If you are in the automotive industry, you know that quality and precision are everything. The production process needs to be reliable, efficient, and cost-effective. And that’s where custom injection molding comes in. Longsheng is a leading provider of injection molding services in Tennessee, specializing in producing high-quality automotive parts that meet our customers’ specifications.

What is Automotive Injection Molding?

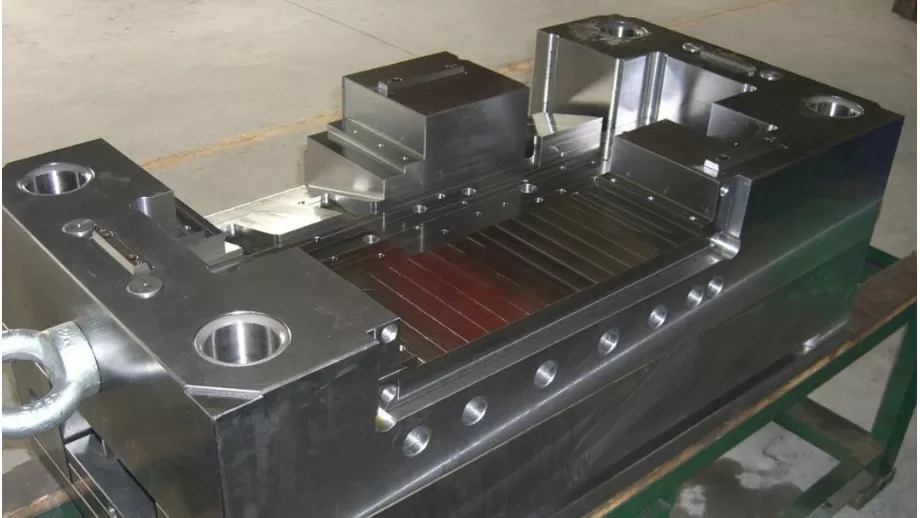

Injection molding is a manufacturing process used to produce parts or products by injecting molten material into a mold. The process is highly efficient and can produce complex shapes with high precision and consistency. The automotive industry uses injection molding to manufacture parts such as bumpers, dashboards, and interior trim components. The process is ideal for large-scale production, and it can help automotive manufacturers reduce costs while maintaining high quality.

Why Choose Longsheng for Your Injection Molding Needs?

Longsheng has extensive experience in producing automotive parts that meet our customers’ expectations. We use state-of-the-art injection molding machines and have a team of skilled technicians who are experts in the field. Whether you need prototypes or high-volume production runs, we can help you achieve your goals.

Our strengths:

- Customized solutions: We understand that every customer has unique needs. That’s why we offer customized solutions to meet your specifications.

- High-quality materials: We use only the highest quality materials to ensure the durability and reliability of your automotive parts.

- High capacity production: Our production capacity is geared towards high-volume orders, meeting short lead times with quality parts.

- Cost-effective services: We offer competitive pricing that helps you reduce costs and improve your bottom line.

Why Choose Injection Molding for Your Automotive Parts?

Injection molding offers numerous benefits for the automotive industry, such as:

- Reduced tooling costs: Because injection molding requires only one mold, it can significantly reduce tooling costs compared to traditional machining, which requires multiple tools.

- High precision and consistency: Injection molding produces parts with high precision and consistency, ensuring that each part is identical to the others.

- Faster production times: Injection molding can produce parts faster than traditional machining, helping you meet tight deadlines.

- Improved material utilization: Injection molding can optimize material utilization, minimizing waste and reducing your overall materials cost.

Conclusion

If you’re looking for a reliable and cost-effective way to produce automotive parts, injection molding is the way to go. With Longsheng’s expertise and experience, you can expect high-quality parts that meet your specifications. Our customized solutions, high-quality materials, and high-capacity production make us an ideal partner for your injection molding needs. Get in touch with us today to learn more about how we can help you achieve your goals.