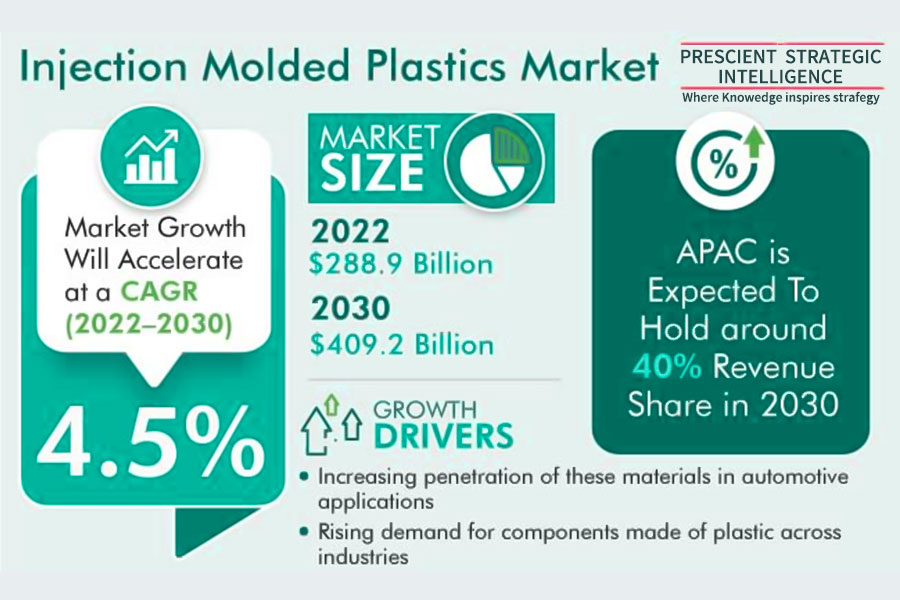

China’s injection services are widely recognized for their quality and competitive price structure. It provides affordable molding services due to advanced machinery, expertise and cheap labor. Injections are one of the more expensive to manufacture in terms of initial investment. Most of the budget is spent on mold making. This pricing scheme is not entirely suitable for China’s injection molding costs, which are optimized in every aspect. Injection molding prices in China are lower than in other regions. In this article, let’s explore what is the cheapest injection cost in China?

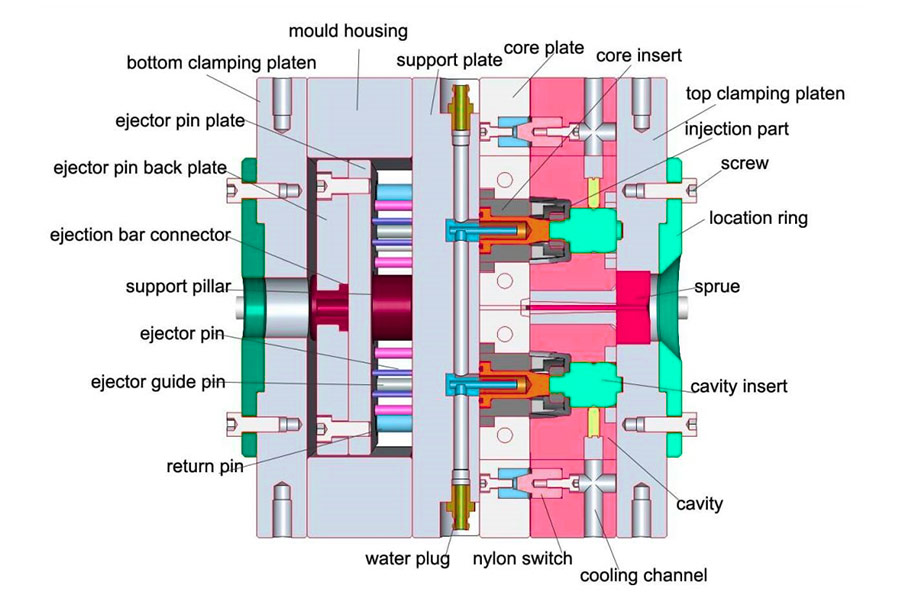

What is injection molding?

Injection molding is a manufacturing process involving the use of injection molding machines to produce products from thermoplastic or thermosetting materials. The process involves melting the material and then injecting it into a mold in the shape of the desired product. Once the material is cooled, the mold opens and the finished product is ejected.

Injection molding is a high precision and efficient process for producing a variety of products ranging from plastic toys to medical equipment and auto parts.

Basic knowledge of injection molding cost

- Material selection: Choose the right injection molding material, usually thermoplastic, to ensure its plasticity and durability.

- Mold design and fabrication: The molds are carefully designed to precisely match the product specifications.

- Melting process: melt the selected plastic into a liquid state.

- Injection: inject the liquid plastic into the mold under high pressure.

- Cooling and curing: The product is cooled and cured in the mold.

- Top out: the finished product tops out from the mold.

China injection molding cost

When it comes to the cost of custom injection molding in China, prices may vary depending on the scale of production and the quality of work required. The cost of injection molding in China will be between $1000 for small-scale production and $12000 for mass production, depending on the quality of the work. Outsourcing to large-scale processing in China may be a cost-effective alternative compared with other methods.

Why is China invincible in the field of injection molding?

There are three main reasons why China is leading in the injection molding industry: manufacturing infrastructure, technological advances, and skilled but low-cost labor. Its large-scale infrastructure dramatically reduces production costs. This is possible because Chinese companies can meet large-volume production demand. China’s continuous investment in advanced technology plays an important role in ensuring efficient and high-quality production. At the same time, the staff skillfully manage these advanced processes, contributing to the efficiency of the industry.

In addition, China’s injection molding industry has largely benefited from government support and global supply chain integration. Government policies and subsidies promote industry growth, while integration into the global markets is good for exports.

| Injection cost | Estimated value |

| Material | $600 |

| Design fee | $150 |

| Machining cost | $250 |

| Assembly, heat treatment, and mold testing | $120 |

| Expense of taxation | $185 |

| Total unaccrued profit | $1305 |

Injection Molding Cost Comparison: USA vs. China

- Raw material cost: The cost of the raw materials (such as plastic resin) required in the injection molding design process is more economical in the United States than in China.

- Labor costs: Because China has huge labor resources, its labor costs are lower than those of the United States. China’s economy is growing rapidly, so Chinese workers can get relatively low wages. American residents have a relatively high quality of life, which leads to higher salaries for their employees.

- Energy costs: Given China’s high dependence on coal, its energy costs are actually lower than those of the United States.

- Transportation costs: Although production costs in China are relatively low, the cost of shipping goods to the United States could be high. Therefore, to reduce transportation costs. When deciding on the site of production, the company must weigh the cost of transportation.

If you are looking for a reliable injection molding service provider in China, Longsheng is undoubtedly your first choice.We have accumulated valuable experience in providing high-quality injection molding services to customers in automotive, electronics, medical and other fields.We offer our customers competitive pricing, quick processing time and an excellent customer service experience. Here, you can see how we can produce plastic products with unique characteristics through a variety of different types of molds. Contact us quickly to see how we can help you meet your plastic molding needs and experience the differences between Longsheng products.

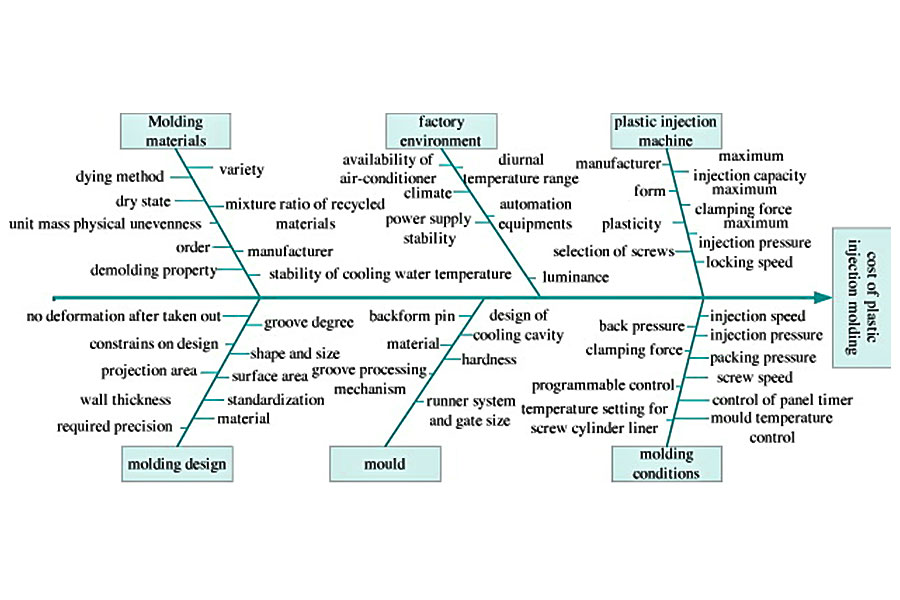

What factors affect the cost of injection molding in China?

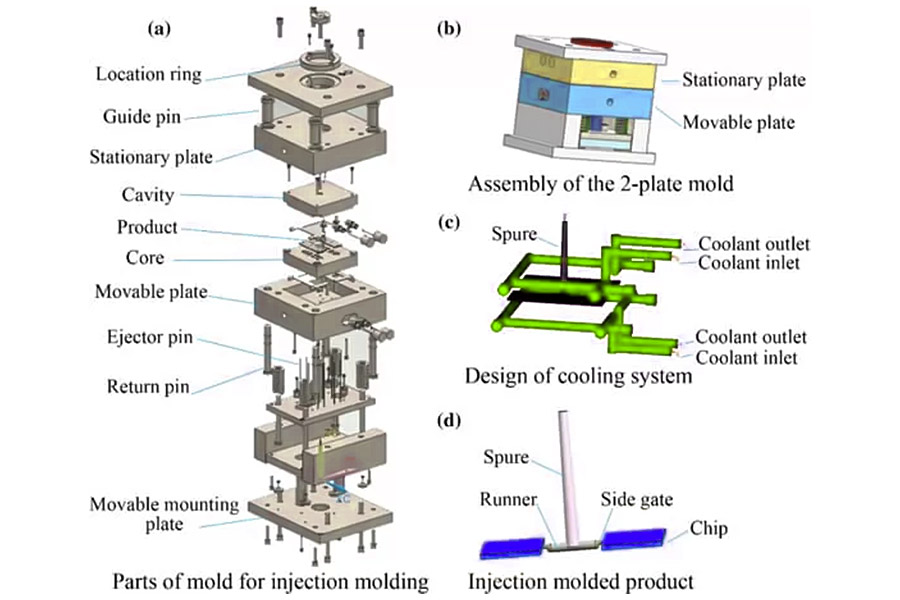

Mould design

Mold design plays a crucial role in the final cost of the injection molding project. Mold can be simple or complex, the more complex, the more expensive the mold. For example, a mold with multiple types of chambers costs more than a single cavity mold.

Mold materials

Materials used for molding also have an impact on the cost. Different types of plastics have different costs, and some materials are better than others for some uses. Material selection determines the required stiffness, durability, and heat resistance of the components.

Part size and complexity

In general, smaller and less complex parts are cheaper to produce for larger and more complex parts. The amount of the cavity in the mold also affects the cost- -the larger the cavity means that more parts can be made in each molding cycle, which reduces the cost of each part.

Material Selection

The material used for molding will impact the cost as well. Different types of plastics have different costs, and some materials are better suited for certain applications than others. Material selection will depend on factors such as the part’s required stiffness, durability, and heat resistance.

Production Volume

As I said earlier, the larger the production, the smaller the cost. But balancing production and demand is important for ── Manufacturing more than required components with unnecessary costs.

Labor Costs

The complexity of the components and the level of skill the workers require can determine labor costs. So know how to reduce labor costs and increase productivity. It is worth noting that labor costs can vary far from using custom injection molding.

Shipping And Overhead Expenses

The additional costs we have to consider include transportation and administrative costs, such as electricity, rent, insurance, etc.

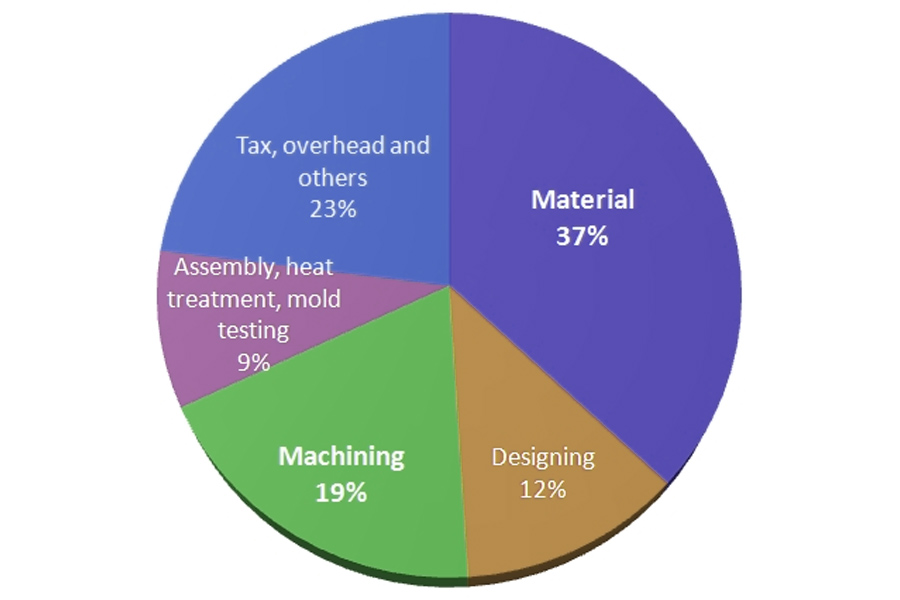

Injection molding cost composition

This section introduces the various costs of injection molding synthesis. We will deeply explore all aspects of the cost of injection molding, including what these factors will affect your business, and what measures you can take to reduce the costs.Then let us have a deep understanding of the cost of injection molding this world!

When it comes to injection molding, you need to follow several types of costs. The main costs are listed as follows:

1.Cost of materials

The cost of the raw materials used in the injection molding process is one of the most critical factors affecting the total cost of injection molding. The price of the materials may vary depending on the quality, size, and quantity ordered.

2.Labor costs

The cost of providing labor during the injection molding process is another key factor affecting the total cost. Labor costs include wages for maintenance personnel, machine operators, and other employees in the plant.

3.Energy costs

The energy cost used for injection molding is also an important factor affecting the overall cost. Energy costs may vary by the type of production process, temperature control settings, and other factors.

4.Equipment costs

The cost of purchasing and maintaining the injection molding equipment is another important cost factor.

5.Mold cost

The cost of designing, developing, and manufacturing injection molding moulds is another important cost factor.

6.Administrative expenses

Administrative expenses include all costs not directly related to the injection molding process. These expenses include rent, insurance, taxes, and other expenses.

Injection molding cost reduction ideas

1.Reducing Material Costs

You can reduce material costs by sourcing materials directly from suppliers or ordering in bulk. Properly selecting material can also help reduce wastage, which can lead to significant cost savings.

2.Automating Processes

Many injection molding processes can be automated to reduce labor costs. Investing in automation can help reduce labor costs while also improving efficiency.

3.Efficient Energy Use

Conserving energy and optimizing the use of machines can help significantly reduce energy costs.

4.Regular Maintenance

Proper maintenance of machines can help reduce downtime and the need for expensive repairs. This can greatly reduce equipment costs.

5.Improving Quality

Improving product quality can reduce wastage and reduce the need for costly reworking.

How Injection Molding Cost Calculators Work

The injection molding cost calculator is an online computing tool that allows you to accurately estimate injection molding costs. They can take into account various factors affecting the cost of injection molding. Some calculators require additional information, such as mold design, runner systems, and cycle times, to provide a more accurate estimate.

Once you enter the information you need, the calculator produces a price estimate. Estimates may include mold cost, material cost, and production cost per component. Some calculators also provide a breakdown of the costs for each component. The results of the calculator will cause you to think about how much your injection molding project will cost, and how much you can make the best choices on your budget.

How to choose a good service provider?

Professional competency assessment

Understand the professional ability and experience of service providers in the field of injection molding, including the product types, materials, processes and other they are good at.Investigate the r & d and development capabilities and technological innovation capabilities of service providers, which can be achieved by reviewing their technology patents, r & d results and cases.

Production capacity investigation

Understand the production scale, equipment configuration, and line automation to ensure they can meet your production needs. Ask the service provider about production cycles and delivery times to ensure they can deliver on time.

Quality control system

Understand the quality management system and certification of service providers, such as ISO 9001, to ensure that they have perfect quality assurance capabilities. Ask the service provider about the quality testing methods and standards, as well as their defective product processing procedures, to ensure that the product quality meets your requirements.

Service and support

Understand the pre-sales and after-sales service support of service providers, including technical support, training, maintenance, etc. Investigate the response speed and problem-solving ability of the service provider to ensure timely and effective support in the cooperation process.

Cost and price

Ask service providers for quotes and cost structure to see if their prices are reasonable. When comparing prices, do not just pursue the lowest price, but to consider the comprehensive cost performance, including product quality, delivery time, service support, etc.

Sustainability

Understand the environmental policies and sustainability practices and ensure that their production process complies with environmental regulations.

Investigate the measures and results of service providers in resource conservation, energy utilization and waste treatment.

Word of mouth and credibility

To understand the service provider’s reputation and reputation in the industry, we can obtain relevant information by consulting customer reviews, industry reports, media reports, etc. If possible, you can visit the service provider’s production site and management situation, so that you can have a more intuitive understanding of their strength and level.

Successful cases of injection molding projects in China

There are countless successful cases of domestic injection molding projects.

| Manufacturing field | clarify |

| In the field of automobile parts manufacturing | A major automotive company partnered with a Chinese company that provides injection molding services to develop complex, high-precision parts. The project stands out for its efficient production schedule and uncompromising quality benchmarks. |

| In the field of consumer electronic parts manufacturing | A global electronics brand uses injection molding services in China to produce complex parts. The large-scale project is used to produce smartphones and other consumer electronics components, so even if the order volume is large, the quality will not be compromised. |

| In the field of medical device manufacturing | A medical device manufacturer partners with a Chinese injection molding company to produce critical components. The project determines that precision and quality as well as stringent health and safety regulations are met; it emphasizes their importance to the medical field and end-users. |

Injection molding cost example

Low yield

Low-volume production can be thought of as anywhere from a hundred to a few thousand parts for any product. For these low-volume applications, manufacturers often produce the molds in-house and form the molds themselves. for

For low-volume production, manufacturers use 3D printing polymer resin to make molds because it is cheap and does not require long production cycles. The entire production process takes approximately 3 days to produce finished parts. For a 100-part run, we assume the following parameters:

- Number of parts = 1,00

- Mold cost = $1,00

- Raw material cost per part = $0.50

- Total cost of materials = $50

- Labor cost per part = $4

- Total Labour costs = $4,00

- Total cost of the injection procedure = $550

- Cost per component = $5.50

Medium volume production

Medium volume production ranges from five thousand to tens of thousands of parts. For this scale of production, manufacturers typically outsource mold production and molding processes.

For medium volume, we assume a unit production cycle of 6,000 units for the same part.

- Number of parts = 6,000

- Mold cost = $2,000

- Cost of material per part = $0.6

- Total material cost = US $3,600

- Labor cost per part = $2

- Total Labour costs = $12,000

- Total cost of injection molding = $17,600

- Cost per component = $2.93

Mass production

High-volume production involves hundreds of thousands of parts. For comparison, let’s assume we produce 100,000 parts of the same type.

- Number of parts = 100,000

- Mold cost = $25,000

- Cost of material per part = $0.50

- Total cost of materials = $50,000

- Labor cost per part = $1

- Total labor costs = $100,000

- Total cost of injection molding = $175,000

- Cost per component = $1.75

It can be seen that the injection molding cost per part is significantly lower in high-volume production. Therefore, high-volume projects are the most cost-effective projects for injection molding.

The reason for choosing Longsheng

At Longsheng, whether you need prototype parts manufacturing or mass production, we have the corresponding capabilities and experience to meet your needs. We are committed to providing reliable, quality parts to assist you with success in the competitive automotive market.

Rapid quotation

Just upload the CAD file, you can quickly understand the manufacturing cost and keep abreast of the order status.

Quick molding

Longsheng has extensive experience in prototype manufacturing, ensuring that your components are completed with high quality in the later stages of the design and manufacturing process.

ISO attestation

Longsheng is a ISO 9001 certified manufacturing company, which means that we employ internationally recognized best practices to develop your products and ensure that they meet the standards, regardless of the complexity of the design.

Customized on demand

Our auto parts manufacturing process is fully customizable according to your specifications, sizes, materials and surface requirements to ensure meeting your unique needs.

Express delivery

We are committed to providing, fast manufacturing and delivery to meet your production needs while providing you with greater flexibility to quickly respond quickly to market changes. Longsheng is a partner of your auto parts needs.

Conclusion

Although the initial cost of injection molding is high, a certain number of injection pieces are indeed cheaper than the finished pieces. Depending on the part, this crossover can range from as few as 100 parts to about 5,000 parts. Fully understanding the cost of plastic injection molding will help your project go smoothly. Hopefully all this information will help you understand the plastic injection molding cost of the project.

Longsheng focuses on the field of injection molding, from design to production to implement strict process management, to provide customers with high-quality injection molding parts.Visit our Instant Quote Engine to get a free, no-obligation quote in minutes.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

Which country has the lowest injection molding cost?

China. With China’s mature plastic raw material market, large production scale and numerous suppliers, it has formed a relatively complete industrial chain. China is rich in labor resources and has relatively low labor costs. There are many injection molding enterprises in China, many of which have large production scale. The Chinese government has been encouraging the development of the manufacturing industry, and China’s industrial chain is constantly improving.

How can Longsheng ensure the low cost and high quality?

Longsheng purchases materials directly from suppliers or orders them in batches to reduce material costs, and Longsheng’s injection molding process can be automated to reduce labor costs. The quality testing process of Longsheng company is very perfect. In Longsheng, we have a complete quality management system, and we have obtained the ISO 9001:2015 certification.

How to establish a good cooperative relationship with the injection molding company?

A good cooperative relationship requires the joint efforts of both parties. Firstly, maintain close communication and timely solve problems in cooperation; secondly, mutual trust, mutual respect and contract terms and commitments; moreover, establish regular cooperation evaluation and feedback mechanism to establish stable and mutually beneficial cooperative relationship through long-term cooperation and accumulation.

How to solve the cost increase caused by equipment inefficiency?

Equipment inefficiency may lead to longer production cycles and increased costs. In order to improve the efficiency of the equipment, the equipment can be maintained and maintained regularly to ensure that the equipment is in the best condition. At the same time, operators should be trained to improve operation skills and equipment use efficiency. Introduce the advanced equipment management system to monitor the equipment operation status and optimize it.

Resource

Cost estimation of plastic injection parts by combining PSO and BP neural network