As cycling continues to gain popularity around the world, so does the demand for high-quality, durable bike parts. Anodized CNC turning bike part manufacturers are at the forefront of producing top-notch components that are both lightweight and strong. In this article, we’ll explore the technical process of CNC turning, the benefits of anodizing, and the leading manufacturers in the industry.

CNC Turning: The Technical Process

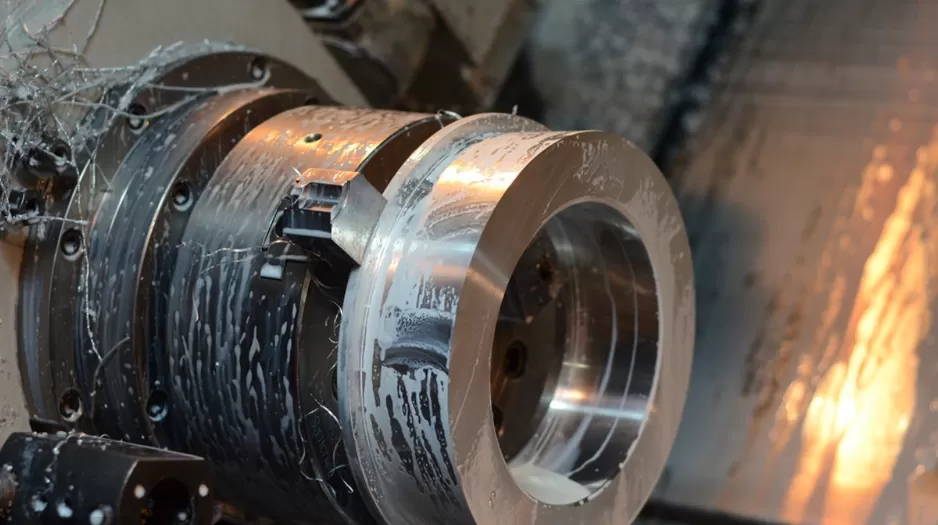

CNC turning is a computer-controlled machining process that utilizes specialized machinery to create precise, complex shapes from raw materials. The process starts by feeding a cylindrical block of material, such as aluminum or steel, into a rotating chuck. The spinning material is then cut by a stationary cutting tool, which is programmed to remove material in a specific pattern. This process allows manufacturers to create intricate shapes and finishes with a high degree of accuracy.

The Benefits of Anodizing

One of the key advantages of anodizing is its ability to increase surface hardness and corrosion resistance. Anodizing is an electrochemical process that forms a thin, protective layer on the surface of aluminum and other metals. This layer is harder than the underlying metal, making it resistant to scratches and abrasion. Anodized finishes also provide excellent resistance to corrosion, making them ideal for use in harsh environments.

Anodizing can also be used to create a range of colors and finishes. By varying the materials used in the anodizing process, manufacturers can produce finishes that range from bright, reflective surfaces to matte, textured finishes. This makes anodizing a popular choice for custom bike parts, where aesthetics are just as important as functionality.

Leading Anodized CNC Turning Bike Part Manufacturers

When it comes to finding the best anodized CNC turning bike part manufacturers, there are several key factors to consider. Quality, price, and lead time are all important considerations, as is the manufacturer’s ability to produce custom designs. Some of the leading manufacturers in the industry include:

- Longsheng – Longsheng specializes in CNC turning services and offers a range of anodized finishes to choose from. Their high-quality products and competitive pricing make them a popular choice among bike enthusiasts.

- Velo Orange – Velo Orange is known for their high-quality bike components, including anodized CNC turned parts. They offer a variety of finishes and materials to choose from, making it easy to find the perfect part for your bike.

- Industry Nine – Industry Nine is a popular choice for high-end mountain bike components, including anodized CNC turned parts. They offer a range of custom finishes and designs, as well as quick turnaround times.

Conclusion

Anodized CNC turning bike part manufacturers play a critical role in producing high-quality, durable components for cycling enthusiasts around the world. By understanding the technical process of CNC turning and the benefits of anodizing, cyclists can make informed decisions when choosing bike parts. With leading manufacturers like Longsheng, Velo Orange, and Industry Nine, it’s easier than ever to find high-quality anodized CNC turned parts for your bike.