sheet metal fabrication is a critical process that plays a vital role in the manufacturing of various components and systems across different industries. Its versatility, precision, and cost-effectiveness make it an essential part of modern manufacturing processes. With its numerous applications, sheet metal fabrication is expected to remain a key manufacturing process in the years to come.

Applications of Sheet Metal Fabrication

Sheet metal fabrication is a versatile process that is used in a variety of industries. Some of the most common applications of sheet metal fabrication include:

1. Automotive Industry

Sheet metal fabrication is widely used in the automotive industry for the manufacturing of various components. This includes the production of car bodies, chassis, engine components, and more.

2. Aerospace Industry

The aerospace industry heavily relies on sheet metal fabrication for the production of aircraft components. This includes the manufacturing of wings, fuselage, and other structural components.

3. Construction Industry

Sheet metal fabrication is also used in the construction industry for the production of HVAC systems, ductwork, roofing, and other structural components.

4. Electronics Industry

The electronics industry uses sheet metal fabrication for the production of enclosures, chassis, and other components for electronic devices.

5. Medical Industry

Sheet metal fabrication is used in the medical industry for the production of medical equipment, surgical instruments, and other devices.

These are just a few examples of the many applications of sheet metal fabrication. With its versatility and precision, sheet metal fabrication is an essential process for many industries.

Sheet Metal Fabrication Techniques

Sheet metal fabrication is the process of forming, shaping, and joining metal sheets to create various products. It involves several techniques that are used to cut, bend, and shape metal sheets to specific dimensions and shapes. In this document, we will discuss some of the most common sheet metal fabrication techniques.

Cutting Techniques

There are various cutting techniques used in sheet metal fabrication. Some of the most common ones are:

Shearing

Shearing is the process of cutting a sheet of metal using a machine that applies a straight-line cutting force. It is used to create straight cuts in the sheet metal.

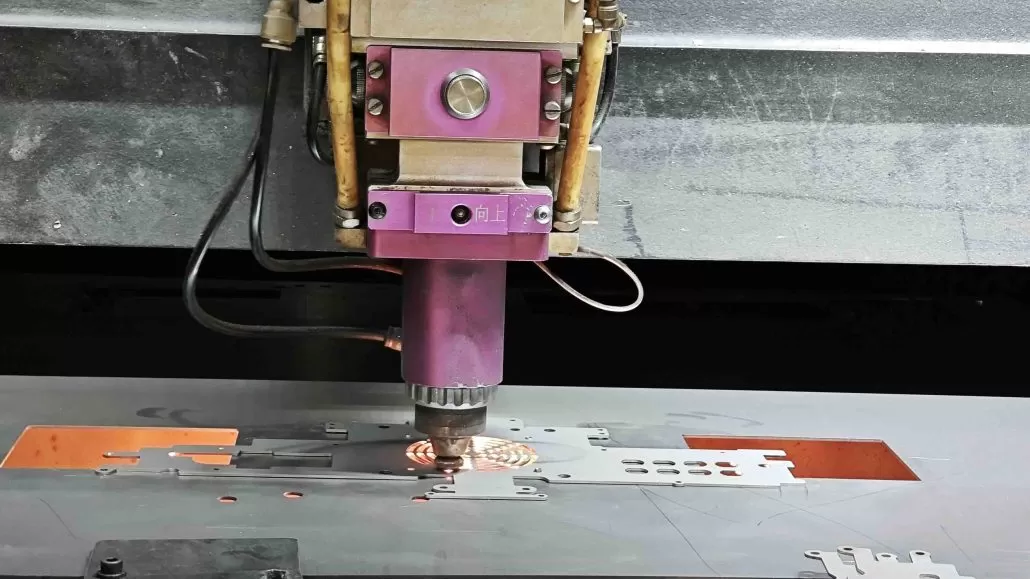

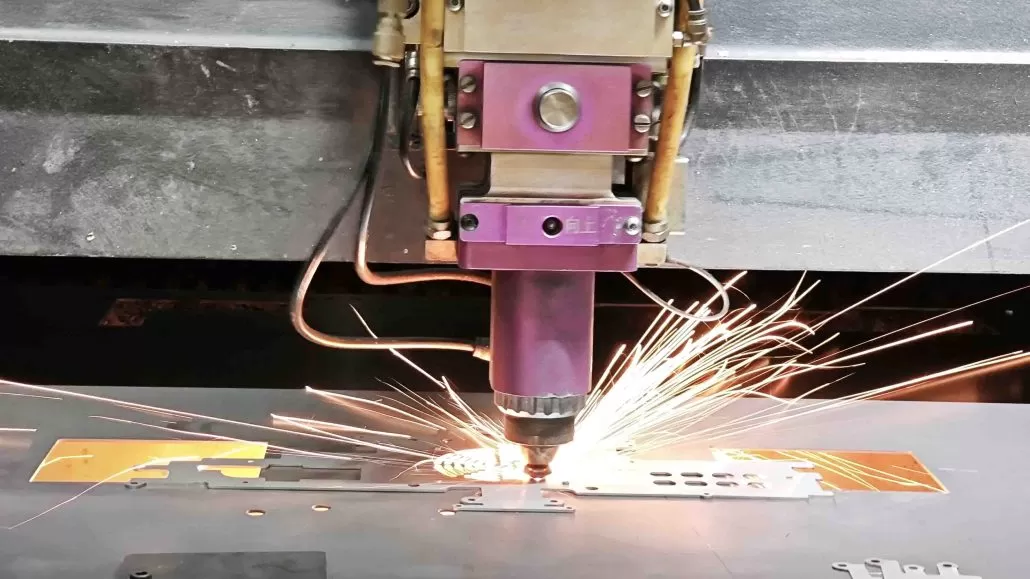

Laser Cutting

Laser cutting uses a high-powered laser to cut through the metal sheet. It is a precise cutting technique that is used to create complex shapes.

Waterjet Cutting

Waterjet cutting uses a high-pressure stream of water to cut through the metal sheet. It is a versatile cutting technique that can be used to cut through a variety of materials.

Bending Techniques

Bending is the process of deforming a metal sheet to a specific angle or shape. Some of the most common bending techniques are:

V-Bending

V-bending is a technique that uses a V-shaped die to bend the metal sheet to a specific angle.

Roll Bending

Roll bending is a technique that uses a set of rollers to bend the metal sheet into a cylindrical shape.

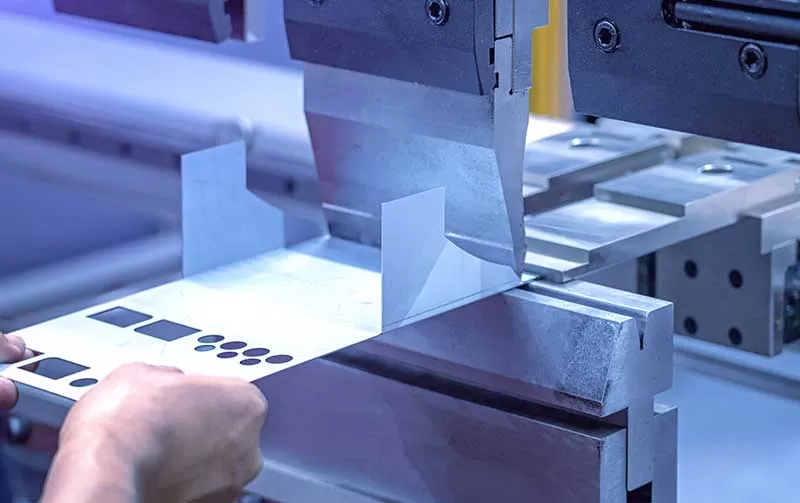

Press Brake Bending

Press brake bending is a technique that uses a hydraulic press to bend the metal sheet to a specific angle.

Joining Techniques

Joining is the process of connecting two or more metal sheets to create a larger structure. Some of the most common joining techniques are:

Welding

Welding is the process of melting two metal sheets together using heat. It is a strong and permanent joining technique.

Riveting

Riveting involves punching a hole in the metal sheets and using a rivet to hold them together. It is a fast and reliable joining technique.

Adhesive Bonding

Adhesive bonding involves using a special adhesive to bond two metal sheets together. It is a clean and efficient joining technique.

In conclusion, sheet metal fabrication involves several techniques that are used to cut, bend, and join metal sheets. By understanding these techniques, manufacturers can create high-quality sheet metal products that meet their customers’ needs.

Sheet Metal Fabrication Materials

Sheet metal fabrication is a process that involves cutting, bending, and shaping metal sheets into various products. The quality of sheet metal used in the fabrication process is essential in determining the final product’s strength, durability, and overall quality. Here are some of the commonly used sheet metal fabrication materials:

Steel

Steel is one of the most commonly used metals in sheet metal fabrication. It is highly durable, strong, and resistant to corrosion, making it ideal for use in harsh environments. Steel is available in various grades, each with unique properties that make them suitable for different applications.

Aluminum

Aluminum is another popular sheet metal fabrication material due to its lightweight, corrosion-resistant properties, and excellent strength-to-weight ratio. It is commonly used in the aerospace and automotive industries, where weight reduction is critical.

Stainless Steel

Stainless steel is a highly durable and corrosion-resistant material that is perfect for applications that require high levels of hygiene, such as food processing and medical equipment. It is also commonly used in the construction industry due to its aesthetic appeal and durability.

Copper

Copper is a highly conductive and malleable material that is ideal for electrical applications. It is also commonly used in architectural applications due to its aesthetic appeal and durability.

Brass

Brass is a combination of copper and zinc, making it highly durable and resistant to corrosion. It is commonly used in decorative applications due to its aesthetic appeal and ability to be polished to a high shine.

In conclusion, choosing the right sheet metal fabrication material is crucial in ensuring the final product’s quality and durability. The materials mentioned above are just a few of the many options available, and each has unique properties that make them suitable for different applications. When selecting a material, it is essential to consider factors such as strength, durability, corrosion resistance, and aesthetics.

Sheet Metal Fabrication Service

Sheet metal fabrication involves the manufacturing of metal structures by cutting, bending, and assembling processes. This service is essential in various industries such as construction, automobile, and aerospace.

Our company offers sheet metal fabrication services that cater to a wide range of needs. We use high-quality materials and equipment to ensure the precision and durability of our products. Our team of experts is highly skilled and experienced in handling all kinds of sheet metal fabrication projects.

We provide a variety of fabrication services, including laser cutting, punching, bending, welding, and finishing. Our laser cutting service uses state-of-the-art equipment to cut metal sheets with great accuracy and speed. Our punching service is ideal for producing holes, slots, and other shapes in metal sheets. Our bending service can create different angles and shapes in metal sheets. Our welding service uses advanced techniques to join metal parts together. Finally, our finishing service provides the final touches to the metal structure to ensure a polished and professional look.

We pride ourselves on providing our clients with high-quality, cost-effective sheet metal fabrication solutions. We work closely with our clients to understand their needs and requirements, and we deliver our projects on time and within budget.

Contact us today to learn more about our sheet metal fabrication services and how we can help you with your next project.

FAQ

Sheet metal fabrication is the process of creating metal structures by cutting, bending, and assembling thin metal sheets.

A wide range of metals can be used in sheet metal fabrication, including stainless steel, aluminum, copper, brass, and carbon steel.

Sheet metal fabrication is used in a variety of industries, including aerospace, automotive, construction, and manufacturing. Common applications include metal enclosures, brackets, panels, and frames.

Sheet metal fabrication techniques include cutting, punching, bending, welding, and finishing.

Machining is the process of shaping metal parts by removing material from a solid block. Sheet metal fabrication, on the other hand, involves working with thin metal sheets to create structures.

Look for a company with experience in your industry and a track record of delivering high-quality products on time. Ask for references and check online reviews.

When designing a sheet metal part, consider the material thickness, bend radius, and tolerance requirements. Work closely with your sheet metal fabricator to ensure the design is manufacturable.

To reduce the cost of sheet metal fabrication, consider using off-the-shelf materials and standard sizes. Minimize the number of parts and simplify the design to reduce labor and material costs.

We hope this FAQ has helped you better understand sheet metal fabrication. If you have any other questions or would like to discuss your sheet metal fabrication needs, please contact us.