In any production process, material selection is key not only to making a suitable and durable product, but also to ensuring successful manufacturing. Additionally, material costs have the greatest impact on the final cost of a product. Beautiful, 3D printing is versatile, thanks to the variety of materials and technologies available. However, this availability comes at a price, and the cost can be quite high.

Polycarbonate (PC) is a high-strength material suitable for Taylor environmental and engineering applications. It has extremely high heat and impact resistance. Polycarbonate also has a glass transition temperature as high as 150°C. This means focusing on maintaining its differential structure at that temperature, making it suitable for high-temperature applications. It can also bend without breaking and is typically used in applications that require some flexibility. In this article, let us explore what aspects of polycarbonate (PC) have become the ultimate choice of 3D printing materials due to its excellent performance and characteristics. What are the reasons for these properties in batch 3D printing materials?

What Is Polycarbonate 3D Printing?

Polycarbonate 3D printing is a manufacturing process that utilizes polycarbonate (PC) material to create three-dimensional objects through additive manufacturing technology (layer-by-layer). The main 3D printing technology used to create objects made of this material is called fused deposition modeling (FDM). It uses polycarbonate filament as the raw material to build up the desired shape.

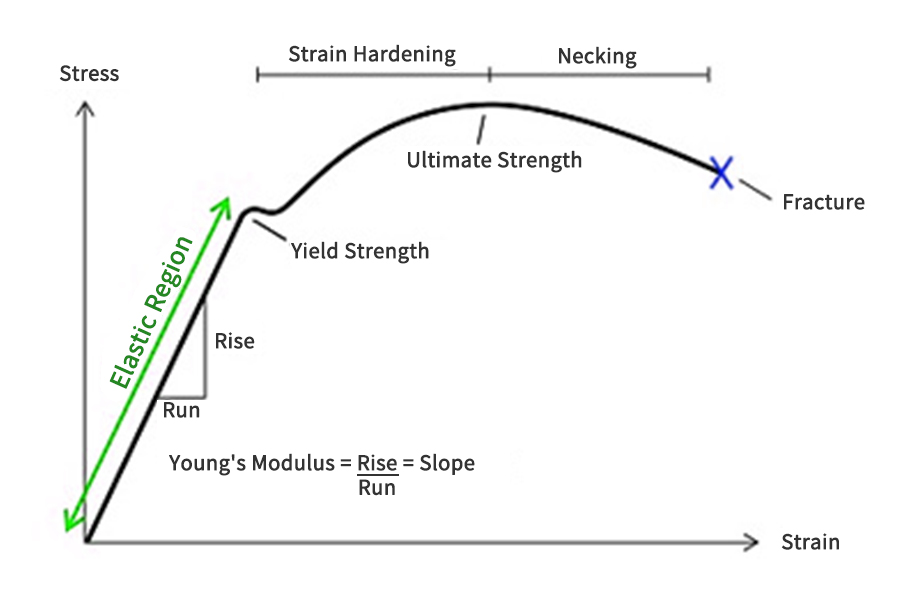

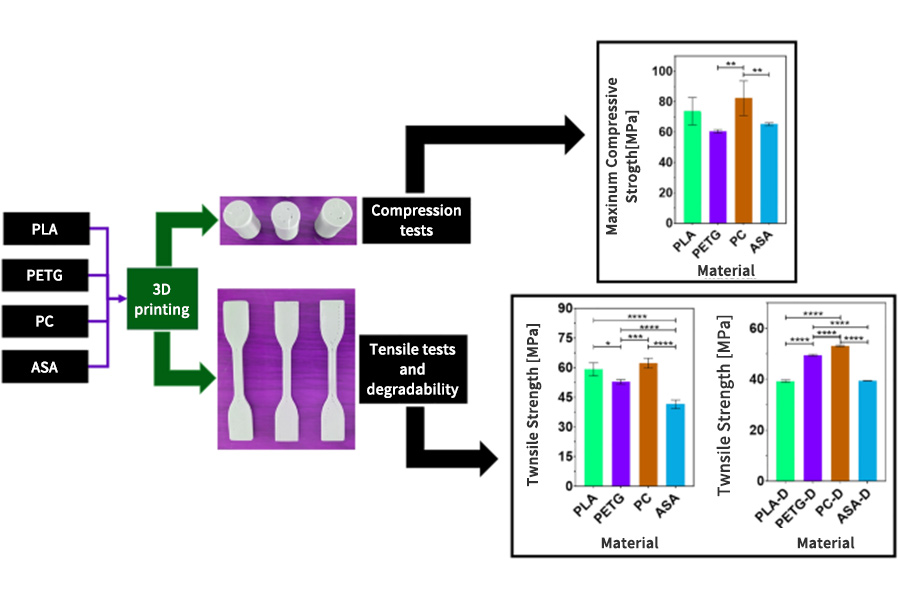

Polycarbonate (PC) boasts remarkable attributes—it’s robust, with an ultimate tensile strength of 70 MPa and yield strength of about 63 MPa, and can withstand both high heat and impacts, maintaining structural integrity even at temperatures up to 150 °C (its glass transition temperature). Owing to these properties, PC has found extensive utility in a myriad of industries such as: aerospace, automotive, electronics, medical devices, and consumer goods.

What are the advantages of polycarbonate?

- Transparency: The transparency of PC is very high, and its light transmittance is also excellent. It is often used in applications that require high optical clarity, such as eyeglass lenses and transparent protective shields.

- Impact Resistance: A notable property of this material is its excellent impact resistance. This characteristic makes it resistant to impacts in various harsh environments. It is extremely stable and is particularly suitable for applications where safety and durability are critical, such as bulletproof glass, safety goggles and car headlight lenses.

- Heat resistance: PC can withstand extremely high temperatures without melting or deforming. This device has a high glass transition temperature and is particularly suitable for applications that require working in high temperature environments, such as microwave oven-safe cookware and LED lampshades.

- Lightweight: Although this material is very strong, it is relatively lightweight. Due to its light weight, lightweight design can be carried out without changing the original structural size and shape. Therefore, this technology is widely used to reduce weight in various industries such as aviation, aerospace, and automobiles.

- UV Resistance: PC exhibits excellent resistance to ultraviolet (UV) radiation, an application that might involve panels in greenhouses or protective covers for outdoor equipment.

- Electrical insulation: It is an excellent electrical insulator that is often used in electronic and electrical components to avoid short circuits and potential electrical risks.

What are the disadvantages of polycarbonate?

- Flammability: This material has limited resistance to high temperatures and is not flame retardant itself. Additives may be used to meet specific fire safety standards.

- Chemical Sensitivity: PC is sensitive to certain chemicals, solvents, and cleaners. It is important to choose the appropriate cleaning materials and avoid exposure to incompatible chemicals.

- Cost: PC is more expensive than some other plastics.

- Not suitable for contact with food: Some types of PA may not be suitable for direct food contact due to concerns about possible leachability of bisphenol A (BPA). However, there are also BPA-free polycarbonate options available.

What Makes Polycarbonate the Ultimate Choice for 3D Printing Durability?

Polycarbonate (PC) has become the ultimate choice for 3D printing durability, mainly due to its many excellent properties and characteristics, which make it stand out among many 3D printing materials.

1.High impact resistance

Polycarbonate exhibits extremely excellent mechanical properties. Its exceptional strength and durability make it the first choice for items that have endured heavy damage. With the help of extremely high impact resistance and natural bending, PC components maintain their original shape without deformation or breakage, which allows them to adapt to and cope with a variety of harsh application scenarios. In contrast, other transparent thermoplastics (such as PMMA) are prone to cracking and breaking due to bending. In this case, polycarbonate is seen as the best option for making functional prototypes, especially where transparency and non-conductivity need to be maintained.

2.temperature adaptability

Polycarbonate stands out for its excellent high temperature resistance. This design has the ability to maintain shape deformation under high temperature conditions and is particularly suitable for the production of components that will face high temperature exposure.

3.Optical transparency

Due to its excellent transparency and light transmission, polycarbonate has many special uses when designing high-quality, visually stunning transparent or translucent materials. Compared with PETG with the same transparency, PC shows better ability to withstand impact and high temperature.

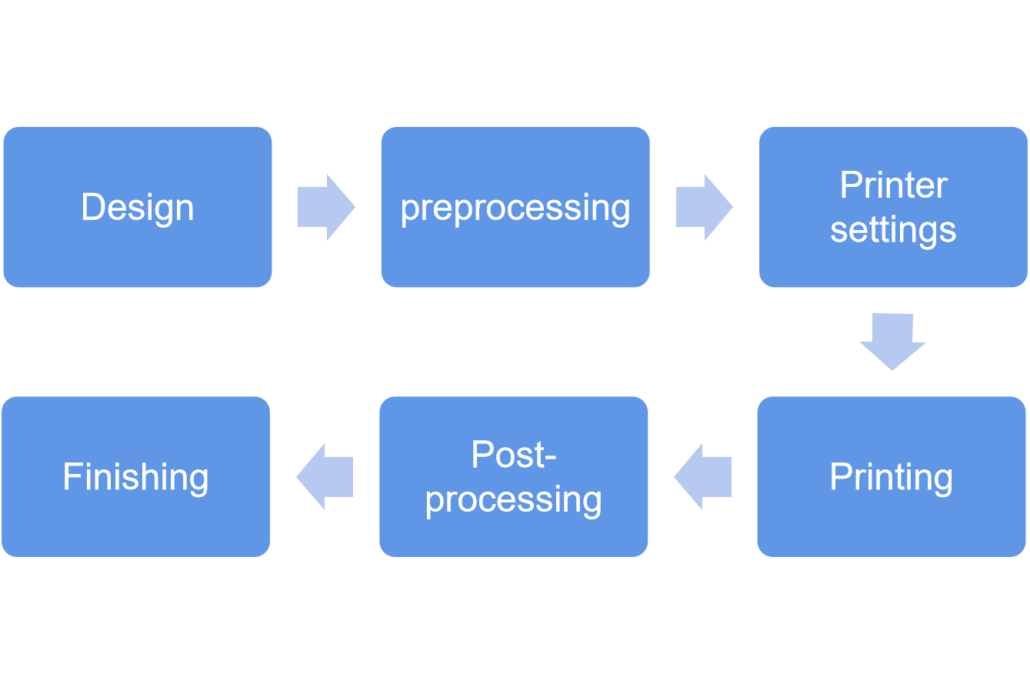

What is the step-by-step process for 3D printing polycarbonate?

1.Design

In this process, computer-aided design (CAD) software is first used to build a digital 3D model of the desired object. This model is used as a blueprint for the subsequent printing process and defines the shape, size and internal structure of the object. Then use slicing software to divide the 3D model into thin horizontal layers. Develop specific specifications for each layer. This includes the path the printer nozzle should follow to ensure precise deposition of material.

2.preprocessing

After the design is completed, the 3D model can be printed. This includes work on scaling, orientation, and positioning the model within the constructed volume. Additionally, support structures can be created to provide stability between overhangs and complex features when printing.

3.Printer settings

The 3D printer must be calibrated and prepared before printing. It involves a series of basic links to ensure optimal printing conditions. It is critical to confirm the completeness of the printing bed. This step is especially important when using materials that are sensitive to bed adhesion, such as polycarbonate. Polycarbonate is prone to warping during the printing process, which can cause consistent layer adhesion.

In addition to bed leveling, it is also crucial to ensure that the nozzle is clean and free of residues that may affect the extrusion process. Proper nozzle maintenance is key to accurate, high-quality printing. In addition, choosing appropriate printing parameters is key. Especially with polycarbonate, accurate temperature settings are critical in the extruder and build chamber. Polycarbonate has a relatively high glass transition temperature and requires careful temperature management to prevent warping and ensure proper layer bonding.

4.Printing

The actual printing process begins with the 3D printer’s extruder or nozzle heating polycarbonate filament to its melting point. The nozzle then moves to the print position defined by the machine instructions, depositing the molten material onto the print bed, layer by layer. As each layer is deposited, the molten polycarbonate merges with the previously deposited layer, forming a strong bond between them. This layer-by-layer approach leads to the step-by-step construction of the final object.

After all layers are printed, the object will completely cool and solidify. Depending on the complexity and size of the print, this may take varying amounts of time. To maintain ideal printing conditions, other mechanisms can be employed to regulate temperature, including the use of fans or heated build chambers.

5.Post-processing

Once printing and cooling are complete, the object is removed from the build plate. Post-processing may involve removing excess support material, cleaning parts, and addressing any imperfections on the surface. This depends on the complexity of the design and the presence of supporting structures.

6.Finishing

To achieve the desired appearance and functionality, finishing steps may be required. This may include sanding smooth surfaces, painting or coating to enhance aesthetics, and adding any required assembly parts.

Comparison of Polycarbonate 3D Printing with Other 3D Printing Technologies

| Polycarbonate 3D Printing | Other 3D Printing Technologies |

|---|---|

| Polycarbonate 3D printing utilizes polycarbonate as the raw material. It is commonly performed using the fused deposition modeling (FDM) method, where the polycarbonate filament is melted and layered to create three-dimensional objects. | Other 3D printing technologies encompass a wider range of materials and techniques, including digital light processing (DLP), selective laser melting (SLM), electron beam melting (EBM), material jetting, binder jetting, stereolithography (SLA), and selective laser sintering (SLS). |

| Polycarbonate printing offers isotropic properties, providing consistent mechanical characteristics in all directions due to the layered structure. | Other 3D printing methods may result in anisotropic properties, where the material’s characteristics can vary along different axes of the object, depending on the technique used. |

| Polycarbonate 3D printing allows for rapid prototyping and customization, making it ideal for low volume production runs and tailored designs. | Traditional 3D printing methods often require molds and tooling, limiting customization and cost-effectiveness for small runs. |

Comparison of polycarbonate and PLA printing materials

PLA (polylactic acid) is a thermoplastic made from organic materials such as corn, sugar cane, and other plant matter. It is one of the most popular filament options for 3D printing and is a favorite among beginners due to its low melting point and low shrinkage. This makes it easy to use since it doesn’t require a fancy hot end or even a heated print bed to print.

Stiffness

| Stiffness | PC | PLA |

| Tensile Strength | PC material has excellent tensile strength and can withstand large tensile forces without breaking easily. This high-strength property makes PC materials widely used in many fields, such as electronics and electrical, automobile manufacturing, etc. | The tensile strength of PLA is lower than that of PC. Although it does have some strength, it is not typically used in applications that require it to withstand high tensile loads. |

| Yield Strength | Yield strength is an assessment of the ability of a material to begin plastic deformation when subjected to external forces. PC material has excellent yield strength and can withstand large forces without plastic deformation. | PLA has a relatively low yield strength, so it is more prone to plastic deformation when subjected to external forces. |

| Impact Strength | PC material has excellent impact resistance and can maintain structural integrity when impacted and is not easy to break. | PLA has lower impact strength compared to PC. Although it also has some impact resistance, it is more susceptible to damage when subjected to strong impacts. |

| Other | PC materials also have excellent rigidity and hardness, and these properties are closely related to strength. PC has high hardness and is resistant to scratches and wear. | PLA has relatively low rigidity and hardness, but its degradability and environmental friendliness give it unique advantages in certain applications. |

How to choose between polycarbonate and PLA?

- Strength Requirements:If your parts need to withstand high strength, high impact or high pressure, then PC is a better choice. PC’s high strength and rigidity allow it to withstand these stresses, and its chemical and abrasion resistance also allow it to perform well in harsh environmental conditions.

- Cost Matters:If price is your main consideration, PLA may be a better choice. PLA generally has lower material costs than PC and is easier to print, which means you may not need to invest as much time and resources in adjusting print settings or troubleshooting print problems.

- Printing Technology:If you are new to 3D printing or don’t have much printing experience, PLA may be a better choice. PLA is simpler to print and typically does not require a heated bed or special print setup, making it a good choice for beginners.

- Application Scenarios:Finally, you need to choose the most appropriate material based on the specific use of the part. If the part must be used in harsh environmental conditions, or needs to withstand high pressure or friction, PC may be a better choice. If the part is intended primarily for education, art, and decoration, or if rapid prototyping is required, PLA may be a better choice.

Polycarbonate compared to other 3D printing materials

The unique properties and superior performance of this material become even more apparent when we compare PC to other plastics used in 3D printing.

- ABS (Acrylonitrile Butadiene Styrene): ABS is another widely used 3D printing material that offers good impact resistance and durability. However, PC’s strength, heat resistance, and toughness exceed ABS. Polycarbonate has an excellent heat distortion temperature, which means it can handle high-temperature applications where ABS may warp.

- Nylon (Polyamide): Nylon is widely recognized for its strength and flexibility comparable to PC. However, polycarbonate is superior at making printed parts rigid and isotropic. Nylon readily absorbs moisture from the air, which affects its strength and dimensional stability. In comparison, PC is less hygroscopic and has better dimensional stability.

- PETG (polyethylene terephthalate): PETG combines the ease of printing of PLA with the strength of ABS. But overall, PC performance is superior. While PETG offers decent durability, heat resistance, and flexibility, polycarbonate outperforms in these properties. PC has higher impact resistance and heat deflection temperature, making it a stronger material for demanding applications.

All in all, while each plastic material has its benefits and applicable uses, PC’s superior durability, toughness, and rigidity make it suitable for 3D printing.

| Filament | Strong Points | Uses | Difficulty to use | Print Temperature | Bed Temperature | Shrinkage / Warping | Food Safe |

|---|---|---|---|---|---|---|---|

| 1. PLA | Easy to printBiodegradableVariety of colors available | Decorative and non-durable item | Low | 180°C –230°C | 20°C – 60°C (optional) | Minimal | No |

| 2. ABS | DurableResistant to high temperaturesImpact-resistant | Items requiring strength, durability, and resistance to heat | Medium | 210°C –250°C | 80°C – 110°C | High | No |

| 3. PETG | DurableEasy to printFlexibleResistant to high temperature and impact | Functional objects | Low | 220°C –250°C | 50°C – 75°C | Minimal | Yes, as long as there are no harmful additives |

| 4. TPE | Rubber-likeStretchable and softDurable | High-wear objects or items that need to be bent, stretched, or compressed | Medium | 210°C –230°C | 30°C – 60°C (optional) | Minimal | No |

| 5. Nylon | DurableFlexibleHigh impact resistanceHeat resistant | Functional prototypes, gears, mechanical parts, and aesthetic objects | Medium | 240°C –260°C | 70°C – 100°C | High | See manufacturer guidelines |

| 6. PC | DurableHeat and impact resistant | High-wear items such as automotive, electrical, and mechanical parts | Medium | 270°C –310°C | 90°C – 110°C | High | No |

| 7. ASA | Heat and UV resistantHigh impact and wear resistanceNo yellowing or discoloration vs ABS | Outdoor objects, sports equipment, electrical installations | High | 220°C –245°C | 90°C – 110°C | High | Yes, depending on the grade of the material |

How Much Does Polycarbonate 3D Printing Cost?

The cost of 3D printing polycarbonate is affected by a variety of factors, which causes its cost to fluctuate widely. Production costs can be controlled by changing raw materials and processes in cost analysis. The printed filament forms a critical part of the total cost. Polycarbonate wire offers excellent performance and unique structure. Compared with other 3D printing materials, polycarbonate filaments are more expensive. Due to its high cost, the application of polycarbonate is limited. The estimated cost of each roll of PC cable is between $30-60. The cost mainly consists of three parts: production cost, labor and consumables. Labor costs cover many aspects such as printer configuration, post-processing, and fault diagnosis. These tasks need to be completed on the production line. Other costs come from software, design tools, and delicate processes like sanding, spraying, or painting.

Given all of these considerations, determining the exact cost of polycarbonate 3D printing is a challenging task in the absence of specific project details. If the technology can be accurately costed, a reasonable price can be set for it. When conducting a comprehensive cost assessment, we must consider printer maintenance, energy consumption, manual operations, and other ancillary processes.

What Are The Applications Of Polycarbonate?

Polycarbonate’s exceptional durability, toughness and stiffness make it a versatile choice for a wide range of applications in different industries. It performs well in challenging conditions and enables high-value use in a wide range of areas.

- Mechanical components: High impact resistance and strength make it an excellent choice for producing strong mechanical components. These components may include gears, fasteners, and other moving parts within machinery where durability under repeated stress is critical.

- Automotive Applications: In the automotive industry, it can be used to produce parts that require high heat resistance and impact strength. These parts may include light covers, fenders, bumpers and other parts that need to withstand the heat and stress common in vehicle operation.

- Protective Gear: PC’s toughness and flexibility make it an excellent choice for protective gear such as helmets, goggles, or shields.

- Electronic Enclosures: Due to its good electrical insulation properties, durability and heat resistance, it is ideally suited for use in electronic enclosures. It protects delicate internal components while withstanding the heat generated by these electronic devices.

- Medical Devices: In the medical field, it is used to make durable components such as surgical instruments, drug delivery devices, and diagnostic equipment. Its ability to sterilize without losing its performance makes it valuable in this industry.

- Building and construction applications: It can be used to build structural components such as windows, skylights or partitions. Its strength makes it ideal for these applications.

What are the precautions for using polycarbonate 3D printing?

- Extrusion temperature: The recommended extrusion temperature for PC 3D printing is 260° to 290° C (sometimes, some filaments can even reach 320° C)

- Bed Temperature: A heated bed or heated build plate needs to reach a minimum temperature of at least 110°C. The ideal temperature is 135°C. The pre-drying process should be carried out for 2 to 12 hours so that the material obtains a moisture content not exceeding 0.02%. Polycarbonate printing temperatures can cause warping. Therefore, good gluing of the boards is highly recommended. Also, it is highly recommended to apply additional solution to the tray to make the first layer more sticky.

- Printing speed: PC 3D printing requires a printing speed of approximately 10-80 mm/s.

- Heating Chamber: The temperature of the polycarbonate filament should remain stable. A closed chamber is necessary because temperature fluctuations can cause the product to crack or deform. Heat-drying materials are not allowed to be placed in cool open air environments.

- Storage conditions: You should store it in a dry, resealable bag or container to avoid moisture and contamination. If the bag is opened, make sure it can be resealable for further storage.

- 3D printer configuration: 3D printing polycarbonate materials will vary depending on PC brands and models, so the 3D printer configuration and processing parameters may need to be changed. Operators need to always pay attention to the printing parameters recommended by the material manufacturer.

What products are 3D printed with polycarbonate?

- Custom bulletproof glasses

- Prototype for tailor-made diving mask

- Prototype electronic display housing

- Personalized goggles for specific needs

- Custom optics for research

- Uniquely designed motorcycle helmet prototype

- Special protective screens for special applications

- Custom electrical and telecommunications prototypes

- Custom sunglass frames or phone cases

Challenges of 3D printing polycarbonate

While polycarbonate 3D printing offers many advantages, it also comes with challenges. Depending on your setup, PC can be tricky to print because it requires high temperatures, is sensitive to cooling, is highly hygroscopic, and has adhesion issues.

The printing temperature is high. Standard 3D printers are not always able to achieve the required processing temperatures of over 300°C. Most printers also have trouble keeping the heated bed temperature at the correct level. Additionally, an all-metal hot end is required to effectively 3D print with polycarbonate. So if you have a standard 3D printer, you may need to make some modifications.

Warping problem. PC is highly susceptible to warping compared to ABS, so precise print settings are required to avoid this.

Hygroscopic. When exposed to air, polycarbonate absorbs large amounts of moisture from the air, reducing its 3D printing properties. PC-based filaments must always remain in a closed, dry state.

Sensitivity to UV rays and hydrolysis. Polycarbonate degrades in sunlight and is poorly reactive with water, making it unsuitable for any outdoor applications.

What are the challenges of polycarbonate 3D printing?

While polycarbonate 3D printing offers many advantages, it also comes with challenges. Depending on your setup, PC printing can be complicated because it requires high temperatures, is sensitive to cooling, is highly hygroscopic, and has adhesion issues. Standard 3D printers are not always able to achieve the required processing temperatures of over 300°C. Most printers also have trouble keeping the heated bed temperature at the correct level. Additionally, an all-metal hot end is required to effectively 3D print with polycarbonate. So if you have a standard 3D printer, you may need to make some modifications. PC is highly susceptible to warping compared to ABS, so precise print settings are required to avoid this. When exposed to air, polycarbonate absorbs large amounts of moisture from the air, reducing its 3D printing properties. PC-based filaments must always remain in a closed, dry state. Sensitivity to UV rays and hydrolysis. Polycarbonate degrades in sunlight and is poorly reactive with water, making it unsuitable for any outdoor applications.

Future developments and trends in polycarbonate 3D printing

The future development and trends of polycarbonate (PC) in the field of 3D printing show broad prospects and huge potential. Because polycarbonate has excellent mechanical properties and thermal stability, researchers are exploring ways to optimize the printing process to obtain better results. Improved nozzle designs, advanced temperature control systems and enhanced filament compositions may be available, allowing for a smoother printing experience and higher quality output.Additionally, as demand for sustainable and environmentally friendly manufacturing processes continues to grow, we can foresee the development of recycled polycarbonate filaments and biodegradable additives.

These innovations not only reduce environmental impact but also provide more sustainable solutions across industries.Additionally, the rise of Industry 4.0 and the Internet of Things (IoT) is expected to drive the integration of polycarbonate 3D printing into smart manufacturing systems. Automated printing processes, remote monitoring capabilities and data-driven optimization will revolutionize the way polycarbonate components are produced, increasing efficiency and productivity.In the coming years, we may see polycarbonate 3D printing expand into new areas and applications. From personalized medical devices to customized consumer products, polycarbonate’s versatility and adaptability will continue to drive innovation and creativity across a variety of industries.Overall, the future of polycarbonate 3D printing is bright, bringing exciting opportunities for manufacturers, designers, and consumers. By embracing cutting-edge technology and pushing the boundaries of what is possible, we can expect to see significant advancements in additive manufacturing of polycarbonate materials.

Why choose Longsheng’s online 3D printing service?

- Multi-material processing: We have the ability to process a variety of materials, no matter what material parts you need to process, we can provide professional solutions.

- Competitive prices: We provide competitive prices and cost-effective solutions to ensure customers gain the greatest advantage in cost control.

- Customized Services: Provide customized solutions based on customers’ design requirements and specifications to ensure parts meet their unique needs.

- Fast delivery: We have efficient production processes and flexible production plans, allowing us to deliver customer orders in a timely manner and meet urgent project needs.

Summary

What makes polycarbonate the ultimate choice for 3D printing durability is its excellent physical properties, chemical stability, and broad application adaptability. These properties allow polycarbonate to play an excellent role in various fields and meet the needs of various complex and demanding applications. At the same time, with the continuous development and maturity of 3D printing technology, the application prospects of polycarbonate in the field of 3D printing will be broader.Visit our Instant Quote Engine to get a free, no-obligation quote in minutes.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

Are polycarbonate 3D printed products durable?

Polycarbonate 3D printed products are indeed very durable due to their tensile strength, heat resistance, impact, impact and scratch resistance. Their ability to withstand a wide range of forces and maintain structural integrity over time makes them a reliable choice for a variety of applications.

What is the difference between polycarbonate 3D printing and 3D printing?

The main difference between polycarbonate 3D printing and regular 3D printing is the raw material used. Polycarbonate 3D printing exclusively uses polycarbonate filament, while general 3D printing covers a wider range of materials and technologies, such as metals and other thermoplastics. Each printing method offers unique advantages and applications based on the desired characteristics of the final product.

What Precautions Are Needed For Polycarbonate 3D Printing?

When choosing polycarbonate for 3D printing, you need to note that polycarbonate is a high-performance thermoplastic with excellent heat resistance, impact resistance, and transparency. Make sure the 3D printer can handle high-temperature materials, as PC has a higher melting temperature. Set the printing parameters reasonably according to the material characteristics of the PC and the performance of the printer. After printing is completed, the parts need to be handled carefully to avoid damage to the parts during the operation. Conduct quality inspections on printed parts, including dimensional accuracy, surface quality, structural strength, etc. Carry out regular maintenance and upkeep on 3D printers to ensure normal operation of the equipment and print quality.

Which Is More Difficult To Print On PC Or PLA?

From the perspective of material properties and printing parameter settings, PC printing is relatively difficult. Its high temperature characteristics and sensitivity to temperature changes require users to have higher 3D printing knowledge and experience, and to adjust printing parameters more precisely. In comparison, PLA is less difficult to print and is suitable for beginners and general users. Its lower melting point and better interlayer adhesion make the printing process more stable and reliable. Therefore, in terms of printing difficulty, PC printing is more difficult, while PLA is relatively easy.