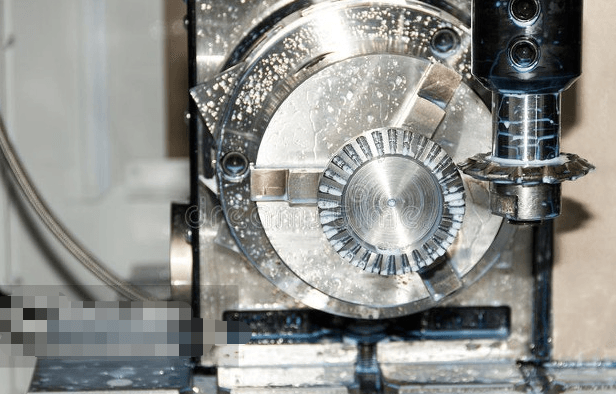

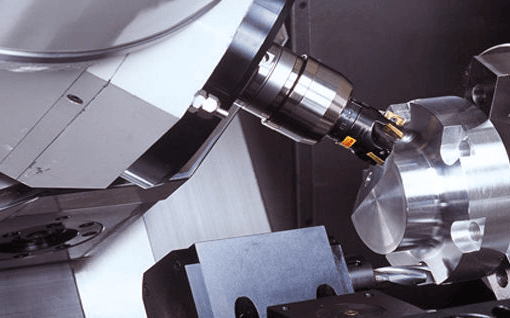

Multi-axis CNC milling machining is a manufacturing process that involves cutting, drilling, and shaping a workpiece using computer-controlled machines. This process offers a wide range of advantages over traditional milling methods, including increased efficiency, precision, and versatility. In this article, we will explore the advantages of multi-axis CNC milling machining and why it is the preferred method for producing complex and intricate parts.

Improved Efficiency and Productivity

One of the primary advantages of multi-axis CNC milling parts machining is improved efficiency and productivity. With the ability to work on multiple sides of a workpiece simultaneously, multi-axis machines can reduce the need for secondary operations and improve turnaround times. Additionally, multi-axis machines can handle complex geometries and intricate designs, reducing the need for manual intervention and improving overall efficiency.

Precision and Accuracy

Multi-axis CNC milling machining is also known for its precision and accuracy. With the ability to work on multiple axes, these machines can perform highly detailed and complex tasks with consistent quality. This precision and accuracy are essential for industries such as aerospace and medical device manufacturing, where even small errors can have significant consequences.

Versatility

Multi-axis CNC milling machining is highly versatile, making it ideal for use in a variety of industries and applications. It can work with a wide range of materials, including metals, plastics, and composites, and can produce parts with complex geometries and intricate designs. This versatility allows manufacturers to produce parts for a variety of industries and applications, making it the perfect solution for those looking to expand their business.

Reduced Costs and Waste

Multi-axis CNC milling machining has also reduced costs and waste in manufacturing. By producing parts with high precision and accuracy, multi-axis machines reduce the need for rework or redesigns, saving time and money. Additionally, multi-axis machines can reduce waste by producing parts with minimal scrap or material loss.

Automation

One of the most significant advantages of multi-axis CNC milling machining is automation. These machines can be programmed to perform a wide range of tasks, from loading and unloading workpieces to performing complex machining operations. This automation reduces the need for human intervention and can result in significant cost savings for manufacturers.

Conclusion

Multi-axis CNC milling machining offers a wide range of advantages over traditional milling methods, including increased efficiency, precision, versatility, reduced costs and waste, and automation. By staying up to date on the latest advancements in multi-axis CNC milling machining technology, manufacturers can continue to improve their processes and stay ahead of the competition.

If you’re interested in learning more about the advantages of multi-axis CNC milling machining or how to implement it in your manufacturing process, be sure to consult with experts in the field to determine the best solutions for your specific needs and requirements.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items