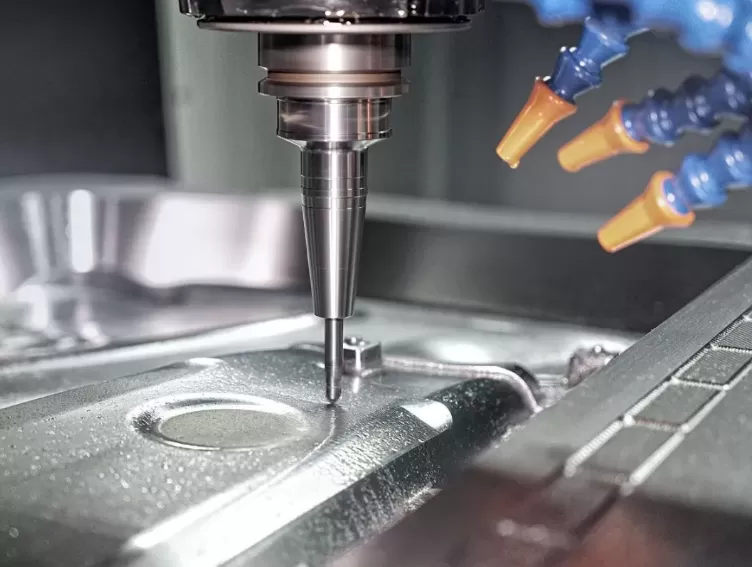

CNC machining is a process that uses computer-controlled machines to create precise and complex parts. This technology has revolutionized the manufacturing industry, and it has become an essential tool for many small businesses. In this article, we will discuss the advantages of CNC machining for small businesses.

Consistency and Precision

One of the biggest advantages of CNC machining is its consistency and precision. The machines are programmed to create parts with the same specifications every time, which eliminates the possibility of human error. This ensures that the parts are of high quality and meet the required standards.

Efficiency and Speed

CNC machines can produce parts much faster than traditional machines. They can also work continuously without the need for breaks, resulting in increased efficiency and productivity. This is especially important for small businesses that need to produce large quantities of parts quickly.

Flexibility

CNC machines can create a wide range of parts with varying levels of complexity. They can also work with a variety of materials, including metal, plastic, and wood. This makes them an ideal tool for small businesses that need to produce a variety of parts for different applications.

Cost-Effective

CNC machining can be cost-effective for small businesses in several ways. First, it eliminates the need for expensive tooling and molds, which can be a significant expense for traditional manufacturing methods. Second, it reduces the need for manual labor, which can save businesses money on wages and benefits.

Improved Safety

CNC machines are designed to operate safely and efficiently. They have built-in safety features that protect workers from accidents and injuries. This is particularly important for small businesses that may not have the resources to invest in expensive safety equipment.

In conclusion, CNC machining parts services offers several advantages for small businesses, including consistency and precision, efficiency and speed, flexibility, cost-effectiveness, and improved safety. By investing in this technology, small businesses can increase their productivity, reduce costs, and improve the quality of their products.

Competitive Advantage

Small businesses that use CNC machining have a competitive advantage over those that do not. They can produce high-quality parts quickly and efficiently, which can help them meet customer demands and beat their competitors. This can lead to increased sales and profits for the business.

Customization

CNC machining allows small businesses to create customized parts for their customers. They can design and create parts based on specific requirements, which can help them stand out in the market. This can also lead to increased customer satisfaction and loyalty, which is essential for the long-term success of any business.

Scalability

CNC machining is scalable, which means that small businesses can increase their production capacity as their business grows. They can add more machines or upgrade their existing ones to meet the increasing demands of their customers. This allows small businesses to expand their operations without incurring significant costs.

Innovation

CNC machining encourages innovation in small businesses. It allows them to experiment with new designs and materials, which can lead to the creation of new products and services. This can help small businesses stay ahead of the competition and adapt to changing market trends.

Access to Skilled Labor

CNC machining requires skilled labor to operate and maintain the machines. Small businesses that use CNC machining have access to skilled labor, which can be a challenge for traditional manufacturing methods. This can help small businesses attract and retain talent, which is essential for the growth and success of the business.

In conclusion, CNC machining offers several advantages for small businesses, including competitive advantage, customization, scalability, innovation, and access to skilled labor. By investing in this technology, small businesses can improve their operations, increase their profitability, and stay ahead of the competition.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items