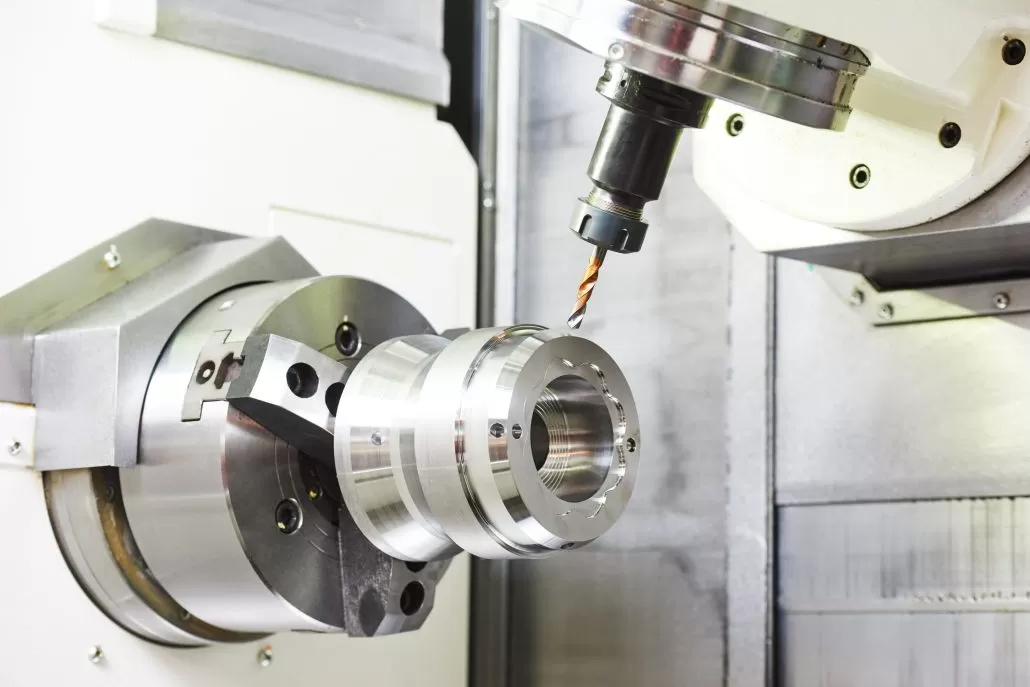

CNC machining is a form of automated machining that uses computers to control specific tools in order to shape and produce parts. This type of machining is highly precise and efficient, which makes it a popular choice for many industries. Here are some of the advantages of using CNC machining.

Increased Productivity

One of the main advantages of CNC machining is that it can increase productivity in a manufacturing plant. By automating the machining process, CNC machines can work continually, producing parts with greater speed and accuracy than manual methods. This can lead to faster production times and higher output. Additionally, CNC machines can be programmed to produce multiple copies of the same parts with little setup time, allowing for large batches of items to be produced quickly and efficiently.

Enhanced Accuracy

Another advantage of CNC machining is that it provides enhanced accuracy compared to manual machining. By relying on computer programming to guide the cutting tools, CNC machines are able to achieve extremely precise results. This means that parts can be created with tight tolerances, reducing the risk of errors and defects. CNC machining also eliminates the need to manually measure and adjust the cutting parameters, further improving accuracy.

Cost Savings

CNC machining can provide cost savings in various ways. For one, the speed and accuracy of CNC machining can enable manufacturers to produce parts more quickly, reducing the amount of time and materials required for each part. Furthermore, CNC machining can also reduce labor costs since fewer employees are needed to operate the machine. Additionally, CNC machining can eliminate the need for rework, since the machine produces parts that are accurate to the exact specifications.

Versatility

CNC machining is also quite versatile, as it can be used to create parts from a variety of different materials. This includes metals such as aluminum, brass, and steel, as well as plastics and other materials. The tooling used by CNC machines can also be changed fairly easily, allowing for parts to be machined from different materials without a lot of extra effort. Furthermore, CNC machining can be used to produce complex parts with intricate details, such as threads and grooves.

Faster Setups

In addition to increasing accuracy, CNC machines can also reduce setup times. Manual machining often requires an operator to adjust the machine parameters and make sure that they are set correctly. With CNC machining, these parameters can be programmed in advance, eliminating the need for manual adjustments. Furthermore, CNC machines can be quickly switched from one job to another, due to their ability to store cutting data in their memory. This can help to significantly reduce setup times.

Overall, CNC machining offers numerous advantages for manufacturers. It can increase productivity, reduce labor costs, and improve accuracy. Additionally, it can be used on a variety of materials, and its setup times are much shorter than those of manual machines. Therefore, CNC machining can be a great choice for companies looking to improve their manufacturing process and increase efficiency.

Related product processing customized services:

CNC Machine Parts Manufacturer

CNC Milling Parts Machining Service

High -Precision CNC Turning Machine Parts

Sheet Metal Machining Parts Center