition to the traits they communicate to the materials, are the results of cautious choice by engineers and designers.

Black Anodized Aluminum:

- Definition: Anodizing is an electrochemical process that creates a thick oxide layer on the floor of aluminum. When this process entails particular dyes and subsequent sealing steps, it ends in black anodized aluminum.

- Traits:

- Corrosion Resistance: The oxide layer successfully prevents the aluminum substrate from coming into contact with moisture and oxygen within the surroundings, enhancing corrosion resistance.

- Hardness: The oxide layer is extraordinarily laborious, almost gem-level, making it appropriate for functions that require put on resistance.

- Insulation: The oxide layer has good insulating properties, making it appropriate for digital gadget casings or elements.

- Aesthetics: Black anodized aluminum has a easy metallic texture and uniform colour, which is visually interesting.

Powder Coated Aluminum:

- Definition: Powder coating is a ending process the place dry powder paint is evenly utilized to the aluminum floor by electrostatic or friction strategies, then baked at excessive temperatures to form a stable coating.

- Traits:

- Shade Variety: Powder coating offers a wide range of colour choices to satisfy totally different design wants.

- Environmentally Pleasant: Powder coating doesn’t include unstable natural compounds (VOCs), making it environmentally pleasant.

- Economical: In comparison with different coating processes, powder coating typically has decrease prices, and the coating thickness is controllable.

- Applicability: Powder coating is appropriate for numerous aluminum merchandise, particularly people who require climate resistance and UV safety for outside use.

Black Anodized Aluminum Vs Powder Coated Aluminum

| Function | Black Anodized Aluminum | Powder Coated Aluminum |

|---|---|---|

| Sturdiness | Excessive hardness, proof against scratches and put on | Sturdy, however could chip underneath excessive put on |

| Aesthetics | Easy metallic sheen, long-lasting colour that resists fading | Wide selection of colours, however could fade over time if uncovered |

| Eco-friendliness | Fewer chemical compounds used, extra environmentally pleasant | No liquid solvents, however requires security measures throughout manufacturing and utility |

| Utility Vary | Utilized in functions requiring excessive put on resistance and exact dimensions, comparable to digital gadget casings | Appropriate for giant structural elements and outside furnishings |

Price-Effectiveness:

- Black Anodized Aluminum: Though the preliminary price could also be increased, its sturdiness might make it more cost effective in the long term.

- Powder Coated Aluminum: Decrease preliminary price, however could require extra frequent upkeep or alternative, particularly when used outside.

Upkeep and Cleansing:

- Black Anodized Aluminum: Sometimes requires solely cleaning soap and water for cleansing, with out the necessity for particular upkeep.

- Powder Coated Aluminum: May have particular cleaners to take away floor stains, particularly on tough powder coatings.

Environmental Adaptability:

- Black Anodized Aluminum: Proof against temperature adjustments and UV rays, appropriate to be used in a wide range of environments.

- Powder Coated Aluminum: Though additionally proof against UV rays and temperature adjustments, the coating could also be broken in excessive circumstances.

Manufacturing Time:

- Black Anodized Aluminum: The manufacturing process is comparatively longer because it takes time to form the oxide layer.

- Powder Coated Aluminum: Manufacturing is likely to be sooner for the reason that curing time for powder coating is shorter.

Each materials have their benefits and limitations. Black anodized aluminum performs higher when it comes to sturdiness and upkeep, whereas powder coated aluminum has benefits in price and manufacturing effectivity. The ultimate selection ought to be primarily based on particular utility necessities, funds, and anticipated environmental circumstances.

Utility

| Utility Area | Black Anodized Aluminum | Powder Coated Aluminum |

|---|---|---|

| Electronics | Smartphone, pill, and laptop computer casings | – |

| Aerospace | Parts for plane and satellites | – |

| Pictures Tools | Digital camera casings and tripods | – |

| Medical Units | Surgical instruments and medical tools | – |

| Building Trade | – | Window and door frames, curtain partitions, and architectural decorations |

| Automotive Trade | – | Car rims and trim items |

| Outside Furnishings | – | Patio furnishings and public seating |

| Sports activities Services | – | Health tools and stadium amenities |

Case Research

Case One: Smartphone Casings

- Black Anodized Aluminum: Apple’s iPhone collection extensively makes use of black anodized aluminum for its casings, not solely offering a premium look but additionally providing good put on resistance and warmth dissipation.

- Powder Coated Aluminum: Whereas not as widespread as anodized aluminum for smartphone casings, some customized cellphone manufacturers use powder coating to supply extra colour selections and personalised designs.

Case Two: Outside Furnishings

- Black Anodized Aluminum: As a result of its climate resistance and corrosion resistance, black anodized aluminum is appropriate for high-end outside furnishings, particularly in coastal or humid environments.

- Powder Coated Aluminum: With its number of colours and cost-effectiveness, powder-coated aluminum is commonly used for park benches, outside eating tables, and so on., particularly in settings that require colour coordination with the environment.

By means of these circumstances, we will see that black anodized aluminum excels in functions that require energy and sturdiness, whereas powder coated aluminum is extra fashionable in functions that want a wide range of colours and cost-effectiveness. Every materials has its distinctive benefits, appropriate for various markets and desires.

Conclusion

Black Anodized Aluminum:

- Options: Excessive put on resistance, glorious corrosion resistance, good insulation properties, and a easy, uniform metallic texture.

- Advantages: Appropriate for high-end merchandise that require excessive energy and exact dimensions, comparable to digital gadget casings and aerospace elements.

Powder Coated Aluminum:

- Options: Shade variety, environmentally pleasant, cost-effective, and relevant to a variety of merchandise and environments.

- Advantages: Appropriate for merchandise that want a wide range of colours and climate resistance, comparable to architectural decorations, automotive equipment, outside furnishings, and so on.

Within the manufacturing process, choosing the proper floor therapy know-how is essential. It impacts not solely the looks and efficiency of the product but additionally its sturdiness and market competitiveness. Subsequently, producers and designers want to pick out essentially the most applicable know-how primarily based on the appliance surroundings, anticipated lifespan, and aesthetic necessities of the shoppers.

Suggestions:

- For top-end merchandise that require excessive put on resistance and exact dimensions, black anodized aluminum is a superb selection.

- For merchandise that want a wide range of colours and good climate resistance, particularly these used outside, powder coated aluminum is likely to be the extra appropriate possibility.