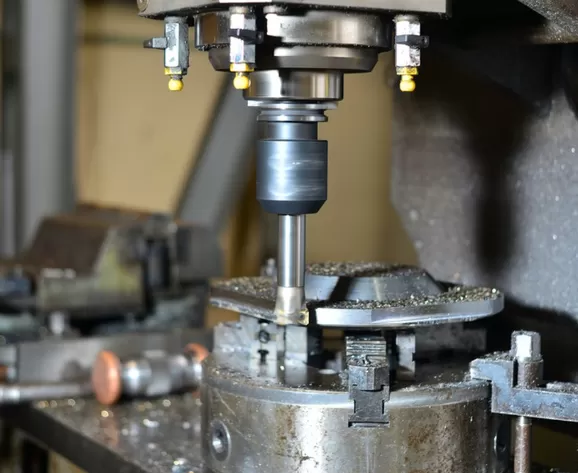

Computer Numerical Control (CNC) milling is a manufacturing process that involves the use of pre-programmed computer software to control the movement of milling machines. This technology has revolutionized the manufacturing industry by allowing for greater precision, accuracy, and speed than traditional milling techniques. In this article, we’ll explore some of the key advantages of CNC milling machine parts over traditional milling.

- Greater precision and accuracy

One of the most significant advantages of CNC milling is its ability to achieve greater precision and accuracy in the manufacturing process. CNC machines are programmed with specific instructions that dictate the movement of the cutting tool, allowing for consistent and precise cuts every time. This level of precision is difficult to achieve with traditional milling techniques, where the operator must rely on their own skill and judgment to make accurate cuts.

- Faster production times

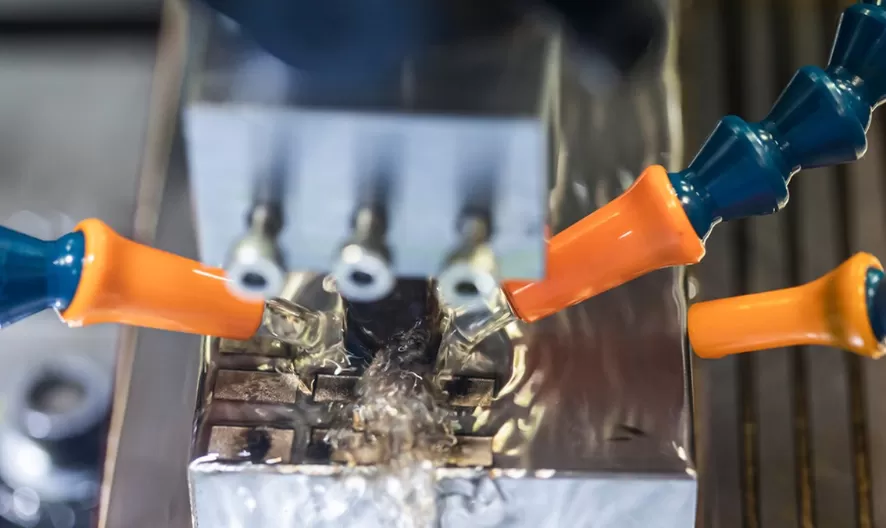

CNC milling machining parts are capable of operating at high speeds, allowing for faster production times than traditional milling techniques. Additionally, the pre-programmed software used in CNC milling allows for the automation of many of the manufacturing processes, reducing the need for manual labor and increasing productivity.

- Increased efficiency

CNC milling machines are designed to be highly efficient, with many machines capable of running 24 hours a day, seven days a week. This level of efficiency is difficult to achieve with traditional milling techniques, where the operator must take breaks and rest periods to avoid fatigue.

- Lower costs

While CNC milling machines may have a higher initial cost than traditional milling machines, they are often more cost-effective in the long run. This is because they require less manual labor and can produce parts at a faster rate, reducing labor costs and increasing production efficiency.

- Greater versatility

CNC milling machines are capable of producing a wide range of parts and components, from simple parts to complex geometries. This versatility makes them ideal for use in a variety of industries, including aerospace, automotive, and medical.

- Improved safety

CNC milling machines are designed with safety in mind, with many machines featuring automatic shut-off mechanisms and other safety features to protect operators from injury. This level of safety is difficult to achieve with traditional milling techniques, where the operator must rely on their own judgment to avoid accidents.

In conclusion, CNC milling machines offer a range of advantages over traditional milling techniques, including greater precision, faster production times, increased efficiency, lower costs, greater versatility, and improved safety. As technology continues to evolve, it’s likely that CNC milling will become even more prevalent in the manufacturing industry, allowing for faster, more efficient, and more cost-effective production of parts and components.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items