Automobile rubber injection molding plays a very important role in automobile manufacturing. It not only helps to achieve the lightweight design of the car, improve fuel efficiency and environmental performance, but also has excellent physical performance, sustainability and environmental protection. In addition, the high repeatable and scalability of rubber injection molding makes it one of the preferred processes for automobile manufacturers in mass production. In this article, we will guide you through the process of evaluating automotive rubber injection molding suppliers so that you can make informed decisions and have great confidence in your choice. Let’s get started!

Introduction to automobile rubber injection molding

Automotive rubber injection molding is a key manufacturing process for the production of various rubber parts necessary for the automotive industry. The technique involves the injection of molten rubber material into the mold to produce parts with precise size and shape.

History and evolution of rubber injection molding

Rubber injection molding has a long history, dating back to the middle of the 20th century. The process was originally developed to improve the efficiency and quality of rubber parts manufacturing and has developed significant significantly. Innovation in machinery and materials has transformed it into a complex technology widely adopted in the automotive industry.

Importance in the automotive industry

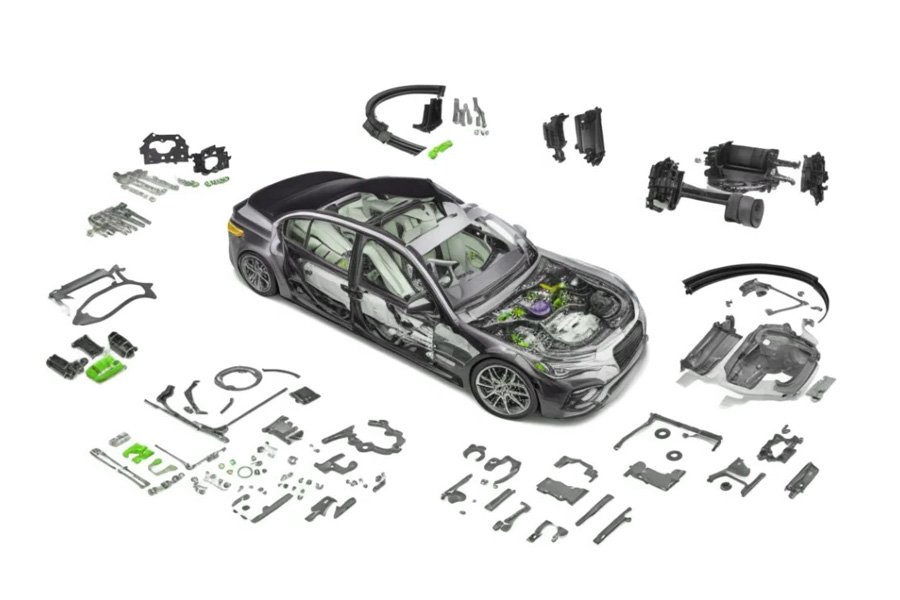

Rubber parts are very important in automobiles and play various functional and structural roles. From seals and washkets to suspension liners and engine supports, these parts ensure reliability, safety and performance of the vehicle. The precision and efficiency of rubber injection molding make it indispensable in automobile manufacturing.

Key applications

- Seals and gaskets: Rubber seals and washkets form indestructible barriers against leaks, protect fluids such as oil, coolant and fuel, ensure optimal engine performance and prevent environmental contaminants.

- engine support:The rubber engine bracket holds the engine to the chassis of the vehicle, effectively inhibiting the engine movement, reducing noise and vibration to the passenger compartment, and ensuring a quiet and comfortable driving experience.

- Skylight: Rubber seals and gaskets around the skylight provide water barriers against leaks and protect the vehicle from rain and moisture, ensuring seamless integration of the skylight while maintaining the weatherproof integrity of the vehicle.

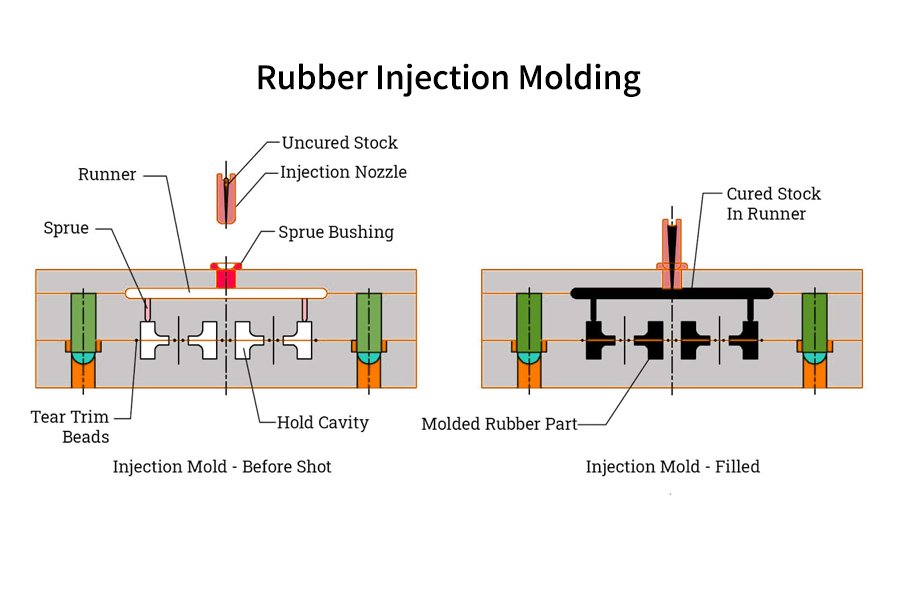

The working principle of automobile rubber injection molding

Automobile injection molding process is known to provide many benefits to automobile manufacturers. Let’s dive into the details of how the process works:

Step 1: Use the CAD software to create a virtual model with the desired parts.

Step 2: Use the model to produce a mold for injecting the molten material.

Step 3: Inject the material into the mold at high pressure and cool it until solidified.

Step 4: Use specialized machines to pop up and collect parts so that they can be sent for assembly or further finishing processes.

Supplier’s roles and status

Automobile rubber injection molding suppliers play a key role in the automobile manufacturing industry chain, and occupy an important position. They are not only important partners of automobile manufacturers, but also promoters of technological innovation, quality guarantors, cost controllers and industrial chain integrators. With the continuous development of the automobile industry, the role and status of automobile rubber injection molding suppliers will be more prominent. For enterprises that want to produce high quality automotive rubber injection molding products, it is crucial to find the right plastic injection molding company. Automotive rubber injection molding suppliers can understand customer needs, have the expertise to produce quality parts and be able to deliver on budget.

Provider’s Advantages

Low cost

Injection molding processing equipment and mold manufacturing cost is relatively low, suitable for small batch and large variety production. This allows automotive rubber injection molding suppliers to offer products at more competitive prices to meet the needs of automobile manufacturers.

The product material is diverse

Injection molding rubber production process is suitable for various hardness and material of rubber products processing. This means that automotive rubber injection molding suppliers can provide a variety of rubber parts with different materials and performance according to the needs of automobile manufacturers.

High product accuracy

Injection molding machine can process rubber products with high precision, so that the production of rubber products accurate size, smooth surface, no margin, no defects, no crushing, etc. This helps to improve the overall performance and safety of the car.

High molding efficiency

Injection molding process can quickly and accurately produce large quantities of high-quality rubber products. Its high level of automation, does not need too much manpower operation, thus improving the production efficiency.

The processing speed is fast

The injection molding process can quickly produce complex shaped parts, which helps to shorten the production cycle and meet the needs of automobile manufacturers for delivery time.

Strong customization

By adjusting the injection mold and process parameters, automotive rubber injection molding suppliers can produce parts of different shapes, sizes and properties to meet the personalized needs of automobile manufacturers.

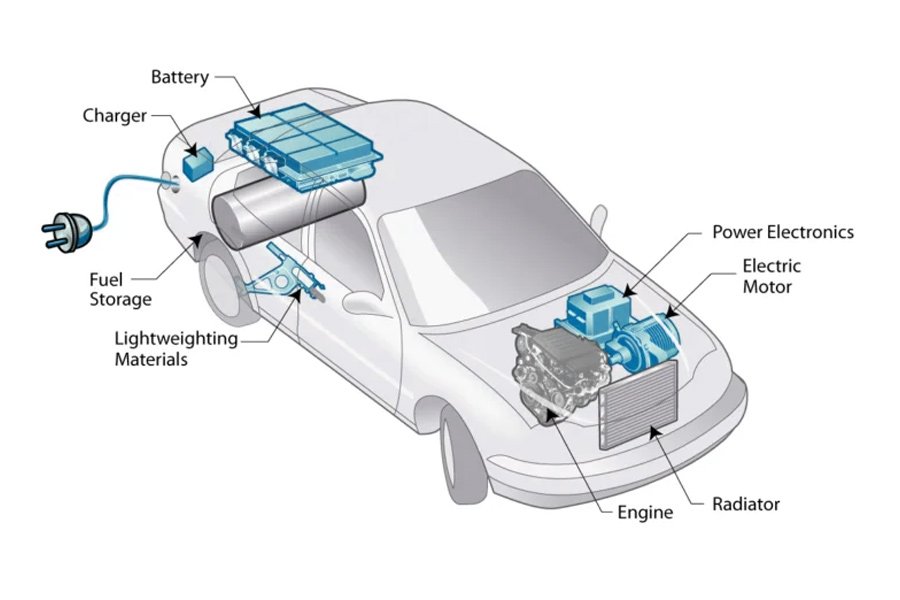

light weight

Because of its relatively low density, plastic reduces the overall weight of the car compared to metal materials, thus reducing the amount of fuel used. Over the past few years, auto makers have struggled to develop a lightweight material to replace traditional materials, such as steel and aluminum, and to use them to make car bodies. This will help auto makers meet their vision of saving energy and making emissions less.

Supplier’s disadvantage

1.The technical threshold is high

The successful implementation of the injection process depends on a degree of technical proficiency and accumulation of experience, otherwise difficult to ensure high quality and excellent performance of the final product. With the development of technology in the automobile industry, people pay more and more attention to vehicle safety. Automobile safety is one of the most important factors affecting consumers’ choice of models, and the increasing proportion of plastic used in automobile parts also brings great pressure to automobile manufacturing enterprises. Therefore, suppliers of automotive rubber injection molding need to continuously invest in R & D and technical training to enhance their technical capabilities.

2.Raw material prices fluctuate greatly

The price of rubber raw materials will be affected by multiple factors such as the market supply and demand, the international political and economic conditions, and the price often fluctuates greatly. The development of the automobile industry continuously increases the demand for rubber, but due to the large number of automobile production enterprises in China and their different sizes, the market competition is becoming increasingly fierce. This situation may make the automotive rubber injection molding suppliers face the problem of cost instability, thus affecting their profit potential.

3.Environmental pressure increases

With the increasing awareness of environmental protection and the continuous improvement of environmental laws and regulations,the suppliers of automobile rubber injection molding must deal with stricter environmental standards. These new challenges will force the automotive industry to reassess the environmental impact of their products when they are manufactured, transported and used. In order to follow the relevant laws, they need to invest more in resources and energy to reduce pollution in production and reduce waste emissions.

4.Market competition is fierce

In order to cope with the fierce market competition environment, the suppliers of automobile rubber injection molding not only have to face the fierce competition between the same industry, but also have to deal with the competitive pressure of the suppliers from other countries and regions.This requires automotive rubber injection molding suppliers to continuously improve product quality and service level to maintain market competitiveness.

Why Choose Longsheng For Your Automotive Rubber Injection Molding Needs?

Do you want to transform your innovative thinking into specific products? In the plastics industry, we provide not only technical services, but also a way to build close relationships with our customers. We are the service provider of plastic injection molding that you can fully trust. We can provide the best quality service to our customers at any time. With our excellent expertise and top customer service, we have the ability to help you make plastic products with a unique design. Whether you want to be personalized or mass-produce, we have the ability to meet all your needs.

Multi-Material Processing Capacity

- We have the ability to deal with all kinds of materials, no matter what material parts processing, we can provide professional service solutions.

Provide Personalized And Customized Services

- What you need, what our team customized for you, must package you satisfied.

No Minimum Order Volume

- This unrestricted ordering of plastic molded parts helps to increase efficiency and reduce production costs, thus making your production process more competitive.

Fast Deliver

- Our production process is efficient and flexible, which can ensure the timely completion of customer orders and meet the needs of emergency projects.

Longsheng’s Injection Molding Process

| option | technology |

| Request Parts Quotation | By uploading your design file to request a quote, our engineers will provide a response within 2 hours and start your project. |

| DFM Feedback | Conduct a feasibility review of your design to ensure that I, Moen, can produce functional molds that meet your requirements. |

| Mold Flow Analysis | Using mold flow analysis software to predict the flow and mode of action of molten materials within the mold can help improve and ensure the quality of the parts. |

| Part Mold Production | Start producing mold tools according to your requirements. |

| T1 Sample Verification | Before starting the production of plastic parts, we provide T1 samples for customer inspection to ensure the accuracy and quality of the parts. |

| Low Volume Production | After the sample trial production is completed, small batch production will begin. We utilize advanced processing technology to efficiently produce plastic parts. |

| Quality Control | We conduct strict inspections on the functionality, size, and appearance of plastic parts to ensure that they meet your specifications and requirements. |

| Delivery | After strict inspection, we will deliver your injection molded parts to you as soon as possible. |

The reason for choosing Longsheng

At Longsheng, whether you need the manufacturing of prototype parts or mass production, we have the corresponding capabilities and experience to meet your needs. We are committed to providing reliable and high-quality components to assist you in achieving success in the fiercely competitive automotive market.

Quick Quotation

Simply upload CAD files and you can quickly understand manufacturing costs within 2 hours. You can also keep up with the latest information on order status at any time.

Rapid Prototyping

Longsheng has extensive experience in prototype manufacturing, ensuring that your components are completed with high quality in the later stages of the design and manufacturing process.

ISO Certification

Longsheng is a manufacturing company certified by ISO 9001, which means we adopt internationally recognized best practices to develop your products and ensure they meet standard requirements, regardless of the complexity of the design.

On Demand Custom

Our automotive parts manufacturing process is fully customizable, based on your specifications, dimensions, materials, and surface requirements to ensure that your unique needs are met.

Fast Delivery

We are committed to providing fast manufacturing and delivery to meet your production needs, while also providing you with greater flexibility to quickly respond to market changes. Longsheng is your partner for automotive parts needs.

Conclusion

If you are looking for high-quality, cost-effective injection molding solutions for automobile manufacturing, Longsheng’s custom injection molding service may be your best choice. With a combination of expertise, quality, flexibility and customer service, the company is able to deliver customized solutions that meet project-specific requirements and exceed expectations. Contact Longsheng immediately to learn more about their abilities and how they can help you achieve your goals.

FAQs

How to evaluate the supplier’s qualifications and experience?

Check whether the supplier has the relevant production license, quality management system certification (e. g. ISO 9001), and automotive industry-specific standard certification (e. g. IATF 16949).Learn about the suppliers’ history and expertise in automotive rubber, including which automakers they have served for, and their successes in the field. Investigate the r & d capabilities and technical capabilities of suppliers, including their R & D team, technology patents and new product development speed, etc.

How to ensure the quality of the products provided by the suppliers?

The supplier is required to provide detailed product specifications, material list and quality control plan. At the same time, the supplier is required to conduct the sample test, and provide the relevant test report and conformity certificate. Conduct regular on-site audit of suppliers to understand their production process, equipment status and quality management system. Set clear quality standards and acceptance standards, and specify the liability for breach of contract in the contract.

How to negotiate a reasonable price with the suppliers?

Understand the price level of similar products in the market to negotiate with suppliers. Discuss the cost composition with the suppliers to understand their pricing basis. Negotiate prices with suppliers according to the purchase volume, delivery time and other factors, and strive for better discounts and discounts. The price terms and payment methods are specified in the contract to ensure the rights and interests of both parties.

How to ensure the delivery time of suppliers?

Communicate fully with the suppliers to clarify the delivery time requirements and production plan. Understand the production capacity and inventory status of the suppliers and ensure that they can meet the delivery requirements. Set a reasonable delivery time margin to deal with possible accidents. Regularly regular delivery time for suppliers and take corresponding measures for suppliers who fail to deliver on time.

How to evaluate the quality of service of suppliers?

Understand the technical support and after-sales service system of suppliers, including their response speed, problem solving ability and customer satisfaction. When communicating with suppliers, observe their expertise and communication skills to ensure that they can accurately understand the needs and provide effective solutions. Collect feedback and reviews from other customers to understand the quality of service and reputation of suppliers. Clarify the terms of service and liability for breach of contract in the contract to ensure that the supplier can provide quality service.

resource

Aluminium supplier selection for the automotive parts manufacturer

Crush simulation of automotive chopped fiber composite structures by de

A sustainable molding process for new rubber products from tire recycling