This article provides an overview of the best aluminum materials for CNC machining, including their properties and applications. We also answer common questions about CNC machining and aluminum parts.

If you are looking for a reliable CNC machining service provider for your aluminum parts project, consider a provider that has experience working with aluminum, uses state-of-the-art equipment and technology, and offers competitive pricing and excellent customer service.

Why Choose Aluminum Material For CNC Machining?

CNC machining is a manufacturing process that involves using computer-controlled machines to create intricate and precise parts. One of the most commonly used materials in CNC machining is aluminum. Here are some reasons why aluminum is a popular choice for CNC machining:

Lightweight

Aluminum is a lightweight material, making it ideal for applications where weight is a concern. It is about one-third the weight of steel, which means it can be used in products that require strength but also need to remain lightweight.

Corrosion-resistant

Aluminum is naturally corrosion-resistant, which means it can withstand exposure to the elements without rusting or corroding. This makes it an excellent choice for outdoor applications or products that need to withstand harsh environments.

Easy to machine

Aluminum is also easy to machine, which means it can be quickly and efficiently turned into the desired shape or size. This makes it an excellent material for CNC machining, as it can be easily shaped and cut into complex designs.

High strength-to-weight ratio

Despite its lightweight nature, aluminum has a high strength-to-weight ratio, making it a strong and durable material. It can withstand high stress and pressure without deforming or breaking, making it ideal for applications that require strength and durability.

Versatile

Aluminum is a versatile material that can be used in a wide range of applications. It can be easily anodized, painted, or coated to improve its appearance and protect it from wear and tear. It is also a good conductor of heat and electricity, making it an excellent choice for applications where heat dissipation is a concern.

In conclusion, aluminum is a popular choice for CNC machining due to its lightweight nature, corrosion resistance, ease of machining, high strength-to-weight ratio, and versatility. If you are considering CNC machining for your next project, aluminum may be the perfect material for your needs.

Best Aluminium Materials for CNC Machining

When it comes to CNC machining, aluminum is a popular material choice due to its versatility, low weight, and strength. However, there are different types of aluminum materials that can be used for CNC machining. Here are some of the best aluminum materials for CNC:

1. 6061 Aluminum

This is one of the most commonly used aluminum materials for online CNC machining. It is a versatile material that has excellent machinability, high strength, and good corrosion resistance. It is ideal for parts that require good weldability, moderate strength, and high resistance to corrosion.

2. 7075 Aluminum

This aluminum material is known for its strength and durability, making it ideal for parts that require high strength and low weight. However, it is a bit more difficult to machine compared to 6061 aluminum.

3. 2024 Aluminum

This aluminum material is commonly used in aerospace and aircraft industries due to its high strength-to-weight ratio. It has good machinability but is not as corrosion-resistant as 6061 or 7075 aluminum.

4. 5052 Aluminum

This is a non-heat treatable aluminum alloy that is easy to form, stamp, and weld. It has good corrosion resistance and is ideal for parts that require good formability and low weight.

When selecting the best aluminum material for CNC machining, it is important to consider the specific needs of your project, including strength, weight, and corrosion resistance. A professional CNC machining service provider can assist you in selecting the ideal aluminum material for your project.

Aluminum CNC Machining Parts Service

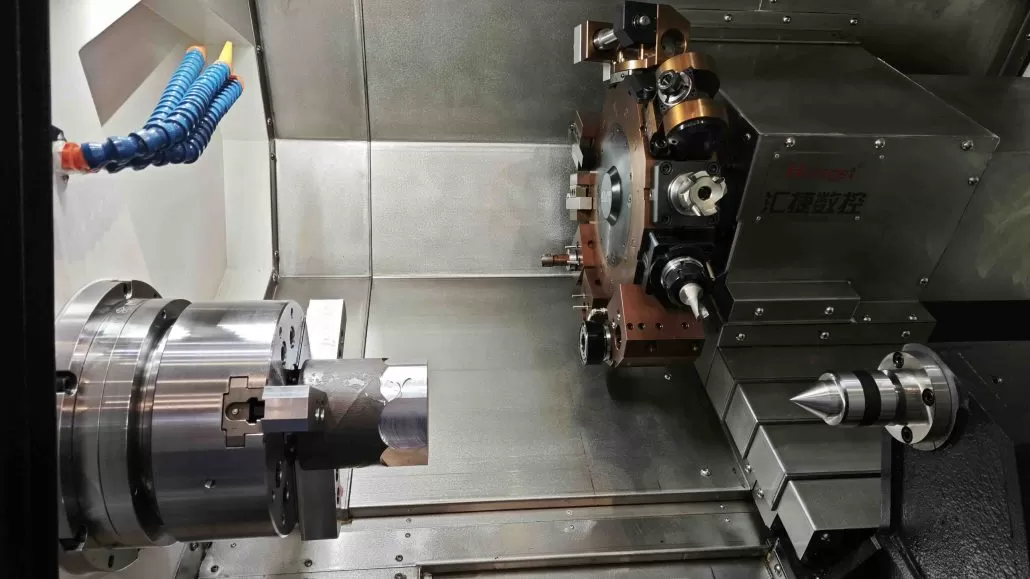

Aluminum CNC machining is a process that uses computer numerical control (CNC) technology to create precise and complex parts from aluminum material. This process is ideal for producing high-quality parts that meet the exact specifications of the customer.

Our company offers aluminum CNC machining parts service that utilizes state-of-the-art equipment and expert technicians to produce parts that meet the highest standards of quality and precision. Our services include:

- CNC milling

- CNC turning

- CNC drilling

- CNC tapping

We can produce parts of various sizes and shapes, from simple to complex designs, to meet the unique needs of our customers. Our team of experienced engineers and technicians work closely with our customers to ensure that their requirements are fully met, from design to final production.

We use only top-quality aluminum material in our production process to ensure the durability and longevity of our parts. Our aluminum CNC machining parts are widely used in various industries, including aerospace, automotive, medical, and electronics.

At our company, we are committed to providing exceptional service and quality products to our customers. Contact us today to learn more about our aluminum CNC machining service and how we can help you with your next project.

FAQ

Aluminum is a popular choice for CNC machining due to its versatility, low weight, and strength. It is also a relatively inexpensive material that is readily available, making it a cost-effective option for many manufacturing applications. In addition, aluminum is highly resistant to corrosion, making it an ideal material for parts that will be exposed to harsh environments.

When selecting the best aluminum material for your CNC machining project, it is important to consider the specific needs of your project, including strength, weight, and corrosion resistance. You should also consider the cost and availability of the material, as well as any other special requirements that may be necessary. A professional CNC machining service provider can assist you in selecting the ideal aluminum material for your project, based on your specific needs and requirements.

CNC machining offers several benefits for aluminum parts, including increased precision, faster production times, and the ability to create complex shapes and designs. CNC machines can produce parts with extremely tight tolerances, making them ideal for applications where precision is critical. In addition, CNC machines can create parts more quickly and efficiently than traditional machining methods, which can help reduce production costs. Finally, CNC machines can create complex shapes and designs that would be difficult or impossible to produce using traditional machining methods.

No, there are many other materials that can be used in CNC machining, including steel, brass, copper, and plastics. However, aluminum is one of the most commonly used materials due to its many benefits.

Aluminum is a popular material choice for CNC machining due to its versatility, low weight, and strength. When selecting the best aluminum material for your CNC machining project, it is important to consider the specific needs of your project, including strength, weight, and corrosion resistance. A professional CNC machining service provider can assist you in selecting the ideal aluminum material for your project, based on your specific needs and requirements.