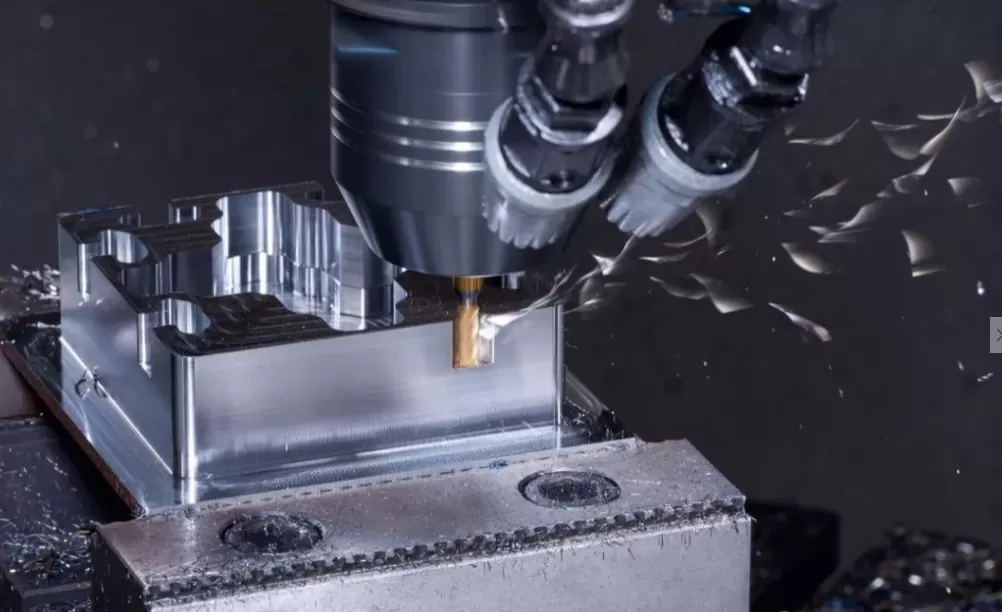

Rapid manufacturing is a process that allows for the quick production of functional prototypes, tooling, and end-use parts. One of the key technologies used in rapid manufacturing is CNC machining. In this article, we will explore the advantages of CNC machining for rapid manufacturing.

Precision

CNC machining is known for its high precision. The process is automated, which means that the chances of error are greatly reduced. CNC machines are capable of producing parts with extremely tight tolerances, which makes them ideal for rapid manufacturing. The precision of CNC machining makes it possible to create complex parts with intricate details that would be difficult or impossible to produce with other manufacturing technologies. This precision is essential for creating functional prototypes and end-use parts that meet strict performance requirements.

Speed

CNC machining is also known for its speed. Once a design has been loaded into the machine, it can produce parts quickly and efficiently. This makes CNC machining an ideal technology for rapid manufacturing, where speed is of the essence. The speed of CNC machining makes it possible to produce parts in a matter of hours or days, depending on the complexity of the part. This is a significant advantage over traditional manufacturing technologies, which can take weeks or even months to produce parts.

Versatility

CNC machining is a versatile technology that can be used to produce a wide range of parts. Whether you need a simple part or a complex one, CNC machining can handle the job. This makes it ideal for rapid manufacturing, where a wide range of parts may be required. CNC machining can be used to produce parts from a variety of materials, including metals, plastics, and composites. This versatility makes it possible to create parts with different physical and mechanical properties, depending on the application.

Cost-effective

CNC machining is a cost-effective technology for rapid manufacturing. Once the machine is set up, it can produce parts quickly and efficiently, which can help to keep costs down. This makes CNC machining an ideal technology for companies that need to produce parts quickly and cost-effectively. When compared to traditional manufacturing technologies, CNC machining can be more cost-effective for producing low to medium volume production runs.

Quality Control

CNC machining also offers a high level of quality control. CNC machines can be programmed to perform quality checks during the machining process, ensuring that parts meet the required specifications. This reduces the need for manual inspection and can help to eliminate errors that can occur during manual inspection. This makes CNC machining an ideal technology for companies that require high-quality parts that meet strict performance requirements.

Scalability

CNC machining is a scalable technology for rapid manufacturing. CNC machines can be programmed to produce large quantities of parts quickly and efficiently. This makes CNC machining ideal for companies that need to produce large volumes of parts in a short amount of time. The scalability of CNC machining makes it possible to ramp up production quickly to meet changing market demands.

Innovation

CNC machining also allows for innovation in product design. The precision and speed of CNC machining mean that designers can create parts with complex geometries and intricate details that were once impossible to produce. This opens up new possibilities for product design and can help companies to differentiate themselves in the market.

Conclusion

In conclusion, CNC machining is a key technology used in rapid manufacturing. It offers a range of advantages, including high precision, speed, versatility, and cost-effectiveness. If you need to produce parts quickly and efficiently, CNC machining is definitely worth considering. CNC machining is a reliable and efficient manufacturing technology that can help you meet your production goals and deadlines. Whether you need functional prototypes, tooling, or end-use parts, CNC machining can help you achieve your goals.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items